Solar panel manufacturing process: from cell to module

During lay-up, solar cells are stringed and placed between sheets of EVA. The next step in the solar panel manufacturing process is lamination.

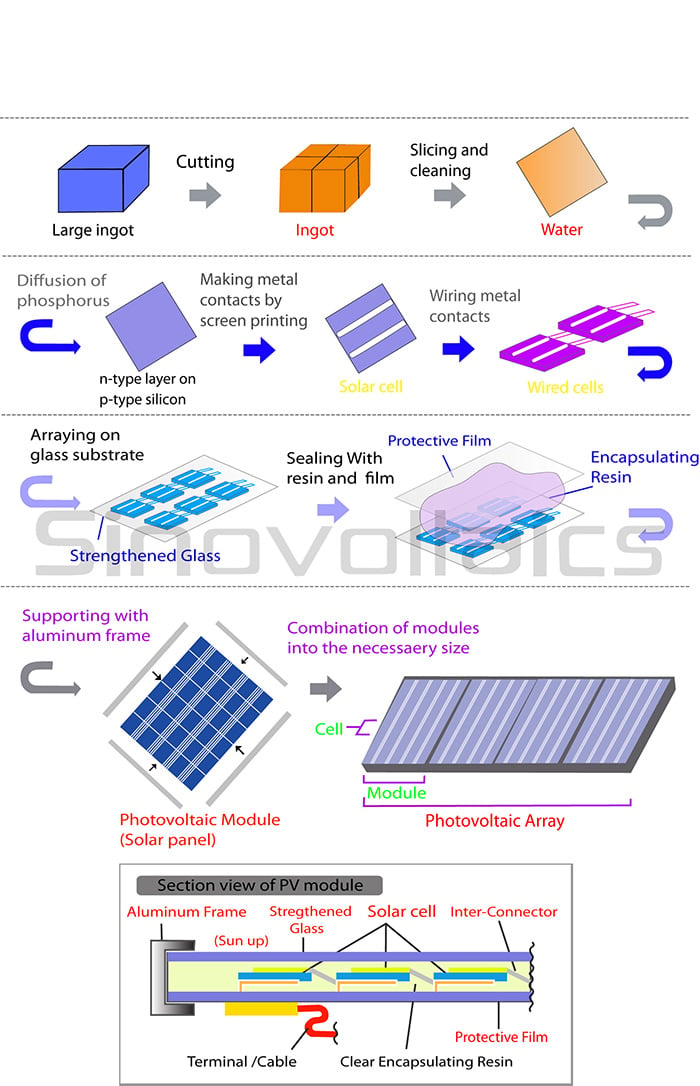

Solar panel manufacturing process

After having produced the solar cells and placed the electrical contacts between the cells, they are then wired and subsequently arrayed.

Solar panel lamination

Sealed into ethylene vinyl acetate, they are put into a frame that is sealed with silicon glue and covered with a mylar back on the backside and a glass plate on the front side. This is the so-called lamination process and is an important step in the solar panel manufacturing process. Finally, the structure is then supported with aluminum frames and ready is the PV module. The following illustration depicts the whole process:

Solar Panel Manufacturing Process

Power output check

Before the ready panel can be sold it must sustain a testing procedure to ensure its power output.

Flash test

Apart from a visual test of the panel, the testing included a flash test that measures the open-circuit voltage (VOC), voltage at maximum power point (VMP), short-circuit current (ISC), current at maximum power point (Imp), maximum power (Pm (W)) and the fill factor (FF). The parameters of the modules are measured at standard test conditions (STC).

Standard testing conditions (STC)

STC specifies a temperature of 25°C and an irradiance of 1000 W/m2 with an air mass 1.5 (AM1.5) spectrum. These correspond to the irradiance and spectrum of sunlight incident on a clear day upon a sun-facing 37°-tilted surface with the sun at an angle of 41.81° above the horizon. This condition approximately represents solar noon near the spring and autumn equinoxes in the continental United States with the surface of the cell aimed directly at the sun.

P R Panigrahi

on 18 Jun 2019Jitendra Bijlani

on 13 Dec 2020H s Bhopte

on 14 Jan 2019Clince Babu

on 14 Sep 2018Dumisani Shipalana

on 11 May 2018Tascom

on 03 Apr 2018guruprasad

on 06 Feb 2018Shubham Babar

on 24 Jan 2018Uttam Napte

on 11 Jan 2018Mohit Agarwal

on 29 Nov 2020Jitendra Bijlani

on 13 Dec 2020Ramesh Varma

on 07 Nov 2021Shashi Kant Rai

on 01 Feb 2022