Flash Test: technical background and importance

Solar Flash Tests (or: Sun Simulator Tests) measure the output performance of a solar PV module and are a standard testing procedure at manufacturers to ensure the conforming operability of each PV module.

Solar flash testing - technical background

The appliance used for measuring the output performance conformity of a solar PV module is call flash test machine or sun simulator. During a flash test the PV module is exposed to a short (1ms to 30 ms), bright (100 mW per sq. cm) flash of light from a xenon filled arc lamp. The output spectrum of this lamp is as close to the spectrum of the sun as possible. The output is collected by a computer and the data is compared to a exactly calibrated reference solar module. The reference data is geared to the power output calibrated to standard solar irradiation. The results of the flash test are compared to the data specifications of the PV module type which - in abbreviated form - are printed on the label on the module's back.

What exactly is measured during the flash test?

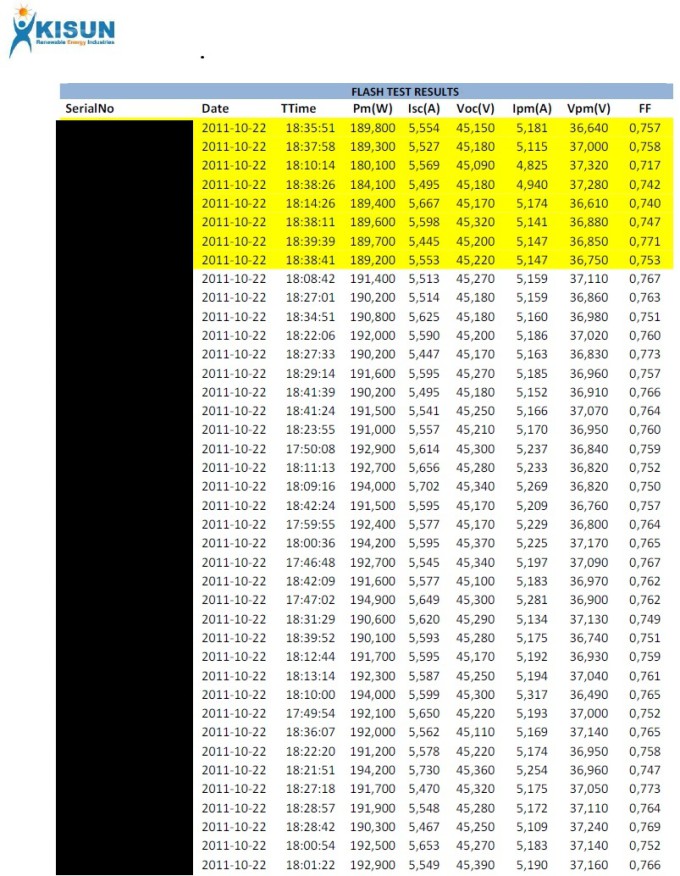

Module parameters are measured at standard test conditions (STC). The temperature has a crucial effect on PV module performance. As the temperature of a module increases two things happen. First: the voltage output of each cell decreases. Second: the current output of each cell increases slightly, overall reducing the maximum power output in Watt (Pm (W)) of the module. The used standards do not necessarily reflect actual operating conditions. A flash test results sheet usually lists all tested modules and the specific test results. In the example flash test results sheet below (courtesy of Sinovoltaics), the yellow marked panels indicate Pm(W) values below the tested module type's minimum 190Wp (at -0% tolerance requirement). They do not suffice the -0% tolerance requirement and therefore have to be replaced.  Flash test results - Sinovoltaics.com

Flash test results - Sinovoltaics.com

For further information on the other testing and performance parameters in the table above you will find detailed information in this topic about Solar Panel Output Parameters.

Why use a reference PV module for the flash test?

The reference module is a module of which the exact power is meticulously determined in advanced, mostly in collaboration with a certification body or testing lab of renowned quality testing institutions, such as VDE or TUV. With the use of the reference PV module, the flash test can be configured correctly. Professional solar PV module manufacturers have two reference solar panels available for each power type. The specifications of the reference solar panels have to be tested and determined by a qualified laboratory.

Why is correct calibration of the flash test important?

Only after correctly calibrating the sun simulator, it is possible to accurately measure the PV module's Current-Voltage (I-V) parameters.  Solar Module Flash Test

Solar Module Flash Test

Are flash test results provided by PV manufacturers reliable?

We wish they were! As the flash test machine is configured according to the reference module, one can imagine that the flash test can be configured to produce any desired data. Even though every manufacturer (should) provide the flash test data of all solar panels ordered, performing own flash tests on-site is necessary to confirm if all quality criteria are met. It is very easy to manipulate flash test results and adjust related output parameters so that they look real. Tips and further reading: A way to receive a flash test that is performed by an independent third party, is to have Sinovoltaics perform a Quality Inspection for you. Download example flash test results (courtesy of Sinovoltaics).

Vijesh Jaiswal

on 15 Mar 2018mukhtar shaykh

on 05 Jun 2017Pradeep Kumar

on 26 Jul 2016Daft P.

on 30 Jun 2015Niclas

on 02 Jul 2015Daft P.

on 25 Jun 2015Umesh Upadhyay

on 10 Jan 2017Niclas

on 26 Jun 2015Daniel Vlad

on 04 Apr 2023