In our ongoing series about solar energy storage technologies we explored in the previous part 2 the functioning and advantages and disadvantages of lead-acid (PbA) batteries, still the most popular battery technology used with solar off-grid systems.

Now in this part 3, we will have a closer a look at lithium-ion batteries which – though being a relatively new technology – have in recent years increasingly gained popularity as solar energy battery banks, with worldwide installed electrical energy storage capacity already standing at over 100 MW for all kinds of electronics, thus having already surpassed PbA batteries.

Lithium-ion batteries – structure and shapes

Lithium-ion batteries are a relatively young technology type, in use since the early 1990s. They are currently the most applied battery type among all consumer electronics, especially telecommunication devices, with a total market revenue share of over 35%.

As the name suggests, lithium-ion batteries – abbreviated as Li-ion batteries or LIB – is a rechargeable battery type using lithium (Li) as the main raw material. Lithium is relatively rare and the lightest (alkali) metal known to mankind, mainly found and produced in Australia, Chile, and China and with Rockwood Lithium, FMC, and SQM being the largest suppliers of lithium chemicals in the world.

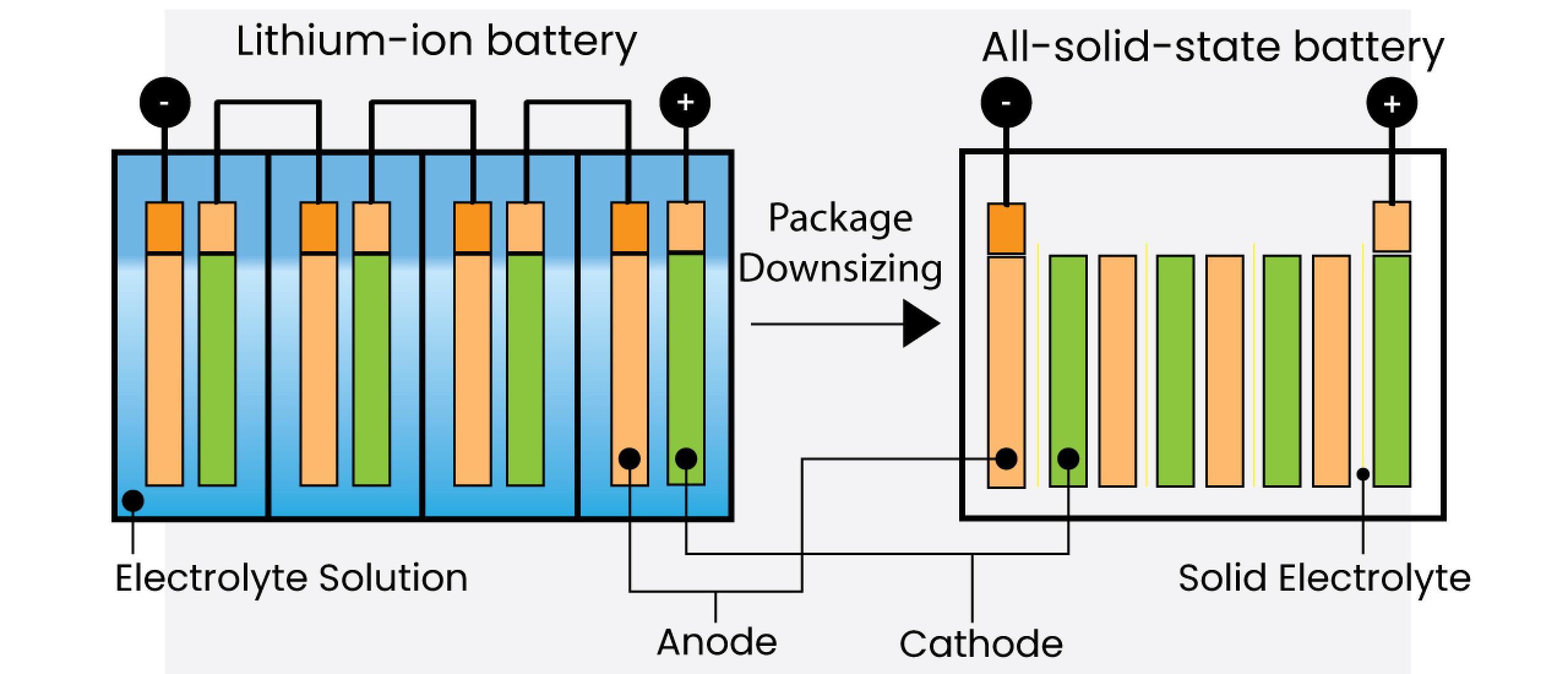

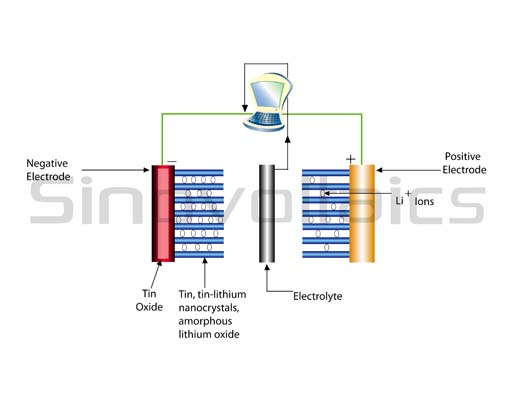

Basically, the Li-ion battery cells make use of lithium ions movements between the anode and cathode terminals – the negative and positive electrode – thus converting chemical energy to electrical energy during discharging and vice versa during charging.

The anode of a Li-ion cell is usually made up of carbon (or any other similar nonmetal), the cathode is made of various types of metal oxides and the electrolyte is generally made up of a lithium salt solution.

There are different available shapes of the single cells of a Li-ion battery: cylindrical type with/ without terminals, used in larger portable devices, pouch type, as for example used in smaller lightweight devices such as cell phones or digital cameras, and prismatic type.

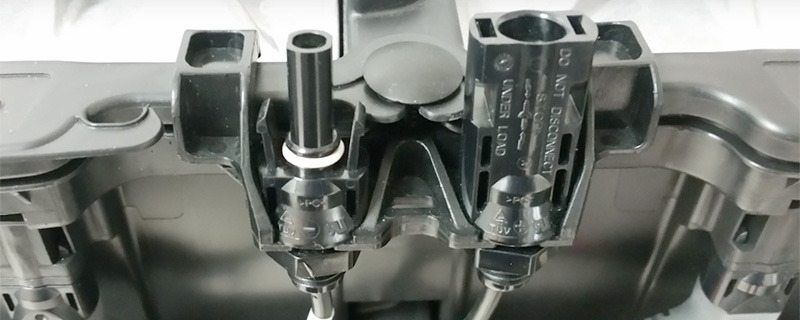

The prismatic-shape Li-ion batteries are the largest type and are overwhelmingly used for large applications, such as electric vehicles, but also increasingly as a battery banks for larger off-grid installations, including solar PV systems.

They generally have riffles on the sides which serve as air-ducts so to cool the battery. An example of a typical prismatic-type Li-ion battery is the Nissan Leaf Li-ion battery as seen on this article’s featured image.

There are various commercially available and researched chemistry bases in terms of the electrodes of Li-ion batteries, and each chemical base comes with diverging properties of the battery in terms of factors such as energy density, cycle life or charging time.

Main chemical bases for Li-ion batteries

The main lithium-based chemical bases used with Li-ion batteries are cobalt, manganese and phosphate. Each base has different properties and resulting electrochemical properties as well as raw material and manufacturing costs.

1. Cobalt (Co)

Cobalt (Co) is the major chemical basis applied with Li-ion batteries in which the anode is usually made of the lithium-carbon compound and the cathode of lithium cobalt oxide (LiCoO2) (also: Lithium Cobalate or Lithium-Ion-Cobalt), abbreviated as Li-cobalt or shorter: LCO batteries.

Due to its comparably high energy density of 150-190 Wh/ kg and high capacity of 140 mAh/ g, Li-ion technology is usually used in digital cameras, cell phones, and portable computers, yet they are significantly more expensive than other types.

The life cycle of LCO batteries is 500 – 1000 cycles with, as compared to the other main chemical bases, a relatively long average charge time of 2-4 hours.

2. Phosphate (Po)

Similar to LCO batteries, Li-ion batteries on a phosphate (Po) basis use a lithium-carbon anode, yet their cathodes are made of lithium iron phosphate (LiFePO4) and are therefore abbreviated as Li-phosphate or LFP batteries.

Compared to the other Li-ion battery types, LFP batteries have a relatively low energy density with 90 – 120 Wh/kg, yet they offer quite high capacity, longer life cycles of 1000-2000 cycles, a more constant discharge voltage of 2.8V/ cell, and charge times of maximum 1 hour. In view of these advantages, LFP batteries are the major Li-ion battery type of interest for the solar PV industry.

3. Manganese (Mn)

Manganese (Mn)-based Li-ion batteries have a hydrocarbon (HC) anode and are also called LMO batteries due to the cathode’s chemical composition of Lithium Manganese Oxide (LiMn2O4).

With 100 mAh/ g, LMO batteries have lower capacities than LCO or LFP batteries, yet due to their higher safety, low pricing (lowest among all chemical types) and a good energy density, life cycle, and charge ratio (maximum 1 hour), LMO batteries are especially popular as energy storage technology for medical devices.

Alternative battery types

Apart from LCO, LFP, and LMO batteries, there are many more types that offer even higher capacities, yet come with a higher price tag and are therefore still less used.

These types include NMC batteries with the cathodes made of Lithium Nickel Manganese Cobalt Oxide (LiNiMnCoO2) and Lithium Nickel Cobalt Aluminum Oxide (LiNiCoAlO2) or NCA batteries, both types are cobalt-based and with different quantity grades of the relatively toxic cobalt.

Due to its high capacities of around 150 and 170 mAh/ g respectively, NMC and NCA batteries are very interesting as storage technologies for electric cars.

Other currently researched Li-ion types include Lithium Titanate (Li4Ti5O12) or LTO, which is gaining importance in power-trains and grid storage, as well as Lithium Oxide (Lithium Air), which offers gasoline-like energy densities and is comparably clean by emitting and adding oxide during charge and discharge.

Top 6 advantages of Li-ion batteries

Li-ion batteries come with many significant advantages of which we list the main ones as follows:

- Lightweight, they are used in portable devices such as mobile phones, laptops, and many electronic gadgets

- Low self-discharge when compared to other rechargeable batteries – about 10% at a normal room temperature level

- Broad discharge temperature frame of -20°C to 60°C

- Low maintenance

- Comparably high energy density with more research potential for even higher capacity

- Scalable, can be used as battery pack (many batteries connected in parallel) in order to serve high-power applications or devices such as electric cars and electric wheelchairs

Mercedes Benz – Lithium-Ion solar energy storage system at Intersolar Munich 2015

Top 6 disadvantages and limitations of Li-ion batteries

As nothing is perfect in this world, so are the Li-Ion batteries, which do have some limitations and disadvantages. Those are:

- Safe handling is required with Li-ion batteries because if they are overcharged, dropped, or over/under heated, there are chances for combustion leading to fire, therefore they are subject to more strict transport regulations

- Limited charge temperature frame of 0°C – 45°C

- Low overcharge tolerance

- Requirement of the protection circuit, limiting voltage and current

- More expensive than other established battery technologies such as PbA, however research has significantly brought down costs in recent years

- Aging. If not used for a prolonged period of time, there are chances that batteries may drain. Once they have drained completely, lithium-ion batteries cannot be recharged and have to be discarded. A way to slow down the aging is to store them at cool places at about 40% charge state

Conclusion

Being superior in terms of weight (more lightweight), volume (much smaller), better temperature performances, low self-discharge, lifespan, and with no requirement for maintenance as compared to LA batteries, the cost factor remains the main hurdle for Li-ion batteries in the PV industry, however, this hurdle is already falling.

Even though lead-acid batteries have been the dominating solar energy storage technology for years, with the decreasing costs of Li-ion batteries it is only a matter of time until they will gain increasing popularity among designers, manufacturers, and installers of off-grid PV systems.

TO OUR READERS:

Are you already using Li-ion batteries with your solar off-grid systems? How has it performed so far? We want to hear from you, comment or mail us!

Sources:

1) Battery University

2) IEA

3) FMC

Teodor

on 25 Jul 2015