At the 10th SNEC in Shanghai 2016, modules with so called “borderless” cell to cell interconnections were quite a hotly discussed technology trend, especially the Seraphim Eclipse.

Even though other PV module manufacturers as well have been embarking on the 0BB trend train with models which were shown during the SNEC 2016, Seraphim’s Eclipse was the major talk this year.

While there is progress made by plenty of manufacturers over the past years in cell efficiency increases, there are comparably few companies that bring to market innovations on the actual module design.

Current cell upgrades, including PERC solar cells, are now becoming increasingly popular amongst most manufacturers and will become mainstream within the next couple of years.

When visiting Seraphim’s booth we learned that this quite new model just recently was successfully certified to IEC standards and thus basically qualified for the markets. Reason enough for us to look at this new model.

What’s new about the Seraphim Eclipse?

Essentially, the solar cell and string lineup have been completely re-invented.

While recently Niclas wrote a popular article about solar cell busbar technologies and the clear trend of cells with an increasing number of busbars, akin to the design approach of California-based Solaria, USA and China-based manufacturer Seraphim comes with a design to eliminate busbars altogether.

How does it look?

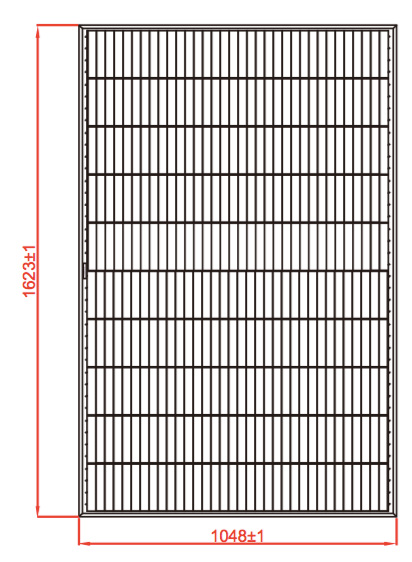

As can be seen in the photo below, the Seraphim Eclipse has a particular design feature: there is no longer any spacing between the solar cells.

The solar cell busbars have been completely eliminated and from the photo it appears that the solar cells are overlapping.. which is exactly the case!

Seraphim Eclipse

How is the Seraphim Eclipse made?

While the design and the manufacturing process of the Seraphim Eclipse is proprietary (patent pending), their head engineer was kind enough to give some hints about the design and explain why this design leads to certain advantages.

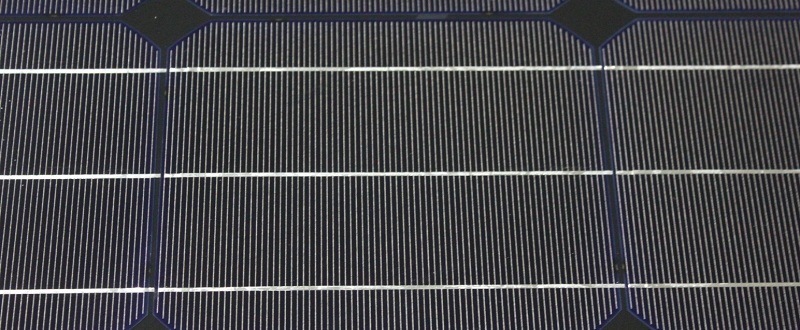

To start with, the Eclipse is made of cut solar cells, both poly and mono crystalline silicon (c-Si) models are available. These solar cells are laser-cut in 5 evenly-sized cell slices.

Instead of electrically connecting the solar cells in a string by soldering tab wire over the busbars, the busbar-less solar cell slices are slightly overlapping. The cells are connected with a conductive paste, which replaces busbars altogether.

What are the advantages of the Seraphim Eclipse design?

The Eclipse PV module comes with a number of advantages:

Increase of available cell space to absorb more sunlight

As seen in the photo above, there is no longer any spacing between the solar cells of each string. Additionally there aren’t any busbars on the solar cells itself. As a result, there is simply more cell surface available to absorb the sunlight.

Minimization of cell to cell electrical losses

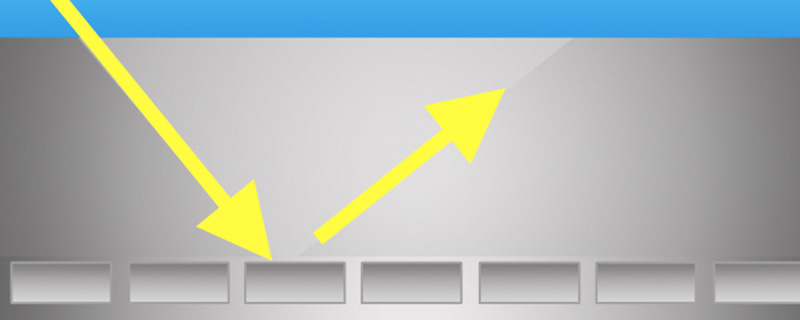

The advantage of interconnecting solar cell slices directly is that they produce a higher voltage and a lower current, which reduces potential losses. In order to come close to standard module voltages, the strings are placed in parallel while the Eclipse is divided into 2 parts that are connected in series. For that reason the junction box is placed in the middle back.

This is how the solar cells of a Seraphim Eclipse are placed:

Serpahim Eclipse – solar cell string design

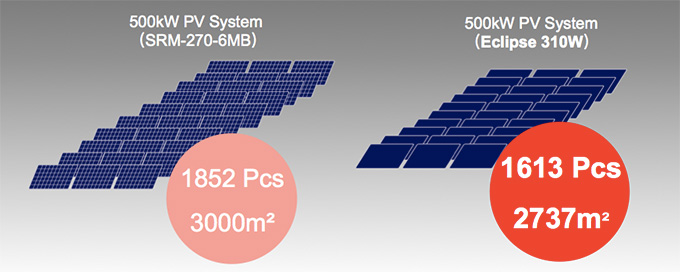

Save >8% of system space

Due to the more efficient use of cell space, overall space require for PV system installations is reduced as well:

Seraphim Eclipse and standard modules space savings compared

Efficiency increase at a low cost

Seraphim has applied an innovative module design and uses low cost, standard solar cells. In terms of costing this makes it attractive, especially IF the actual manufacturing cost of this module will be similar to a standard solar module.

Manufacturing may be a challenge?

One can imagine that instead of using 60 solar cells, assembling a solar module with 300 solar cell slices involves more steps and requires very accurate machinery for the module assembly.

As the company just acquired certification to major IEC standards, as readers of the latest edition of our Comprehensive Guide to Solar PV Module Certifications know this procedure generally involves factory audits by a certification body. Apparantly, this has been solved and the module is ready for mass production.

As Seraphim has introduced both a poly- and mono c-Si versions of the Eclipse, one may wonder if mono cells are a cost and space-efficient option since mono cells are not perfectly square. This means that part of the solar cell can not be used and will be turned into waste.

Conclusion

Despite potential cost- and space efficiency challenges with regards to mono c-Si models, the Seraphim Eclipse comes with some major advantages:

good aesthetics, a more efficient space/ performance ratio, lower shading and electrical losses by eliminating busbars and overall more compact space-saving PV system design. The fact that the company uses standard c-Si cells should make this product affordable, as long as the company manages to manufacture this (more complex) product efficiently.

While most Tier 1’s are now upgrading to PERC solar cells, it’s interesting to keep in mind that in the future the Eclipse design can be upgraded with PERC cells as well, which would turn it into a very high performance module.

For more information you may want to have a look at:

Serpahim Eclipse datasheet

Jinsung Kim

on 18 Jan 2017