What is Production Monitoring?

Production Monitoring is often referred to as a During Production Inspection (DUPRO) or In-line Inspection. Production Monitoring allows you to oversee the manufacturing of PV components from A to Z.

Our Production Monitoring services involve:

- Primary material conformity verification

- Compliance to Standard Operating Procedures (SOPs)

- Monitoring of internal quality control system

- Statistical tracking of defects and reworks

- Production and testing equipment maintenance and calibration

- Environmental conditions for each production area

- Overall monitoring of production abnormalities

What are the advantages of Production Monitoring?

Inspecting your PV components during manufacturing stage offers the following advantages:

- Improve and optimize the various production stages

early identification and correction of deviations and quality problems

Gain full insight on your PV product quality already during manufacturing

Reduce your costs: prevent any recalls / damage of your reputation by replacement of defect PV components prior to shipment

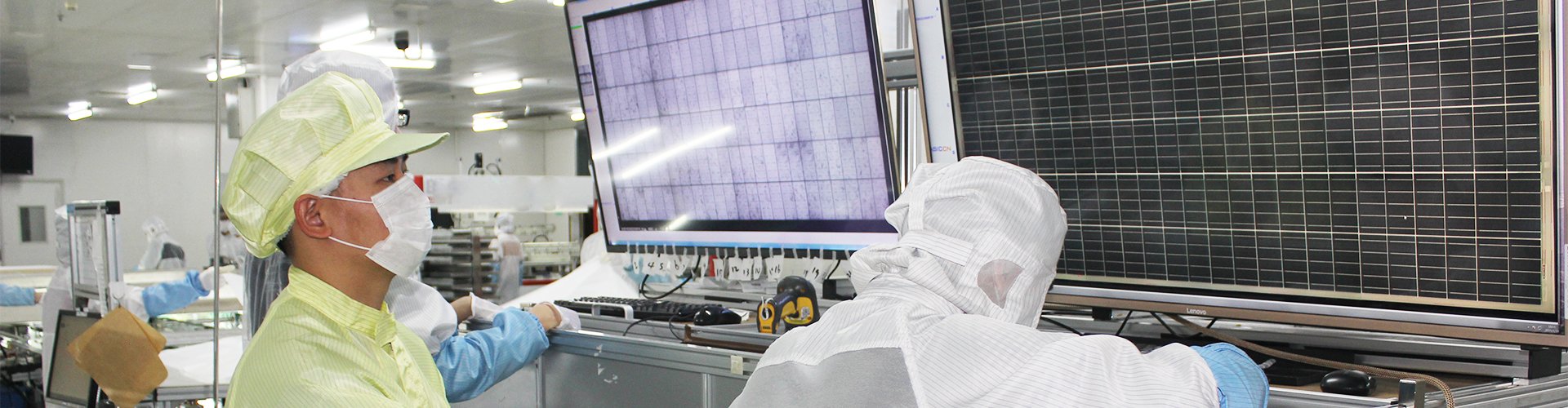

Quality inspections on-site at solar factories

How is Production Monitoring performed?

Sinovoltaics typically performs Production Monitoring for solar module purchases of 3MW+, and it's usually combined with Pre-Shipment Inspections.

Production Monitoring starts from day 1 of production, and you can count on our Quality Engineers to be present throughout the entire production process.

Production Monitoring is executed according to the following procedure:

- Client orders Production Monitoring with Sinovoltaics and the inspection is scheduled with the factory.

- As soon as production starts, our team of PV Quality Engineers will arrive on-site at the factory to review the entire manufacturing process.

- Any deviations and quality problems found will be directly solved on-site and communicated with our client.

- A detailed inspection report will be issued within 2-3 working days.

What other PV-specialized quality inspection services do we offer?

Sinovoltaics' PV component inspections can be conducted at all stages of the manufacturing process. Production Monitoring is usually complemented by an Pre-Shipment Inspection, and Packing and Loading Supervision. Sinovoltaics offers the following inspections:

- Production Monitoring

- Pre-Shipment Inspection

- Packing and Loading Supervision

- 100% Electroluminescence (EL) review

What are your benefits implementing ZERO RISK SOLAR?

Entrusting Sinovoltaics with the quality assurance of your PV components - your benefits:

- 100% independent from suppliers and manufacturers

- PV component-specialized quality engineers

- comprehensive quality testing with strict attention to detail

- apply our proprietary quality standards and inspection techniques

- detailed, confidential and fast inspection reporting