Solar panel micro cracks, or more precisely micro cracks in solar cells pose a frequent and complicated challenge for manufacturers of photovoltaic (PV) modules.

While on the one hand it is difficult to assess in detail their impact on the overall efficiency and longevity of a solar panel, they are one of the main sources of malfunctioning or even inactive cells.

However, micro cracks are nearly impossible to avoid and – in the long-run –will affect most solar panels, including ‘high quality’ ones. They are triggered by mechanical and chemical natural factors stressing the panel operating in field, such as hail, snow, sun, wind and severe cold.

Further stress factors are geared to the thermal cycles of the cells involving contracting, expanding and flexing metal contacts, solder and wire interconnects.

Potential Impact Micro Cracks

Even though they are nearly impossible to avoid in the long-run, their potential impacts pose quite a serious issue that should be addressed as early as possible – a requirement that is only insufficiently met during quality control at many manufacturers.

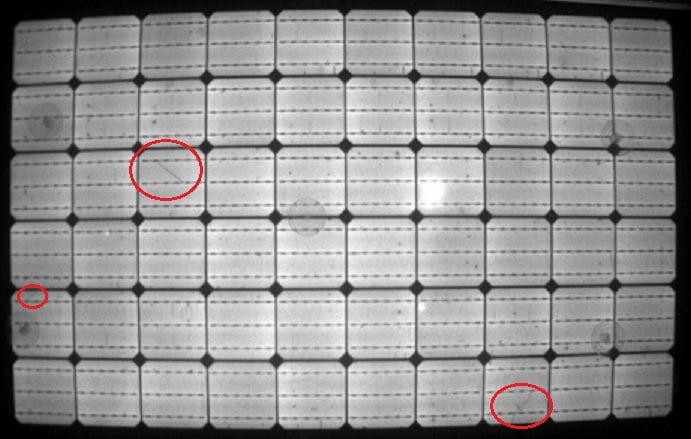

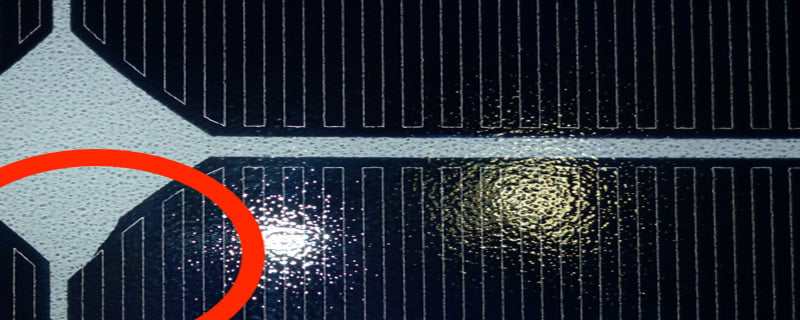

Micro cracks visible with Electro Luminescence (EL) test

Micro cracks may have various defect origins and result in rather “soft” outcomes such as yield-reducing shattering of parts of the affected cell up to mores severe impacts involving decreases of the short circuit current and cell efficiency.

Often, they are a result of mechanical forces or thermal stress. In the production process, micro cracks most frequently occur during lamination of the panel, especially when using certain EVA films with weak moisture impermeability.

If in such cases even slight moisture occurs it cannot easily evaporate which is particularly problematic in hot areas and environments. The moisture may in such cases pass through the micro cracks on the front of the laminate, followed by the oxidization of the contact fingers.

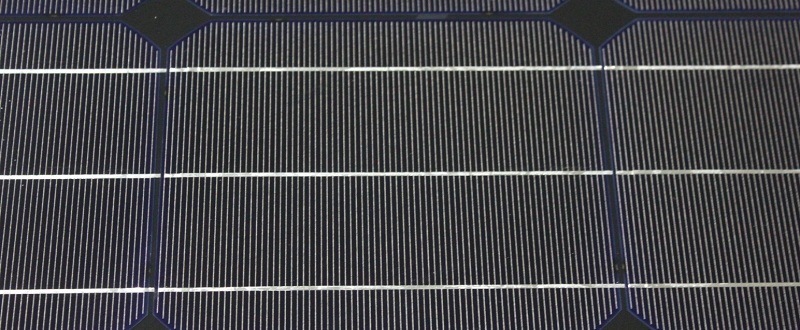

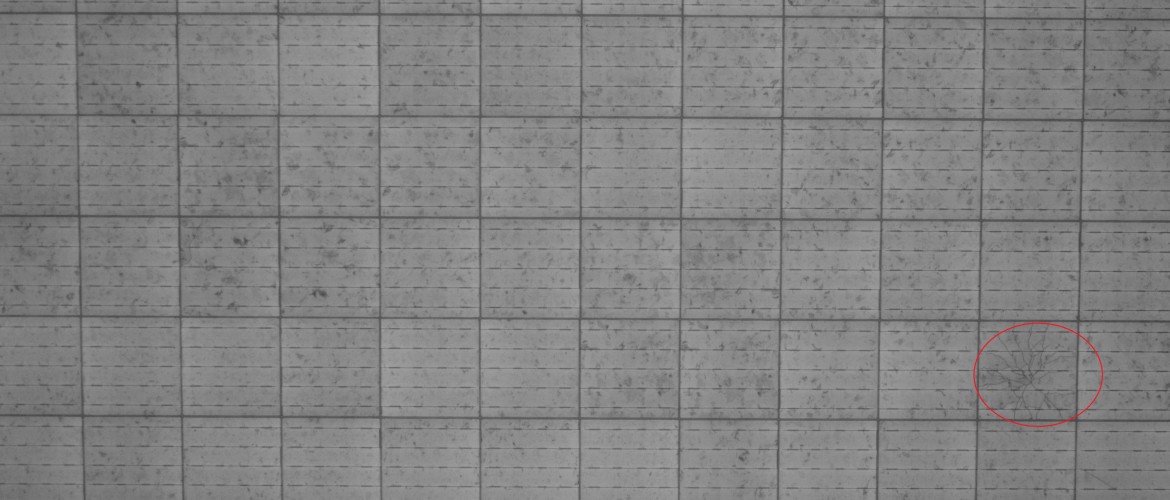

Micro crack in a mono-crystalline solar (PV) module

Micro cracks can also occur during manual soldering when varying thermal expansions of the copper and the silicon elements develop at temperatures above 300°C. Those temperature differentials can lead to the formation of micro cracks in the substrate and thus result in higher cell resistance.

Cracks potentially grow over a longer operational time and thus extend their malicious impact on the functionality and performance of a PV module, potentially triggering hot spots as well.

Undetected, micro-cracks can result in a less than expected field lifespan. They differ in size, location on the cell and impact quality.

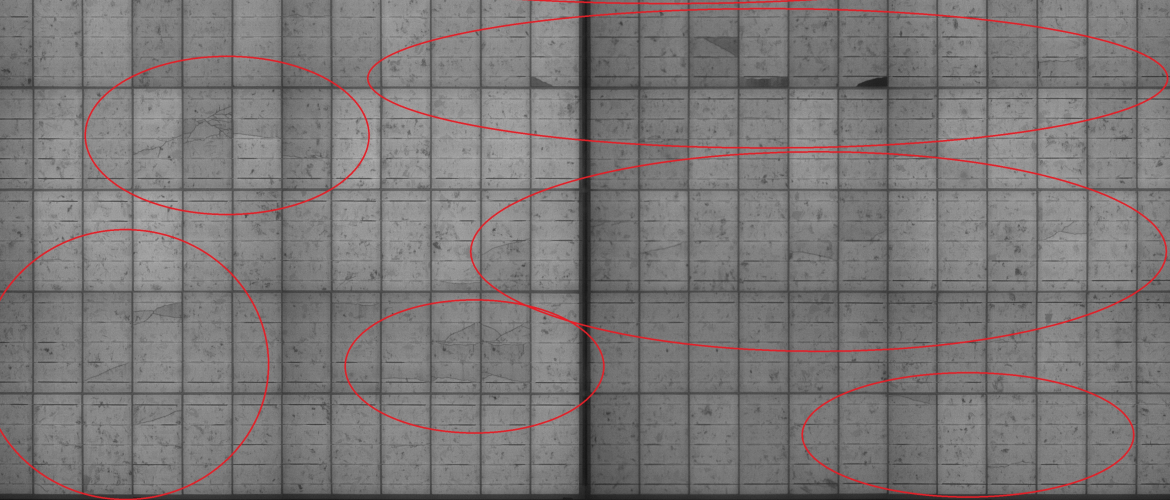

There are different quality testing methods to identify micro cracks of which electroluminescence (EL) or electroluminescence crack detection (ELCD) testing is one of the most applied method.

EL testing can detect hidden defects that were before untraceable by other testing methods, such as infrared (IR) imaging with thermal cameras, V-A characteristic and flash testing.

It is an image analysis and measurement process allowing to peer directly into the cells of a pv module and locate potential inherent defects.

EL test – defect cells

Optimally, EL testing is performed once before lamination so that the defect solar cells can be replaced and then again after (careful) lamination.

This procedure costs time and manpower which not all PV manufacturers are willing to invest in the quality of their produced solar panels.

Visually, micro-cracks may appear in form of so called snail trails on the cell structure. However, snail trails – as a long-term impact sign – can also be the result of chemical process causing the surface of the cell to change and/ or hot spots.

Therefore, visual checking of PV modules alone is not an effective method to identify micro-cracks and should not replace a thorough EL test.

Solution: due diligence & panel quality testing

When you are purchasing solar panels, you should conduct EL testing on your panels and have them properly, safely packed before giving green light to the shipment. If importing from the Greater China region, Sinovoltaics can help you by performing independent quality inspections on-site at solar manufacturers.

Advantages:

- Replace defects prior to shipment

- Independent testing report

- 100% certainty about product quality

- Sinovoltaics has an international quality testing crew specialized not only in solar PV panels, but also inverters and mounting racks

Useful references:

a) Renewable Energy World – Minimizing micro cracks in solar cell interconnection during manual soldering

Jessie Angelaere

on 25 Jun 2015Ermal

on 10 Aug 2016serdar

on 14 Feb 2018Dricus

on 04 Mar 2018