AI-driven electroluminescence EL Testing Software for the removal of Micro Cracks from your PV modules and PV projects

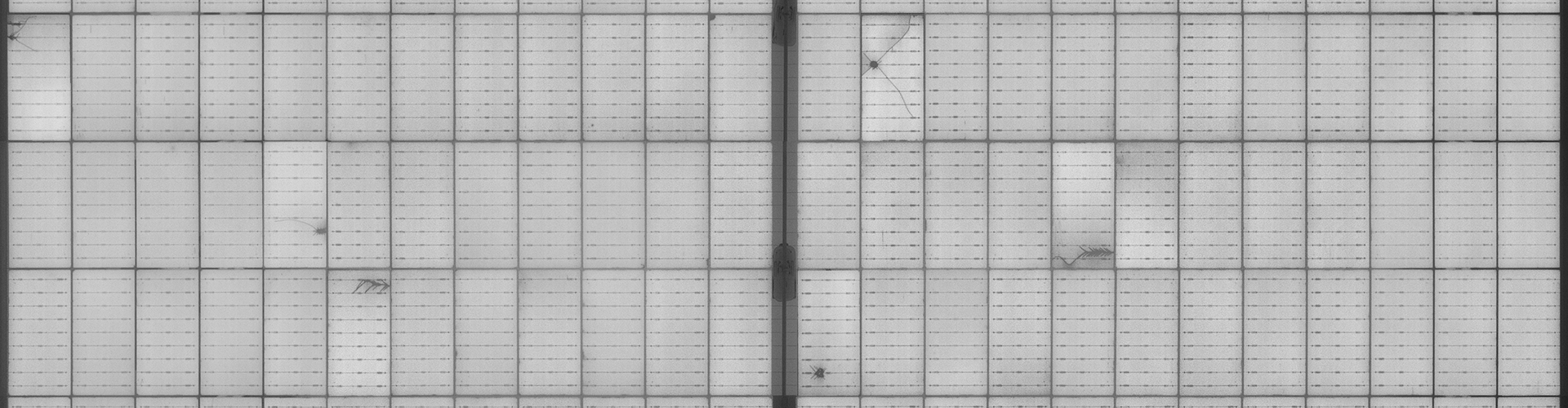

Micro cracks are the top defect found in PV test results and can seriously affect the performance of your solar power plant.

How to avoid this #1 defect that affects performance?

Through EL testing solar panels, with our solution: Sinovoltaics EL Mass Analysis (SELMA) software you can have peace of mind knowing your solar investment is well-protected. Improve your factory’s production with fast, high-accuracy electro luminescence analysis using advanced solar cell testers.

Remove 100% of serious micro-cracks from your PV shipments using AI driven Electro luminescence EL testing.

Advantages of EL Testing with SELMA:

- Up to 99% accuracy

- High-speed analysis: avoid delays and easily keep up with the factory’s production speed

- Trained with 10+ years of defect data

- Accepted by all leading Tier 1 manufacturers

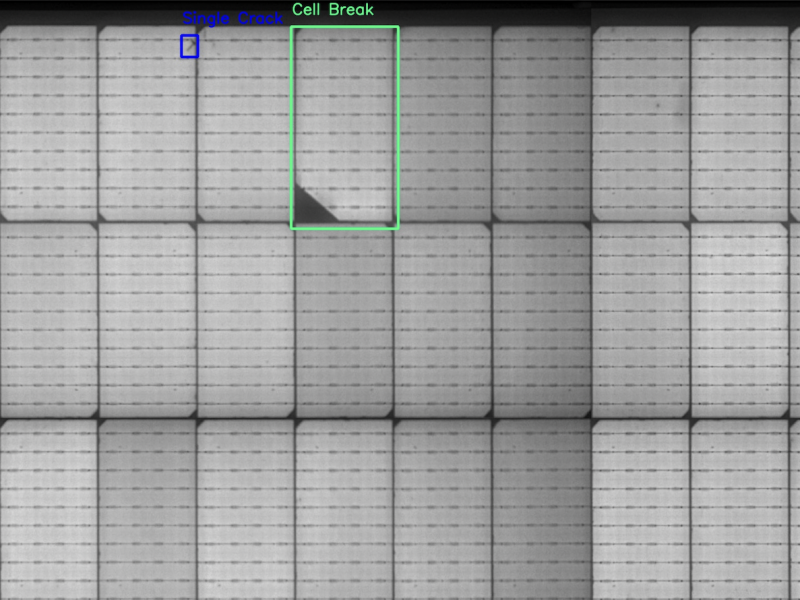

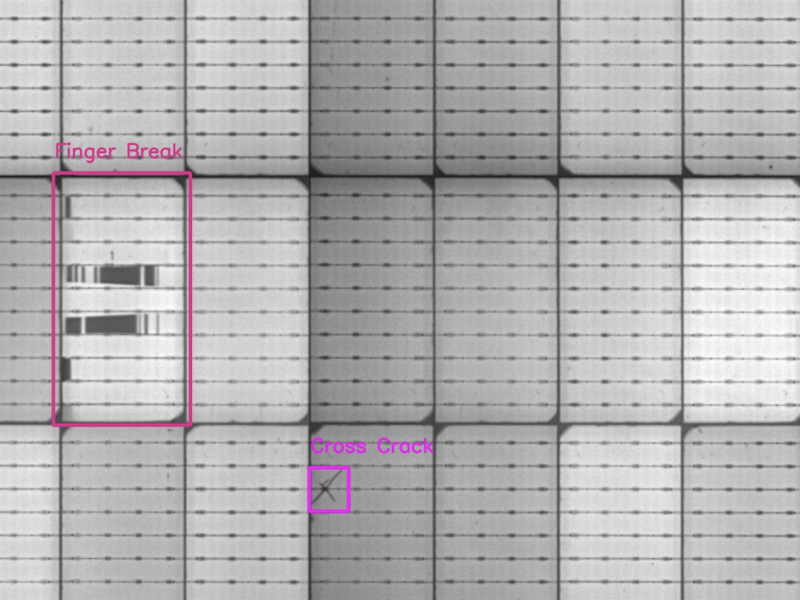

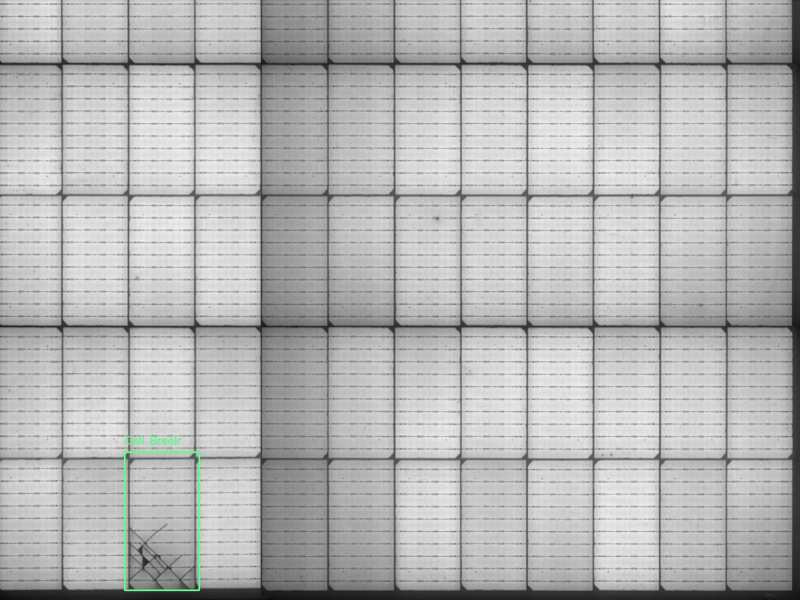

- Identification and classification of up to 15 cell-inherent defect types

- Improve silicon solar cell efficiency of your production and shipment

- Replace defective solar modules at the factory prior to shipment

Who can benefit from EL image testing?

- Developers PV projects

- EPCs

- Financiers

- Insurers

- PV module factories

Receive a quote? Fill out the form to inquire about our electroluminescence tests on panels performed with the highest standards.

What is Electroluminescence testing in solar?

Electroluminescence testing a solar module is a Non-Destructive Testing and Early Defect Detection EL inspection technique that uses the light emission phenomenon of photovoltaic (PV) cells to detect defects and failures in solar modules. When a current is applied to a PV cell, it emits light in the infrared spectrum, which can be captured by a camera and analyzed to reveal the quality and performance of the cell. Electroluminescence testing in solar panels uses advanced techniques to detect defects like micro cracks and broken cells, ensuring photovoltaic module efficiency.

EL testing allows for proactive replacement of faulty solar panels before they enter the field by preventing shipping faulty panels, EL testing captures defects such as bus bar contact failures and Potential Induced Degradation (PID) without halting production. Unlike other inspection techniques, EL testing provides a non-invasive method of identifying hidden defects that aren't visible through traditional visual inspections or I-V curve tracing.

Fill out the form below to discuss 100% EL testing on your solar modules at the PV factories in Asia.