Solar Water Pump System: key components

Solar Water Pump Pipes: Pipe Sizing Chart

Solar Water Pump Inverter: correct sizing essentials

Solar Tracking Water Pump Systems: optimal power yield

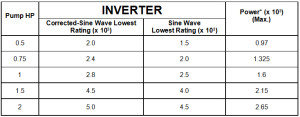

Solar water pump inverter sizing table[/caption]The standard average running power is usually between 10-20% with typically about 10% of power losses in the inverter. The modified sine-wave inverter will take the losses to 15% because the motor efficiency is affected negatively.

Solar water pump inverter sizing table[/caption]The standard average running power is usually between 10-20% with typically about 10% of power losses in the inverter. The modified sine-wave inverter will take the losses to 15% because the motor efficiency is affected negatively.