In the course of the increasing popularity and sales of micro-inverters even in commercial systems and beyond the U.S. market, the design of photovoltaic (PV) projects and as well the industry are changing dramatically.

Solar panel manufacturers already offer integrated “AC” modules with micro-inverters.

This article is an introduction to solar micro-inverters, outlining its advantages and disadvantages in comparison with traditional inverters.

Basic functions of Solar Micro-Inverters

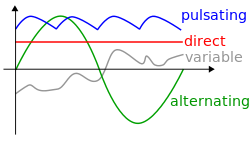

The cells of solar panels can only produce direct current (DC) electricity at a voltage that depends on each module’s technical design, location and sunlight conditions.

As alternating current (AC) is the form of electricity businesses and households are supplied with and consume, solar PV systems require Solar Micro-Inverters to convert this DC electricity – generated by the solar panels – into AC electricity.

Being key components of the solar panel array, the functions of an Solar Micro-Inverter go even beyond mere electric current conversion and include anti-islanding protection (AIP) and maximum power point tracking (MPPT).

In a PV system using string inverters, the panels are connected in series forming panel arrays that operate as a single big panel with higher normal volt rating.

The DC current power of that array is then converted by the inverter into AC voltage, which usually is 230V/ 50Hz in Europe and 240V/ 60Hz in North America.

Direct Current (red curve). The horizontal axis measures time; the vertical, current or voltage. Source: Wikipedia.org

Disadvantages of string inverters

As string inverters handle strings of panels which are technically treated as a single larger panel, the maximum output current of the string is only as high as the weakest panel in the string, which is in industry circles referred to as the Xmas-light effect.

Panels may perform weaker and their output drop significantly even in the event of minor manufacturing defects or when cells of the panel are shaded.

Another disadvantage of string inverters is that the MPPT system is geared to the whole array which in case of one panel operating at a different point can lead the system to output-lossing maximum power point mismatches.

Problematic is also that string inverters must be sized and chosen according to the whole system, require much high voltage DC wiring and consume much (scarce) space that must optimally be cool or offer good protective shading to the sensitive high-heat load inverter.

Solar Micro-Inverters

In contrast with central or string inverters which are connected to arrays of several solar panels, micro-inverters handle one single panel or even two panels (dual Solar Micro-Inverters).

Similar to the larger traditional devices, they convert the direct current (DC) electricity generated from that single (or two) module(s) into alternating current (AC) electricity.

Micro-inverters are usally attached at backside of a PV panel.

Solar Micro-Inverter

Being attached to a single or two panels, micro-inverters can much more specifically tune the output of each panel or two panels by applying individual MPPT and in this way optimize the yield of the whole system.

Shading or manufacturing defects of single panel parts or whole panels do in such installation not bring down the output of the whole string.

Output problems within a PV system can much easier be traced down to the poorly performing components – saving much time and maintenance costs.

Micro-inverters have lower heat loads than their large brother devices and are therefore less sensitive to overheating problems.

At the same time, they require significantly less wiring and less installation space being attached to the backside of a panel, enjoying cooling shading by the panel.

Moreover, the usage of micro-inverters allows for quicker and more flexible additions or replacements of panels within the whole system as there are no rating and size requirements to be met.

The major disadvantage of micro-inverters though has been its considerable higher pricing.

Nevertheless, this pricing gap is also increasingly diminishing, making micro-inverters a serious alternative even for larger commercial installations.

Conclusion

All in all, in technical and reliability terms, micro-inverters far outpace their string and central inverters counterparts.

This is also mirrored in the usually longer warranties for micro inverters geared towards the average estimated lifetime of a standard PV module (up to 25 years) as compared to that of a string or central inverter (5 years).

With the diminishing price gap between traditional and Solar Micro-Inverters and also the increasing need for flexible-to-adjust and cost-efficient-to-maintain PV systems, it is much likely that more and more large-scale projects will be using micro-inverters.

Rui Pires

on 16 May 2016Rogier

on 07 Feb 2014Pavlov F.

on 07 Feb 2014Kvetoslav M

on 29 Jan 2014Charly C.

on 29 Jan 2014Pete Vortes

on 28 Jan 2014Dricus

on 28 Jan 2014Michael

on 28 Jan 2014Karl D.

on 28 Jan 2014Ron

on 28 Jan 2014Peter Davis

on 23 Jan 2014