Multi Junction solar cells

Multi junction solar cells are solar cells that contain several p-n junctions. Each junction has a different band gap and is made to receive a different wavelength of light. This results in a highly efficient solar cell that have reached efficiencies of up to 43.5%.

Multi junction solar cells are not easy to produce and are currently extremely expensive. The costs are around USD 45,000 /m2. So how on earth can these multi-junction solar cells be cost effective? Multi junction solar cells are currently used in space and in the field of CPV, concentrated photovoltaics.

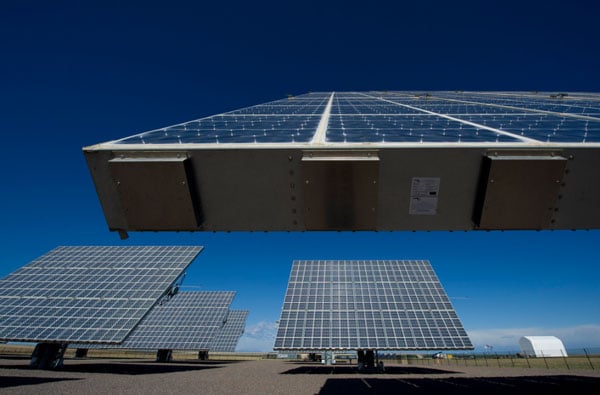

CPV

Multi-junction solar cells are still very expensive. Initially the only application for these solar cells has been in space. However when researchers started concentrating sunlight and point this at multi junction solar cells, the cells became price competitive for use in CPV power plant installation.

The lens is used to bundle the sunlight, which can be concentrated around 500 times. When the concentration factor is very high, the efficiency of the solar cells is drastically increased, making the solar cell more cost effective.

A tracker system is needed because the lens optimally bundles direct sunlight.

CPV – Amonix Solar

Disadvantages CPV:

- Expensive components. A CPV installation has a couple of expensive components: the optics system, the multi junction solar cell and the tracker. Manufacturers of this technology have been trying to lower the costs of these components. One solution can be to improve the lenses and eliminate the tracking system.

- Maintenance. A tracking system needs maintenance and for large scale projects it may lead to extra costs during the lifetime of the plant.

- Lifetime. Often overseen, but definitely an issue, is the lifetime of multi-junction solar cells that are used for CPV. When sunlight is bundled 500 times and concentrated on a small piece of solar cell, it brings a lot of stress to it. Not all researchers in this field are confident that the tiny multi junction cell can withstand this force for a long time.

Major breakthroughs in improved lenses need to be made in order to bring the costs for CPV down and make it compete with Silicon (Si) solar cells.

Gallium Arsenide (GaAs) solar cells

Gallium arsenide (GaAs) is a mixture of two elements, gallium (Ga) and arsenic (As). Gallium is a by-product of the smelting of aluminum and zinc, and is extremely rare. A rare element is certainly not an advantage if we want to bring the energy production of GaAs solar cells to a TW level.

Besides that, the element Arsenic is poisonous. Not quite the ideal elements for a solar cells, which ideally would be abundant and non-toxic.

GaAs solar cells certainly have advantages as well. Efficiency is very good: lab tests have reach efficiencies of up to 26% under unconcentrated sunlight. Solar cells in commercial production reach as high as 20%.

Advantages GaAs

- Thickness. Gallium Arsenide solar cells can be extremely thin. GaAs cells already absorb sunlight when it’s made of a few microns thick. If you compare this with crystalline solar cells, that need at least 50-100 microns, GaAs solar cells need only few material, which brings the costs down.

- Band gap. The GaAs band gap is very near to the ideal for a single-junction solar cells: 1.43 eV.

- Heat insensitivity. GaAs solar cells are relatively insensitive to heat, which makes it more suitable for CPV, as concentrating sunlight involves higher temperatures. The insensitivity to heat is a major advantage compared to Silicon, which is quickly affected by high temperatures.

The major barrier of GaAs solar cells is currently the high costs, which makes it at the moment only suitable for CPV applications.