IEC63209 and its role in determining how long do PV solar panels last

Traditionally solar PV projects globally have asset lifetimes of 25 years. Some assets are even exploring longer lifetimes. In turn, PV module suppliers provide 25, 30, or even 40 year product lifetime warranties. This article explores the limits of the IEC 61215 certificate with regard to lifetime prediction, the term “bathtub curve” and accelerated lifetime testing like that of IEC63209. Above all, how the mentioned topics tie into giving some insight into module lifetimes.

What is the Bathtub Curve?

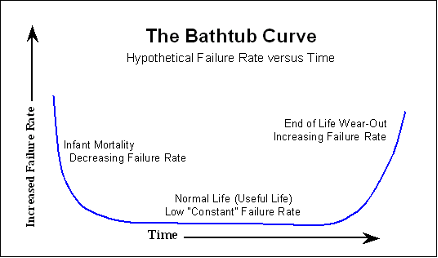

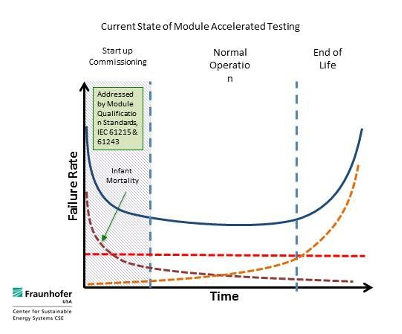

The bathtub curve as seen in Figure 1 is a graphical representation of expected failure rates in any power plant. It is broken down into three parts: infant mortality period - which typically sees a high rate of failure in a short time. Normal life period - where the number of failures remains constant. Lastly, the end of life where the failures start to once again increase exponentially.

Figure 1.The Bathtub Curve

Figure 1.The Bathtub Curve

Roughly speaking, when translating this curve to solar power plants the infant mortality phase is the first 5 - 10 years, normal life the following 5 - 15, and end of life the last 15 - 25 years.

IEC61215 and infant mortality phase

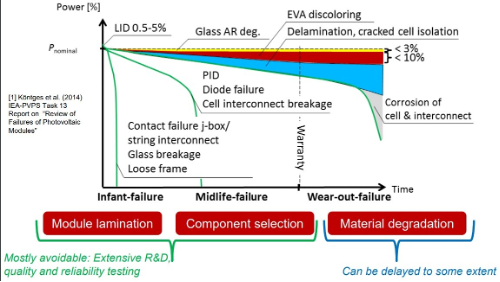

The function of the IEC61215 is to catalogue the faults as seen in Figure 2 of the first 5 years of a typical project and replicate them in the lab. Herewith gives the project some certainty that the modules will not have a high failure rate in the first 5 - 10 years.

Figure 2.IEA PVPS PV Module Degradation and Failure Modes

Figure 2.IEA PVPS PV Module Degradation and Failure Modes

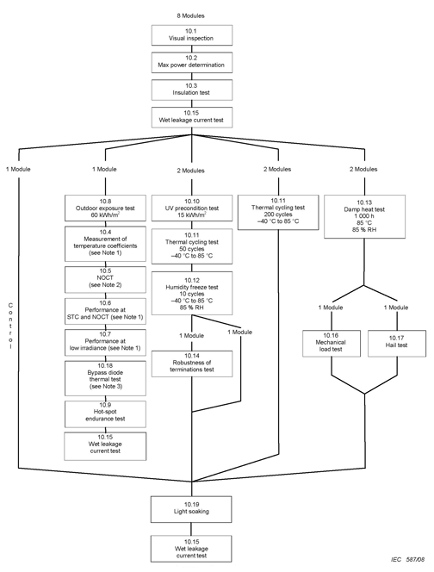

In a nutshell, the silicon PV module test IEC61215 is developed to gain some insight into the quality of the PV module. Conducting performance, climate chamber, and destructive tests in order to replicate failure modes and their impact like that of hail storms, LID, and different (but temperate) climates. If these modules lose less than 5% of their initial performance they are certified. All commercial modules must be certified in order to gain market entry. Roughly 70% of modules pass these tests but often do struggle with the climate chamber tests.

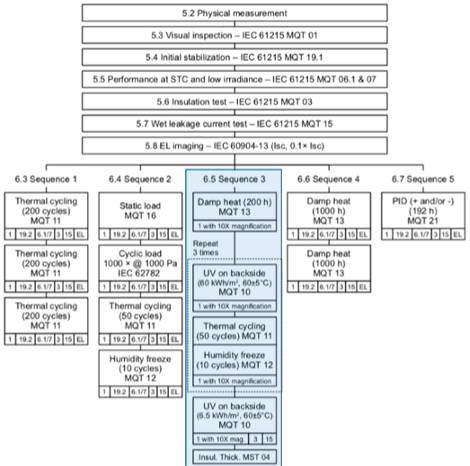

Figure 3. IEC61215 Test Method

Figure 3. IEC61215 Test Method

Fraunhofer USA corroborates this understanding of the function of the IEC61215 as seen in Figure 3. Considering that there is a risk that the panel produced at a workshop may deviate from the certified bill of materials; it can bring operational risk to its potential performance in the initial phase of commissioning. This is why parties like Sinovoltaics seek to provide zero-risk services by conducting factory audits and/or production monitoring to mitigate unnecessary failure rates in the first years of operation.

Figure 4. Fraunhofer USA IEC61215 Infant Mortality Coverage

Figure 4. Fraunhofer USA IEC61215 Infant Mortality Coverage

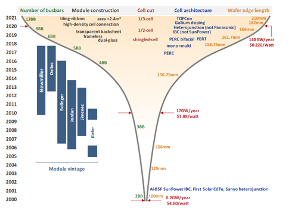

Limitation of infant mortality testing/IEC61215 and technological innovations

Do note that the last years have seen great leaps in module technology innovations, like that of the shift to half-cut, shingled, and larger cell sizes. This is represented in Figure 5 known as the martini graph by NREL. This means that a buyer of PV modules should note that the new failure modes and degradation rates may arise and in turn, will need to be integrated and tested for in the next reiteration of the IEC61215. This is a typical cycle of 3 - 5 years. The certification is often lagging behind technological advancements. This is one of the limits of the IEC61215 certificate with regard to lifetime prediction, even for the infant mortality phase.

Figure 5. Martini Graph of Technologies by NREL

Figure 5. Martini Graph of Technologies by NREL

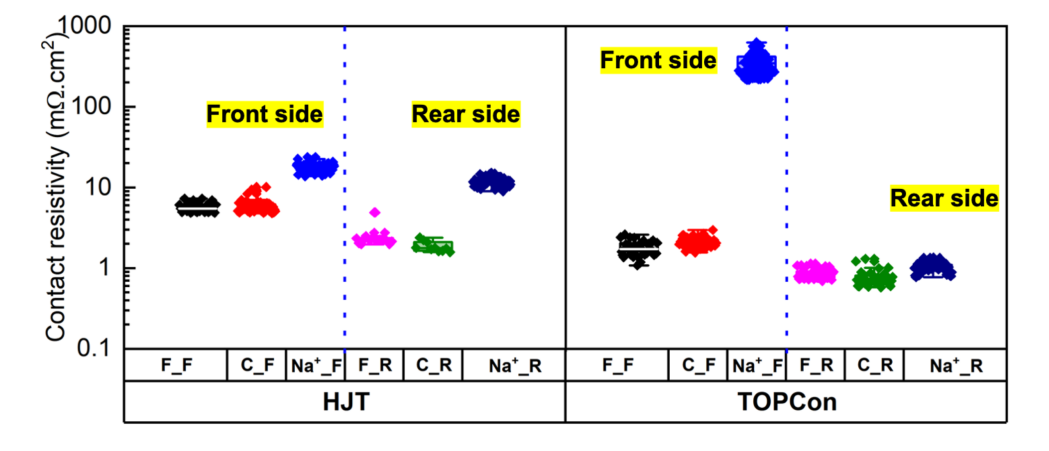

Exemplary hereof is the recent work by the UNSW SPREE team, which is lead by Dr. Bram Hoex on vulnerabilities in TOPCON modules not yet considered in these IEC tests or tested for. Moreover, a high frequency of mass-produced modules when tested again for climate chamber tests, like that of thermal cycling fail (exceed the 5% degradation rate).

Accelerated Lifetime testing (ALT) and the birth of IEC62309

In order to gain some perspective on normal life (reliability) and end-of-life (durability) performance various ways of approaches for photovoltaic module accelerated testing have been developed. Initially, this was tackled by doing three times IEC climate chamber tests, like that of damp heat (3 x 1000 hours of uninterrupted cycle of 85 C temperature and 85% relative humidity), thermal cycling (100 hours of fast cycling between 85 C and - 40 C) and/or humidity freeze (subjecting the modules to cycles of 85 C and -40C at 85% relative humidity). Determining if it passed or failed if the module has not lost more than 5% of its initial performance. These tests were typically done in-house by Solar PV panel suppliers that have a lab.

Testing solar panels

Third-party commercial tests grew from this like that of the 25+ years by Atlas Weathering Testing solutions (climate chamber supplier), DuPont Module Accelerated Sequential Testing (MAST), RETC Extended Reliability Test Report, NREL PVQAT testing, PV Evolution Labs Reliability Scorecard (PV module reliability scorecard) and certifying bodies (like TUV Rheinland) having their own test methodologies. Each with its own variation and style of conducting these tests.

In order to standardize this method, the International Electrical Committee (IEC) developed alongside many of these parties the IEC63209. It was constructed as a test method and not a certification system.

Figure 6. IEC63209 Test Methodology

Figure 6. IEC63209 Test Methodology

In comparison with the IEC61215 scheme, as seen in Figure 4, the procedure of IEC63209 as seen in Figure 6 has a far greater amount of climate chamber tests (damp heat, thermal cycling, and humidity freeze). Moreover, it incorporates potential induced degradation (PID) testing and EL imaging.

Solar module testing and reliability certification limitation of IEC63209 or ALT testing

Albeit that the IEC63209 gives a good insight into the mid-life and end of life performance there are limitations to the test procedure. Like that of the IEC61215, it only can replicate known failure modes. Even then, some known failure modes are not accurately addressed like that of long-term ultraviolet (UV) exposure (ie: UVID in SHJ/TOPCON).

In addition, IEC63209 only to a certain extent incorporates different climates, focusing largely on temperate climates. Thus making it challenging to corroborate how these same tested modules will function in hot & humid or desert climates. Namely, as seen by research done by NREL, solar panels in these climates often have higher degradation rates and earlier failure events. More importantly, paraphrasing Peter Hacke from NREL, ALT tests are like an egg. Testing at 35 C gets you a chick and at 100 C a boiled egg - be careful to make assumptions on these test results. Particularly because solar panels are often exposed to stresses simultaneously rather than segmented into different singular events.

Conclusion

IEC61215 is to gain insight into the quality or first years of operation. IEC63209 into the reliability (mid-life) and durability (end-of-life) of the solar panel. It is not a guarantee of top performance but does mitigate to a large extent a wide range of known failure modes. New technologies may exhibit newer failure modes which will be accounted for in future versions of these tests. It's a game of catch-up.

As noted in Figure 5 many technological advancements are being made. Sinovoltaics as an independent QAQC inspection party is often in the production halls and aware of the latest technological advancements. Providing various in-house pass-fail criteria to tackle known failure modes to assist its client base in reducing risk.

Having underlined the importance of how the IEC61215 tackles infant mortality in the first years of operation and how deviating there from can undermine operational excellence; Sinovoltaics provides various services for factory audits and production monitoring to mitigate these risks. Providing in turn a zero risk project.

For independent power producers or long-term investors keen to avoid high failure rates during the mid-life and end-of-life, Sinovoltaics has partnered with labs to conduct IEC61215 and IEC63209 testing.