Nano coatings have been extensively used on glass, and the advantages are well known. A coating can make glass Hydrophobic & Dust Repellant and therefore makes it easier to clean the glass.

For that reason it doesn’t come as a big surprise that special coatings for PV modules have been developed recently. But are these coatings really worth it and does a 8nm coating really increase efficiency like some suppliers claim?

For all weather conditions ?

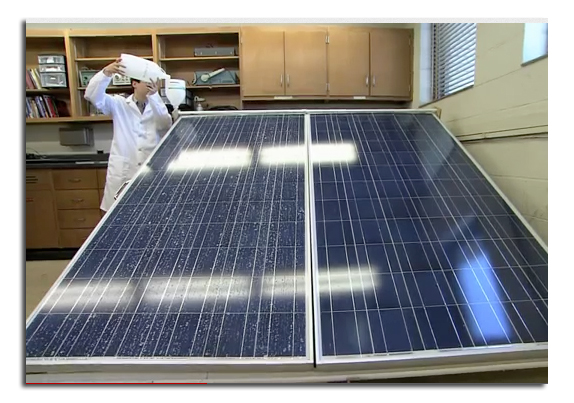

Under most weather circumstances, PV modules only need cleaning a couple of times per year. However in some countries, the conditions are different and panels get dirty much quicker.

For instance here in Shanghai people usually wash their car twice a week! Rain with pollution leaves a lot of dirt. Just like the cars, PV modules will need cleaning regularly and this is where the application of Nano coatings may be handy.

Circumstances where a Nano coating can be useful:

- Lots of rain

- Dust or sand

- Pollution

University of Houston’s Institute for NanoEnergy

Pros and cons

Let’s have a closer look at the advantages that manufacturers claim to offer – there are so many that they can’t possibly all be true.. – and a brief overview of what’s available on the market.

Advantages

The three main advantages of Nano coatings for solar panels are the following:

Hydrophobic

One of the advantages that counts for PV modules installed in rainy climates are the hydrophobic properties. This causes water to repel more quickly than uncoated “self-cleaning glass”, which is typically offered by PV manufacturers. This hydrophobic coating helps panels to let water flow off more easily and therefore would make the solar panel more efficient during inclement weather.

That’s an interesting claim, and it makes you wonder how much direct sunlight shines on a PV module anyway during heavy rain?

Without Nano Coating |  With Nano Coating |

Self-cleaning properties

The coating’s self-cleaning effect stops dust and bird poo from sticking to PV panels. With the help of the coating, all dirt will be easily removed after a little bit of rain or after manually spraying water on the panels.

This would help the panels to stay clean, maintain their efficiency and ensure that the maximum amount of electricity is produced. You would still need to ‘water your PV modules’ regularly to remove the dirt, in case you’re living in a warm climate without much rain.

Maintenance

Climbing on a roof to clean pv modules may be dangerous. Hiring someone else to do it, can be costly. If you can limit maintenance by simply spraying some water on the roof, and let the Nano coating do the rest, it sounds like a good alternative.

Solar panel Cleaning

Disadvantages

Increased efficiency?

Applying an extra coating on top of the surface of a clean PV module will not necessarily increase the efficiency. In fact, an extra coating will most likely reduce the transmissivity of sunlight.

It’s important to understand that efficiency is only gained, when the reduced light transmission caused by dirt is removed with the help of the coating. You will still need to wash off the pv modules regularly to keep them clean.

DIY vs ready made

There are some manufacturers of PV modules that now apply the Nano coating already in their factory. In a market where 99% of the suppliers offer a similar product, we guess a Nano coating is a welcome differentiation for sales people in our industry.

However seen the low costs of the DIY Nano coatings, we wouldn’t actually recommend to pay more for solar panels that have the coating already on it. Also, we would be keen to see actual test results of these coatings, as we haven’t received any from the PV manufacturers that we asked.

Conclusion

Finally some claims from suppliers are hard to verify, such as

“… the coating pays for itself in under a year.”

“Nanocoating increases efficiency up to 30%”

Other suppliers claim that their coating “Is resistant to salty air”. Perhaps it is true, however this would only be an advantage when the coating is also applied on the corrosive parts of the PV module ie. the frame.

Besides that, PV modules that have passed the Salt Mist Corrosion Test are already sufficiently protected against salty air.

Based on our experience and on a few test that we performed ourselves, Sinovoltaics argues that Nano Coatings may be a good solution in areas where a lot of dust and dirt lands on the PV modules, and it will help to wash dust and dirt away with rainwater.

However, we are less convinced that the hydrophobic effect of Nano Coatings will help to remove rainwater quicker from the solar panels and therefore would increase efficiency of the PV module. Perhaps future testing data will change our opinion on this.

Major Nano Coating Companies:

Companies that develop Nano Coatings for solar panels:

Nanopool | Nanopool ® GmbH is an innovative family business located in Germany. Since 2001 its main activity is in the surface refinement field and recently it developed a Nano Coating for pv modules. Visit company website here. |

Nanoshell | NanoShell ltd is a UK owned company with the ability to deliver cutting edge nano coatings and impregnators to clients in any part of the world. The company has developed a Nano Coating that can be applied by end users. Visit their website section on pv here. |

P2i | P2i specializes in invisible surface functionality and has developed a Nano Coating for pv modules. Visit their website here. |

Nanoclear | Nanoclear is involved in the manufacturing and supplying of a broad array of Nano Clear Treatment – Nano Clear Protective Coatings For Glass & Ceramics. Recently it has launched a coating specifically for pv modules. Visit their website here. |

| NanoSonic is a US based company and has developed HybridShield Solar, a coating that can provide higher efficiency, self-cleaning properties and enhanced performance to photovoltaic (PV) panels or concentrating solar power (CSP) mirrors. HybridShield Solar is a non-halogenated, low-VOC, spray-on or brush-on coating that is non-toxic at every stage of development. Visit company website here. |

Jessie Angelaere

on 25 Jun 2015sudeep gupta

on 17 Jan 2017Waqar

on 17 Oct 2015Chaitanya Yardi, Director, NRG Technologists Pvt Ltd

on 08 Feb 2017