Webinar Summary: Autonomous Drone EL Mapping for PV Power Plants

This webinar, hosted by Sinovoltaics and Quantified Energy Labs (Q E Labs), presented cutting-edge technology for on-site electroluminescence (EL) inspection of solar modules using autonomous drones. The session, led by Dr. Yan Wang (CEO of QE Labs) and Niclas Weimar (CTO of Sinovoltaics), showcased how automated EL imaging can transform post-installation quality control and maintenance of large-scale PV plants.

1. The Need for Field-Level EL Inspections

While EL imaging has long been standard at factories, field inspection remains limited. Many PV systems suffer hidden degradation and cell-level defects that only EL imaging can reveal. Traditional manual or sampling-based inspections are slow, labor-intensive, and incomplete, leaving asset owners exposed to undetected microcracks, solder faults, and other issues that reduce energy yield and long-term ROI.

2. QE Labs’ Autonomous Drone EL Mapping Solution

Q E Labs developed an AI-enabled, autonomous drone EL mapping system that integrates:

• Customized drone and camera hardware for high-resolution nighttime imaging.

• Automated flight control via a mobile app – minimal pilot input required.

• AI-powered analytics to detect cracks, dark cells, soldering faults, and estimate power loss.

• Digital twin visualization to geolocate and display defective modules in a dashboard interface.

The system can inspect up to 15,000 modules per 8-hour night shift, achieving one module per second throughput. Over one million modules have already been analyzed worldwide.

3. Use Cases and Applications

Drone-based EL mapping is used throughout a PV project’s lifecycle:

• Pre- and post-installation testing (COD and early O&M baseline data).

• Degradation monitoring and preventive maintenance during operation.

• Warranty and insurance claims, including natural disaster assessments (hail, typhoons, sandstorms).

• Performance loss investigations and root-cause analysis.

• Repowering and end-of-warranty inspections for aging assets.

The technology enables faster identification of damaged or underperforming modules, allowing for targeted replacement and data-driven maintenance.

4. Case Studies and Results

• 200 MW project in Australia: full-site inspection completed within a week using multiple drones.

• 60 MW floating PV plant in Singapore: successful large-scale deployment on dynamic surfaces.

• Post-hailstorm inspection: AI quantified cell-level damage for insurance replacement eligibility.

• Warranty case analysis: correlation between EL-derived “uniformity scores” and lab-measured power loss enabled predictive modeling of degradation.

5. Technical Highlights

• Uses InGaAs cameras for optimal EL sensitivity (1,150 nm range).

• Operates safely at night under low-light conditions (even full moon).

• Compatible with string inverters and combiner boxes via portable DC power supplies.

• Meets emerging IEC 62446-4 standard for on-site EL testing

• Future integration with factory EL data via barcode mapping to connect “Day 0” and “Day X” quality histories.

6. Key Takeaways

• Drone EL mapping provides comprehensive, non-destructive, and scalable inspection for any PV site size.

• AI analysis enables quantitative assessment of defects and power loss prediction.

• Regular EL inspections can prevent major financial losses by detecting degradation early.

• The technology fills the critical gap between factory QC and long-term O&M.

• Partnerships and field availability now span Asia, Europe, Australia, and the US.

Conclusion:

Autonomous drone EL mapping represents the next evolution in solar asset management—combining AI, imaging, and automation to deliver full-scale quality assurance across the entire PV lifecycle. This technology empowers developers, EPCs, and investors to safeguard their assets, optimize performance, and make informed warranty or insurance decisions.

[00:00:00] autonomous drone EL mapping solution which is a blend of innovative Hardware

[00:00:06] the Drone the camera and also a special software that to dedicated for maximize

[00:00:13] the EL inspection throughput and so far we have conducted EL measured over one

[00:00:19] million piece of panel and this number is Rising quickly and these are used

[00:00:24] to mainly derisk the effects on return of investment due to over degradation of PV

[00:00:31] recently the scale and the magnitude and also the frequency

[00:00:39] of no dusters is getting um getting severe and for example this video I just

[00:00:46] received yesterday it was show it it showed a super large solar farm get hail

[00:00:51] storm damaged

[00:01:00] hello and good morning and good afternoon and even good evening welcome everyone to this new

[00:01:08] Sinovoltaics webinar about the very exciting topic of onsite e testing at PV

[00:01:15] power plants I'm actually very excited to see that we have more than 300

[00:01:21] subscribers for today's webinar from more than 50 jurisdictions across this

[00:01:26] planet so we have participants from Chile um from Singapore India Saudi

[00:01:35] Arabia Poland Austria Qatar Malaysia the

[00:01:41] Bahamas Finland Algeria and many more

[00:01:46] for today's webinar like usual

[00:01:52] we aim to keep it within 1 hour with

[00:01:58] about 35 to 40 minutes of presentations and then 50 minutes of

[00:02:04] Q&A at the end and we highly encourage you to participate in the Q&A and ask

[00:02:11] any questions that you may have and there's no bad questions you can type your question

[00:02:18] here in the chat box and we see those questions and then we will try to answer as many of them as possible

[00:02:26] now let me introduce you to our

[00:02:31] guest speaker today which is Dr. Yan Wang co-founder and CEO of partner QE Labs in Singapore

[00:02:39] Yan has more than 15 years of experience in the Solar PV industry

[00:02:45] under his belt and before setting up QE Labs he was in charge of the PV module

[00:02:51] cluster at the very famous Series in Singapore and he was also a research

[00:02:56] fellow at the National University of Singapore, I'm personally very happy that

[00:03:01] Yan could make it today to join us for this month's edition of our webinar Series so Yan a very welcome to you

[00:03:11] thank you Nicholas then a bit about myself my

[00:03:18] name is Niclas Weimer, I'm today's host and I will also do a brief

[00:03:24] introductory presentation about onsite El Imaging at PV power plant

[00:03:30] I am one of the founders of Sinovoltaics and currently acting as the CTO I'm based out of Hong Kong and for

[00:03:39] those that are joining us here for the first time allow me to quickly explain what Sinovoltaics does

[00:03:47] SO Sinovoltaics specialize in technical risk management of solar PV and battery energy storage equipment,

[00:03:52] we are best known for performing factory audits, quality inspections of PV and BESS equipment

[00:04:01] destined for power plants all over the world as well as for ESG and

[00:04:06] traceability services at the factories in the Asia-pacific region and these are delivered by a

[00:04:13] team of PV and BSS technology specialized and accredited Auditors and

[00:04:18] quality Engineers all based near the PV and yeah BESS factories here in East

[00:04:26] and Southeast Asia, India turkey and now also North

[00:04:34] America, now with without further ado yeah let us pier straight into

[00:04:41] the modules of a PV power plant via EL Imaging and I will start first with a

[00:04:46] brief background and also methodologies of small scale EL Imaging at PV power

[00:04:53] plants before Yan will expand on mass scale applications and methodologies

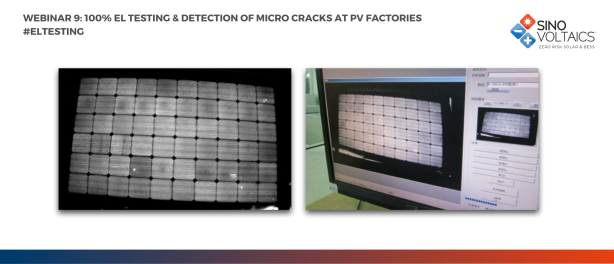

[00:05:03] so to start with how does onsite or can

[00:05:09] also call it in situ EL Imaging at the power plant align with EL Imaging at the

[00:05:15] factories in the PV project cycle now it's only been like

[00:05:21] roughly 10 years that EL imaging has somehow or somewhat increasingly become

[00:05:26] a standard or let's say a pretty common Quality Control item during mass

[00:05:32] production of PV modules at almost any module assembly line which is unlike in

[00:05:38] the early earlier days even when at the factories, the focus was more on

[00:05:44] visual inspection and IV measurement and some electrical safety checks here and there only so that also meant that there

[00:05:54] are not or if at all only Limited EL image data sets available or many if

[00:06:00] not most of the early PV power plants that were

[00:06:06] constructed and while EL Imaging is nowadays a

[00:06:11] Cornerstone of proper quality control allowing us to peer inside the cell

[00:06:19] and identify potential quality issues such as micro cracks and cell

[00:06:25] breakages and loose solders that can impair the performance of a module and

[00:06:31] also despite EL Imaging Technologies having enormously improved still there

[00:06:37] are many projects here and there when there's no thorough EL Imaging

[00:06:42] performed or where there's no data set acquired being kept so this brings us actually to the

[00:06:52] topic of why we do onsite EL Imaging, now common examples of

[00:06:59] applications for Onsite EL Imaging at power plants include so for existing

[00:07:06] plants maintenance and degradation testing, troubleshooting so troubleshooting

[00:07:12] testing when some issues have been identified and basically operators

[00:07:18] want to find out what exactly they are and also quite a common and I

[00:07:26] would say major application is for acquisitions of existing power

[00:07:31] plants including repowering projects and then you have also newly built power

[00:07:38] plants and for these cases like EL Imaging can for example be part of a

[00:07:45] commissioning testing program or for the purpose of having a full set of

[00:07:51] module data including from pre- shipment to post shipment either directly or

[00:07:57] after so directly after container unloading or after installation and such comprehensive

[00:08:07] FAT and SAT phase testing so combined testing basically can come in

[00:08:14] come in handy basically in the event of quality disputes and it helps to narrow down the origin of quality

[00:08:23] issues, now how is such onsite EL Imaging

[00:08:28] actually carried out and this brings us also to the topic of today's

[00:08:33] webinar, it very much depends on your testing setup in scope basically

[00:08:40] whether it's just a few pallets of modules fresh from the container an existing small rooftop installation of a

[00:08:46] few or dozen dozens of kilowatts or ground mounted utility scale 300

[00:08:53] megawatt power plant so it used to be in the earlier days that people would

[00:08:59] walk into a power plant and doing here and there some visual checks connection checks, thermal imaging with a

[00:09:06] portable device and then with the increasing popularity of EL Imaging as

[00:09:12] a reliable quality control item so to see what's going on the cell level the first portable EL testing kits also

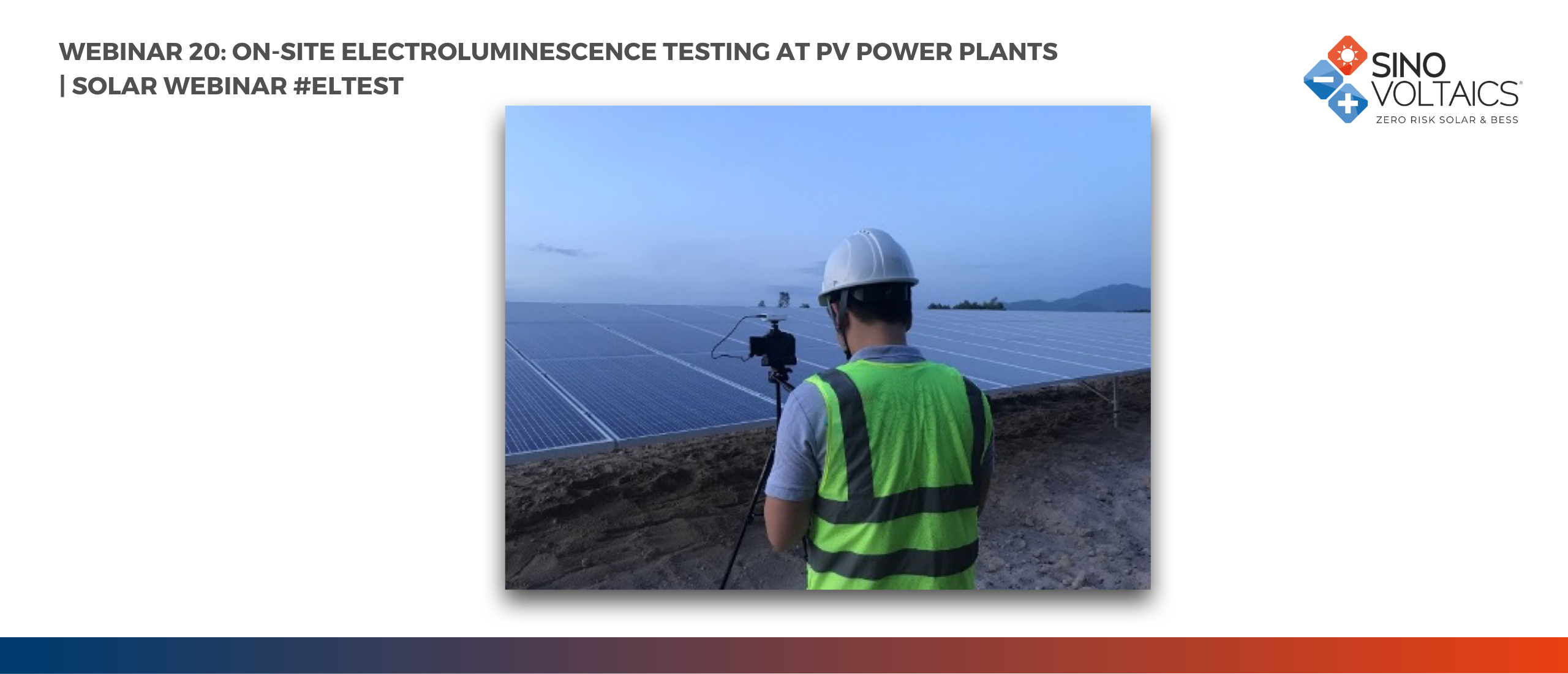

[00:09:18] came out, so how does

[00:09:23] small scale EL Imaging with such

[00:09:29] class I would say portable kits work so if you after pre-planning of the

[00:09:36] testing scope of work so you figured out your plant and the basically workload that need

[00:09:44] to be done hen

[00:09:50] basically make sure that there is sufficient external power sources to

[00:09:56] power the testing equipment, having also sufficient support on site for the disconnection

[00:10:04] and connection of modules or string of modules and equipment and then the

[00:10:10] testing work could essentially start, testing

[00:10:17] Outdoors would generally be performed um during

[00:10:23] nighttime and for for single basically

[00:10:30] so for single not installed modules from pallets this would normally be done in an for example in

[00:10:37] building nearby and then they would be covered by a by black cloth the portable EL testing kits

[00:10:45] generally consist of following items so you put it here on the slide it's a

[00:10:50] portable EL camera itself then also a tripod you can also see that here on

[00:10:56] the on the image and so to basically ensure that the image quality is you

[00:11:03] know that you don't have blurry images and also a DC power supply unit

[00:11:10] either for single modules or even for whole strings of modules so to feed basic current back

[00:11:16] to the modules at night and these power supply units normally they would be powered by of course an external

[00:11:22] power source which can be in form for example of a diesel generator now when measuring install PV

[00:11:29] modules and depending on the Tilt and angle of the installed modules addition

[00:11:35] equipment such as in form of a platform to capture the modules from

[00:11:41] a more yeah perpendicular angle or modules in in the upper string basically

[00:11:48] can be used in the event you use such portable y testing kits then

[00:11:54] when you move from one module to another or from one string to another the respective module or string has to be

[00:12:00] disconnected and then reconnected and the new ones have to be reconnected so

[00:12:05] you can you can already see this is quite a tedious

[00:12:11] process now here can also see some examples of EL images captured with such

[00:12:19] such a portable equipment, actually this one naturally

[00:12:27] with such a small portable EL testers the possible scope of testing has

[00:12:33] also been quite limited so unless you employ a large team with multiple El testers so that you can

[00:12:39] measure massive quantities of modules in a utility scale power plant and

[00:12:47] basically with EL Imaging speeds of could say 200 to 300 modes per equipment

[00:12:54] and team per night it would end up being too

[00:12:59] prohibitive to approach such large scale or mass scale projects with these

[00:13:05] portable kits, therefore the usage of the portable EL kits that you have just

[00:13:12] seen in the previous slide is usually confined to small scale testing scopes for example for small installations or

[00:13:19] measurement of Select quantity of samples or post arrival checks of sample

[00:13:25] pallets and here so that's now the intended slide

[00:13:31] for what I want to mention here is there's also some examples from Sinovoltaics

[00:13:37] PV plant inspection work that shows what testing using such portable EL kits

[00:13:42] can look like, obviously with the earlier mentioned

[00:13:51] lack of comprehensive EL

[00:13:57] quality data there's also a strong inclination to carry out Mass Scale

[00:14:03] EL Imaging so it means basically

[00:14:09] like it's done basically at the factory level right where you have multiple basically almost all

[00:14:18] assembly lines basically carrying out EL testing on all on all the modules and

[00:14:25] this is especially crucial when the plant is being Acquired and there's lack of quality data for that

[00:14:32] plant so with the arrival of and we the mass Market commercialization of

[00:14:37] drones for example thermal imaging has become quickly one of the most common test items that you can see

[00:14:43] nowadays in utility scale power plants it is a relatively fast and cost

[00:14:50] efficient method and provides for a general macro overview of what

[00:14:56] is going on in the plant so you yeah potentially miss out

[00:15:02] on quite some defects that are not of course visible via infrared thermography

[00:15:08] so the NR of inherent cell level issues can best only be identified with

[00:15:15] real Imaging, it is therefore no surprise that

[00:15:21 in the recent years work has been done to enable mass scale EL

[00:15:28] Imaging with drones flying over your plant and being able to capture EL

[00:15:33] data thousands of modules in a single measurement exercise on the simple

[00:15:39] night as possible and with this I would like to pass the microphone to

[00:15:47] Dr. Yan Wang from QE Labs, Yan please continue

[00:15:53] Thanks Niclas, a nice overview about the EL technology so let me share from my

[00:16:07] laptop

[00:16:37] good morning to everyone who attend this webinar, I'm today give you an

[00:16:43] overview about the autonomous Drone EL mapping technology that had developed by

[00:16:49] Quantified Energy Labs, we firmly believe this is a no bringer choice for

[00:16:55] for the solar assets owners, Quantified Energy Labs was

[00:17:00] founded by a group of senior research fellows from the Solar Energy Research

[00:17:05] Institute of Singapore, myself I'm WANG Yan, I'm the CEO of the company that

[00:17:10] driven the application of the Drone EL and a lot of work has been completed

[00:17:17] by my colleagues, my our COO Yong Sheng, who was the research group head for new

[00:17:25] solar mod Technologies and the main inventor for the Drone EL is Dr. Karl Georg BEDRICH, he's our CTO

[00:17:34] and he has focused on the EL technology for more than a decade and we have Mr CHAI Jing who sits in China at serving the

[00:17:42] domestic needs our diverse background has combined

[00:17:47] together and delivered the Innovation Technologies, so for Solar for a decades

[00:17:54] we know that a Solar industry we have a common issue which is over

[00:18:00] degradation for the solar system performance and based on a recent

[00:18:06] research publication from ENRO the National Lab from U.S., we see that they have the Statics

[00:18:15] data showing the performance loss rate distribution the meaning value is force

[00:18:21] unicely along with the LC calculation which is 0.75% per year but unfortunately

[00:18:30] there are a large portion of the system which is falls on the left side of the medium value that showed higher

[00:18:36] degradation of course this will be reduce your return of

[00:18:42] investment and there are so many reasons can causing this over liquidation for example in a proper right

[00:18:51] system design that you have shading on the on the array or in a proper the

[00:18:59] O&M activities that not timely remove the Dust for example of course there's

[00:19:05] equipment malfunction equipment is an is a big contribution to this over

[00:19:11] degradation as the main equipment that convert the sunlight into electricity

[00:19:16] the solar panel the PV module it's a major reason it's a major

[00:19:22] equipment that we must take a deep look into and according to the IA

[00:19:28] performance and reliability photovoltaic system research group in the task 13

[00:19:35] IEA PVPS it show that along the life of

[00:19:40] the solar panel there are quite a number of defects mechanisms that can

[00:19:47] reduce the performance of the solar panel and these defects must be timely

[00:19:53] identified and to just its performance which is potentially

[00:19:59] affect the overall system energy yield and must be timely replaced the Worster panel so this is why we

[00:20:07] need an inspection Tech inspection solution for the for the solar panel, so for many years that proactive

[00:20:15] PV module quality management has become a routine in our Solar PV industry, it

[00:20:21] start from pre-production and then every product should have IEC certificates and

[00:20:27] during the production there's a third parties to do the factory audit make sure that the product produced being

[00:20:34] produced in the recipe before the shipment all the panel

[00:20:40] panels should at least underground one time of the EL and IV test sometimes

[00:20:46] there's a sampling test to be happening in the third party lab until the container loaded for shipping

[00:20:54] this will be 100% of the module tested to exclude any defect panels from

[00:21:01] the delivery but then going to the field we see that the situation have been complete changed there's a random

[00:21:08] there's a sampling, sampling EL test after the module arrived but unfortunately there's a

[00:21:16] very few module have been tested in the post installation phase, for example

[00:21:22] we know that there random EL test may happen may be applied to verify the

[00:21:27] installation quality after PV module put it on the rack and the most common used

[00:21:35] technology for COD testing and commissioning is a string IV scan or the Drone sonography and the EL may be too

[00:21:43] chosen to verify the Cal abnor module only but then carry on to the 25 years

[00:21:51] O&M there are very random case that you will think about to use the EL and we see

[00:21:57] this is the gap in our industry and our colleagues from Sinovoltaics have done a

[00:22:05] a great job that cover the risk from the production to the to the shipment and at

[00:22:11] QE Labs we are focusing on the modules that being installed on the rack and

[00:22:19] we do focus on the field inspections, EL is the golden

[00:22:27] standard quality control testing for our industry, you can see that this

[00:22:33] equipment for inline EL is almost standard way that to do to check

[00:22:40] the internal defects of PV module but then if you look at the current

[00:22:46] technology for the field PV module testing as summarized by Niclas in his

[00:22:52] presentation so if you extended use the EL then most of the time it's a

[00:22:58] manual inspection which is too slow and inefficient for large

[00:23:05] scale solar farm inspection and there are automatic solution available for

[00:23:10] example using the Drone sonography but this is also sometimes inaccurate

[00:23:17] because the Drone sonography doesn't reflect all the internal defects so as a result

[00:23:22] insufficient quality control in the solar farm sometimes resulting in a big Financial loss so address this Challenge

[00:23:30] and at QE Labs we have developed this Innovative autonomous drone EL mapping

[00:23:37] solution which is a blend of innovative Hardware the draw the camera and also a

[00:23:44] special software that to dedicate for maximize the EL inspection

[00:23:50] throughput and then it's supported by AI driven and conative Analysis

[00:23:57] algorithm for big data processing and all the data will be eventually hosted on a digital TN system

[00:24:04] that for date visualization to locate accurately locate the defect

[00:24:10] panels, so here I show some video about the actual work for example this this video is

[00:24:18] showing our onsite EL inspection with the Drone, one colleague sitting here

[00:24:25] to do the DC current switching he has an external DC unit when the current in

[00:24:31] the modules are becoming LED and image light the second gentleman is the pilot

[00:24:38] he is control the draw and flying from one side to the other side of the string

[00:24:44] and do a continually continuously scanning so when he complete

[00:24:50] inspection of the one string and then the technician just switch

[00:24:57] the DC to the next according to the testing plan and then our pilot just repeat the scanning

[00:25:04] process until end of this string so assuming that each of the string composed of certain modules and this

[00:25:12] video is about 17 seconds and the roughly speed is about one module

[00:25:19] per second so it's rather very it's a very fast inspection so our highest

[00:25:26] inspection throughput is so far is 15,000 modules per eight hours night

[00:25:33] shift so the reason we can achieve this high repute because the team has

[00:25:39] developed this special app as you can see here it's running on

[00:25:45] an Android phone on the left is the field of view that the camera can the

[00:25:51] Drone can see it's a one string of the module and the Drone is flying from home

[00:25:56] position just now to the start point of a string that to be tested so before the testing we need input of the system

[00:26:04] layout as the base map so during the scanning you see that the Drone is continue it's an EL video most importantly

[00:26:11] our pilot doesn't control the Drone so you see his fingers is not on the joystick the Drone is flying by itself

[00:26:19] this means that with a basic training anyone can easily use this app

[00:26:25] associated with our special Hardware that can carry on the inspection so this

[00:26:30] is also guarantee the ended quality control for the results we can

[00:26:37] captured with the Drone so for more old details you can referring to my colleague presentation at the PV

[00:26:44] Reliability Workshop in 2021, so the third step is processing the

[00:26:50] large amount of data captured from the field and we use the AI for

[00:26:56] feature detection to ping pong the location of the defect

[00:27:02] such as crack or duck cells and we also run the quantum analysis algorithm to

[00:27:07] estimate the power loss of the module the last step is the date visualization so

[00:27:13] I suggest I strongly recommend if you have time you are interested

[00:27:18] please feel free to go to our website which is dashboard.QElabs.com and to

[00:27:26] register a demo user so that you can experience the power of EL

[00:27:33] inspection, so I show some equipment we have so here is coming from comes the

[00:27:40] the first generation drone EL Equipment we have that is released in

[00:27:46] May 2022 at Intersolar so this is a customized drone and an in-house

[00:27:54] developed camera that attached to the Drone St Gimbo and we have a DC power supply with the switch

[00:28:02] boxes and this drone is serving has done a great job for us is our

[00:28:09] working house now we are going to release the second generation in the in solar this year it's becoming a

[00:28:16] all-in-one drone inspection and here is our booth at C4.553 if you are

[00:28:23] interested please come to our booth during the Intersolar so some details

[00:28:28] about the current injection because this is sometimes the first question come to

[00:28:34] us there's a there's an argument that how to disconnect the cables from

[00:28:42] the string water or do the cabling for current injection is it's a lot of

[00:28:48] Labor work and complicated but based on our experience this can be really a

[00:28:54] fast process for example here showing that we are using DC power supply

[00:29:00] from a manufacturer in Netherland the input is a three-phase

[00:29:06] power that normally we rent it a diesel generator with a vehicle that bring

[00:29:11] bring it along the main road from Station to Station and the output of

[00:29:17] this DC unit is up to 10 net at 1,500 volt for one strain inspection so

[00:29:25] normally we set the current injection into ATM which is close to 80% of the IC

[00:29:31] and doesn't affect anything to the model during the inspection so this will be sent to

[00:29:39] the to the site if the system installed a string

[00:29:45] combiner box like this so what we what we are doing is we use two clamps as

[00:29:51] the output from the DC and then use it clamp to the D to the to the DC bus bar

[00:29:58] the string bus bar in this in the combiner box so and then next we just

[00:30:04] pull out all the fuses and then push one back to form a connection of this string

[00:30:11] from the DC power supply for the testing once it's done we turn off the DC pull out the fuse push the next one

[00:30:19] and turn on the equipment and then just repeat so this is very efficient way for the

[00:30:25] inspection another setup if the system I installed the string

[00:30:30] inverters like this so what we need to do is to pull out all the string mc4

[00:30:36] connectors and connect it with a special cable that to our switch equipment and

[00:30:43] this switch equipment can automatically do the switching from channel one to channel 20 and then the Drone just need

[00:30:51] to continue flying and without any Landing during

[00:30:59] the inspection so we normally send two sets of the equipment one switch box

[00:31:06] to be used for this string in water while the other group

[00:31:13] use another set another equipment to set up the next one so this can continue

[00:31:18] or similarly continue the whole inspection, we have conducted a

[00:31:23] service since 2022 after the Covid restricted lifted and some notable

[00:31:32] projects including 60 megawatt sorry 60 megawatt floating PV in Singapore

[00:31:38] we have done this for sop and has been acknowledged in their press release and

[00:31:45] we also have conducted 200 megawatt solar farm inspector in Australia and

[00:31:51] featured in the PV magazine website and this super large utility scale

[00:31:58] solar farm experience have demonstrated the technology is mature for dealing with

[00:32:03] big projects and so far we have conducted EL measured over one million piece of panel

[00:32:10] and this number is Rising quickly and these are used to mainly de-risk the

[00:32:16] effects on return of investment due to over degradation of PV panels, this the Drone EL technology was

[00:32:25] instrumentally important for the critical Milestone inspections for

[00:32:31] example this is for for the day Zero COD inspection or before the EPC

[00:32:37] warranty expiring what call DLP or in the earlier phase of the time around

[00:32:43] year five when you do the considered preventive and corrective maintenance if there's a over

[00:32:50] degradation and suspect the mod degradation over degradation is the reason and or we

[00:32:55] have sometimes respond to the post major events like the neutral disaster or

[00:33:00] supporting the AET transaction to do the due diligence and the lastly before

[00:33:06] the product warranty expiring we can do the revamping and repairing of the

[00:33:12] system so these are the five classic use cases for the Drone EL technology and in

[00:33:18] today's presentation I'm sharing our case studies for the pre COD warranty claim and insurance

[00:33:23] claims, recently the the scale and

[00:33:29] the magnitude and also the the frequency of dusters as getting

[00:33:36] getting severe and for example this video I just received yesterday it

[00:33:41] was show it showed a super large solar farm get hail storm damaged

[00:33:47] this is was this was happening just last week another time other times we are

[00:33:54] also dealing strong winds like Sandstorm in the in the desert or typhoon or tornado

[00:34:00] and you can see from this video that the module are completely broken so these

[00:34:05] other natural disasters are happening right now as the highest risk to the

[00:34:11] Solar investment so the question is how we dealing with the situation how to

[00:34:18] judge the surviving modules quality so here I show the case study and in

[00:34:26] this in this small project we do the visual Imaging and only found few

[00:34:31] modules have the shattered glass but if we do the EL mapping is size this shattered glass we saw that some of the

[00:34:38] modules have show a Dark Cells when we continue zooming this is the classic level details of our EL image captured by

[00:34:45] the Drone you can see that there are cracks inside the module and

[00:34:52] these features are nicely captured by our AI so the next after in after

[00:34:58] inspection we are do the counting of how many solar cells inside the panel have

[00:35:04] this defects and can adjust this number according to the insurance policy

[00:35:12] threshold number for and then we can draw the distribution for example in this particular project the magic number

[00:35:19] is three cells and if there's a if there are three solar cells have more as

[00:35:26] cracks and then the insurance company will be give you a

[00:35:31] replacement so this is how we help the asset owner to Counting how many modules can be claimed besides beyond

[00:35:40] the visual damage so we also use the technology for super large utility scale projects and

[00:35:47] we propose is three steps working for such a situation so it's starting from

[00:35:53] Counting of the visual damages and then the step two is to a sample EL image of the surviving modules according

[00:36:00] to the AQL tables then to determine whether the remaining module at the site

[00:36:05] can be continue operation and then the third step is after rebuild the system because

[00:36:12] either you buy the new modules to fill avoid to replace the damage damage

[00:36:18] module or you relocate of the old module to a Zone and then rebuild the

[00:36:24] system so you always need a full side or Mass EL inspection to justify whether

[00:36:30] the remaining panels are still in good condition and this is critical for

[00:36:36] to negotiate with the wonder that whether your old modules still valid for

[00:36:42] the warranty claim warranty coverage so this is our experience

[00:36:47] and we are working on a white paper to address this issue, the Second Use case is low

[00:36:55] performance investigation and warranty claims, so modules can be damaged by the external

[00:37:01] force that reduce your system performance it also can that have aging

[00:37:06] effect or some fault some defects that reduce the performance

[00:37:14] reduce output of that panel and this should be going to this category of

[00:37:19] warranty claim so we did one project like this we draw the EL map you can visually see that there are modules with

[00:37:26] duct cells and distributed across the the whole solar farm and the solar the

[00:37:33] panels if we zoom in we saw it looks like this there's lot of duck cells then the question is for warranty

[00:37:40] or warranty claim most of the time according to your Clause that power

[00:37:45] loss is the key number that to justify how much percent of the power has

[00:37:51] dropped compared to the name value, to support our clients and we did the here

[00:37:57] I share the case study to that we have correlated the EL image data analytics

[00:38:03] with the STC a testing test result in the lab and to estimate par loss of each

[00:38:10] panels installed on the side, so we Define the first step is that we defined a quantitive score based on the EL image

[00:38:19] that is called uniformity score and it's calculated based on the brightness

[00:38:24] or darkness and intensity deviation from this of the Solar cells across the module

[00:38:29] if the number is zero we know that it's the worst the panel that's completely dead if it's 100% is 100 that means the

[00:38:37] whole panel is in good condition then we got the scores for

[00:38:43] each panel and then we can draw the distribution like this of the whole modules installed on the site then the

[00:38:50] last step is we select samples from different score and send to a third party's lab to do a lab testing

[00:38:58] check how much percent of the power has been lost compared to name value what amazing is that we can

[00:39:05] correlate the EL score with a set power loss measurement and then probably

[00:39:10] from this case that we can see that either 20 or 25 below that probably this

[00:39:18] module have some issue and then we can use this correlation and come back

[00:39:25] to the statistics to filter out how many panels are having

[00:39:33] suspected have higher degradation and then use the dashboard I just need to filter

[00:39:41] according to the UNIF uniformity score and all the modules are below 20 and can

[00:39:48] be visualized on the map so that the O&M engineers now having a tool that to can

[00:39:54] locate the worst panels and can easily to do a replacement this is a very

[00:40:00] useful in case of low

[00:40:05] performance investigation so the use

[00:40:10] case three is a new system pre or DRP testing and we found this is more

[00:40:16] important because a clear Baseline a data set is essential to compare with

[00:40:23] the future in measurements either you in Insurance claim you need to

[00:40:29] prove that this feature are happening associated with that disaster or you

[00:40:35] have to show that this over degradation that caused by this manufacturing issue are really happening

[00:40:42] in day Zero so that's why we are suggesting to consider the IR as part of

[00:40:47] the testing for COD test right now is most commonly doing the IEC 62446

[00:40:56] IEC 62446 - 1 string IV, IEC 62446 - 3 drone IR the good news is IEC committee has

[00:41:02] recognized this need and working on a new series of Drone onsite EL which is IEC 62446 - 4

[00:41:08] of this series in IEC standards, so here I show the case studies three for one COD testing

[00:41:15] project we have done the EL map according to the fail and pass

[00:41:21] criteria we found so many modules has been failed and the the modules

[00:41:29] defect at this side is showing is looks like this a lot of cracks at the edge of

[00:41:34] the panel and we try to explain to understand why it happening and the

[00:41:41] distribution of of this defect panel on the map draw us attention it's

[00:41:47] showing that it's always like a line you see here the distributions like line so

[00:41:53] this is indicate might be this is causing by some someone walking on the

[00:41:58] panel he saw that walking on the edge of the panel and should be safe and so he

[00:42:04] just walking this direction but unfortunately this is not true it's already causing a lot of damage and this

[00:42:11] modules has must be replaced once you found this issue so

[00:42:19] this is for COD testing and then another case study is

[00:42:24] that recently UNSW researchers have announced a new defect feature

[00:42:32] like this module they call it inyang and actually we found this

[00:42:38] since a long time ago and we call the bright spot so far this is

[00:42:45] happening has this phenomenon has no scientific explanation to that but

[00:42:53] when we do the when we do the inspection

[00:42:58] we use this dashboard to filter out where are the locations of this kind of

[00:43:03] feature defect panels surprisingly it show that is clustered in a certain

[00:43:08] region of the of the module of the system and this suggesting that this

[00:43:14] kind of defect may be a manufacturing issue and from that batch of

[00:43:20] deliveries and this is the the use case for the for the EL Tech Mass

[00:43:25] so because you can now see a a small scale and now expanding to the whole

[00:43:31] side based on distribution we can justify we can explain what is happening for this side it triggers

[00:43:39] our Future Works plan because we need to verify that the module are

[00:43:46] really manufacturing issue and we need to see what happening from the factory and this triggered our Future Works

[00:43:54] we will connect the unsigned set test EL date EL map with the factory acceptant test EL

[00:44:01] database through the ID mapping of the as-built system every solar panel have

[00:44:07] this barcode in the front in the back and there are nowdays it's very

[00:44:14] popular to do a ID scan of the solar farms by end of the EPC phase and

[00:44:21] what we need to do is now we need we use this ID mapping to connect the

[00:44:27] two parties and now we can connect the factor data Day Zero at COD and day x in

[00:44:33] the future for example this module we saw that a busbar soldering issue

[00:44:40] eventually is turned into a severe substring mismatch that this sub stream

[00:44:45] just completely go we don't know whether this this soldering issue are coming

[00:44:51] from the factory if we have the ID mapping now next we can understand completely so this is the technique

[00:44:59] for next phase to form a holistic quality control package so here showing that the

[00:45:07] Drone EL nowadays is available with our partners in the countries in the in marketing grain for example us Europe

[00:45:14] China,Southeast Asia and Australia and now we are running a road show for Malaysia, South Korea

[00:45:23] Germany, Japan, USA, India from April to September so if you are interested

[00:45:28] please contact us to stay to reserve a slot for your for your project or if

[00:45:34] you interested bring the technology into your country then just feel free to

[00:45:39] email us lastly I want to show some fun image fun photos of our onsite work so

[00:45:46] the Drone EL can be not really relaxed work for example the pilot can

[00:45:51] sit on the chair control the Drone with RC and then the rest work will be

[00:45:57] smoothly running sometimes it's becoming a boring boring drob because the Drone

[00:46:03] is really smooth but what we need to take pay more attention is the

[00:46:08] raining situation so sometimes when there is a rain we need to build a shelter to protect our

[00:46:15] equipment and a beauty of this

[00:46:20] work is that we're traveling all around the world and sometimes we see lovely creatures in the lovely animals in the

[00:46:27] in the solar farm for example this one in Australia during the time we set up our equipment we got a visitor and he

[00:46:36] might be running want to join us later, thank you very much that's

[00:46:44] all I can sharing for today's webinar and here is my email address if you are

[00:46:50] interested please email us thank you very much thanks for your attention

[00:47:00] Niclas: Yan, thank you very much for this excellent presentation and

[00:47:05] very insightful and very also detailed the whole process and up to

[00:47:11] basically your visitors basically that you had in Australia during

[00:47:17] your inspection, so we move now to the

[00:47:22] Q&A part of our webinar so if you have any questions please type them in

[00:47:29] the chat box on the right side and so we will try to answer

[00:47:36] as many as possible during the given time so let us see what we have here

Webinar Q&A Summary

Q1. Is there any acceptable international standard for EL testing results to compare and evaluate?

Answer:

Yes. Currently, two standards are relevant:

1. IEC 6094-13 (2018) – This is the guideline for indoor EL testing.

2. IEC 62446-4 (in development) – This upcoming standard aims to define procedures for onsite / field EL inspection.

The industry hopes this new field-testing standard will be published soon to create a unified reference for solar professionals. Although various EL and PL imaging standards exist, the criteria for defect evaluation are still evolving.

Q2. Do the panels need to be at zero degrees to perform EL inspections with a drone?

Answer:

No. The drone uses a gimbal that can adjust the camera angle. As long as the panels are at a normal installation tilt, inspections can be carried out without needing a zero-degree orientation.

Q3. What is the resolution of EL imaging from the drone? Can you see microcracks? Can EL be done under a full moon?

Answer:

• Yes, EL can be performed under a full moon. The system uses filters that remove ambient light.

• The drone uses a high-resolution InGaAs camera, the most sensitive sensor for crystalline silicon EL signals (centered at 1150–1159 nm).

• While resolution is important, image quality also depends on processing and signal capture.

• The system can clearly capture tiny microcracks.

Q4. What are the environmental conditions required for drone-based EL inspection (rain, wind, ambient light)?

Answer:

• Rain: Inspection must stop. The equipment (DC power supply, electronics) is not waterproof.

• Cold temperatures: Not recommended for operator comfort and equipment stability.

• Strong wind: Drone flight becomes unstable; therefore, inspections are paused.

• General rule: If there is no rain, inspections can typically proceed.

A detailed list of conditions can be provided on request.

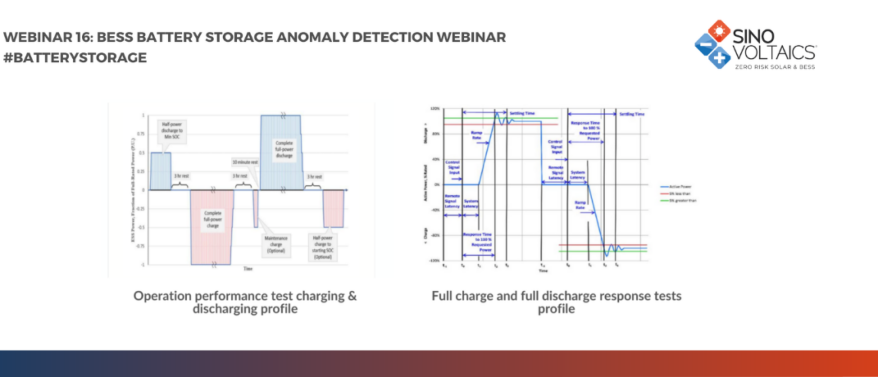

Q5. Is EL captured as video or images? What is the exposure time, and is it consistent during drone testing

Answer:

• The system captures images, not video.

• Two EL imaging technologies were evaluated:

o InGaAs camera: Lower resolution, higher cost, but best quantum efficiency → exposure time in milliseconds.

o CMOS-based systems: Higher resolution but require longer exposures (up to 1–2 seconds).

Using InGaAs allows fast drone scanning at 3–4 m/s while maintaining high image quality. Research comparing PL and EL techniques was also published with UNSW, detailing exposure requirements.

Q6. Are there regulations required before performing drone inspections?

Answer:

Yes, regulations vary by country.

Local partners typically handle:

• Drone registration

• Operating permits

• Hiring/appointing certified drone pilots

QAPS provides the technology, hardware, and software, while local partners manage compliance and operations.

Q7. How long did it take to inspect a 200 MW solar farm in Australia?

Answer:

For a 200 MW single-axis tracker system (~400,000 modules):

• With one drone → approx. 4 weeks

• With 2–4 drones → approx. 1 week total field inspection

Drone hardware is now affordable, so scaling up drones is no longer a major cost factor.

Q8. What are the main challenges for drone EL on large floating PV farms?

Answer:

Floating solar farms usually have regular, well-structured layouts, so inspections are straightforward.

The key requirement is:

• Building landing platforms close to the array, since drones cannot fly long distances back to shore for landing.

Landing directly on floating platforms ensures safe and efficient operation.

Q9. Can drone-based EL be used for EPC acceptance testing? How are criteria set?

Answer:

Yes, it can be used for EPC acceptance.

Some developers already require full-site EL inspection as part of their EPC specifications.

Acceptance criteria typically include “pass/fail” thresholds agreed between EPC and owner

QAPS can provide a default criteria template to help establish the baseline.

Q10. How can we quantify or predict power loss in a string based on different EL defects?

Answer:

This is a complex challenge. Current capabilities include:

• Predicting power loss based on uniformity scores when the dominant issue is shaded or “black” cells.

• Developing an Integrity Score representing defect density detected by AI.

• Working on correlations between Integrity Score and real performance to build a complete model.

About 60% of defect-type (EL-to-power-loss) correlations have been solved, which is a significant step forward given the diversity of EL criteria across the industry.