Introduction

Battery Energy Storage Systems (BESS) are becoming critical infrastructure for renewable energy projects, but they introduce new safety, performance, and lifecycle risks. This webinar on BESS Battery Storage Anomaly Detection brought together experts from Sinovoltaics and Volytica Diagnostics to discuss how risks can be mitigated through Factory Acceptance Testing (FAT) and continuous battery diagnostics. The session explored real-world findings, technology limitations, and best practices for safeguarding project value across the entire battery lifecycle.

Highlights

- FAT is crucial for BESS safety: One third of inspected BESS units had faulty fire safety systems, posing serious safety and financial risks.

- Performance testing must push design limits: FAT should validate systems at rated C-rates and emergency conditions to ensure real-world reliability.

- Continuous diagnostics protect long-term value: Volytica’s VDX engine continuously analyzes existing sensor data to detect anomalies and optimize battery lifetime.

- Battery chemistry matters: NMC offers higher energy density but shorter lifespan, while LFP provides longevity with operational and management challenges.

- Cooling systems are critical: Liquid cooling generally provides superior thermal control, though well-designed air cooling can also be effective.

- End-to-end risk management works best: Collaboration between Sinovoltaics and Volytica combines factory testing with operational monitoring for full lifecycle coverage.

Key Insights

Factory Acceptance Testing (FAT) as a Risk Control Measure

FAT is a decisive step in preventing safety incidents and protecting return on investment. Findings from inspections revealed that approximately one third of BESS units had non-functioning fire safety systems, a critical failure that could lead to battery fires and early decommissioning. Because FAT lacks standardized global protocols, testing quality often depends on supplier practices, client requirements, and time constraints. This makes it essential to define FAT scope contractually, ensure on-site oversight, and confirm software readiness before FAT. Effective FAT includes not only visual inspections, but also integrated performance tests, emergency shutdown simulations, and validation at full design limits.

Battery Diagnostics Beyond Commissioning

Many degradation and safety risks cannot be detected during factory testing alone. Volytica’s VDX engine addresses this gap by continuously analyzing voltage, temperature, and power data already available within the system—without additional hardware. This ongoing monitoring enables early detection of anomalies, supports warranty and residual value assessments, and provides actionable insights to extend battery lifetime. The growing adoption of such analytics, with contracts exceeding 5 GWh globally, reflects increasing industry recognition that monitoring is essential throughout operation.

Chemistry, Usage, and Degradation

Battery performance and safety are highly dependent on chemistry and operating conditions. NMC batteries prioritize energy density, making them popular in automotive applications but less ideal for continuous stationary use. LFP batteries offer longer life and better thermal stability but require careful management due to their flat voltage characteristics.

Usage patterns—particularly state-of-charge (SOC) windows, idling behavior, and temperature—have a dramatic impact on lifespan. Optimized SOC ranges can nearly double cycle life, while improper idling or high temperatures can rapidly accelerate degradation. Oversizing capacity remains a common industry strategy to meet warranty thresholds.

Thermal Management and Safety

Thermal control is a cornerstone of battery health. Liquid cooling typically provides more uniform temperature control and reduces inhomogeneous degradation, though air cooling can be sufficient if well designed. Every 10°C increase above 25°C roughly doubles degradation rates, underscoring the importance of robust cooling—especially in hot climates. While liquid cooling introduces risks such as coolant leakage, manufacturers actively mitigate these through design controls. More broadly, many fire incidents are linked to peripheral components (wiring, connectors, chargers) rather than cells themselves, reinforcing the need for holistic system monitoring.

Anomaly Detection and Insurance Perspectives

Battery fires are rare but high-impact events. Continuous anomaly detection—covering thermal behavior, balancing issues, and cell asymmetries—allows operators to intervene early. Insurance leaders such as Allianz and Swiss Re have identified performance monitoring as a key emerging risk mitigation strategy. Monitoring warranty violations and near-violation conditions provides operators with proactive control, enabling corrective action before irreversible damage or contractual breaches occur.

Conclusion

The webinar underscored that battery risk management does not end at the factory gate. Factory Acceptance Testing is essential for identifying critical defects before shipment, but long-term safety, performance, and value protection require continuous diagnostics and informed operational strategies.

By combining Sinovoltaics’ expertise in factory audits and FAT with Volytica Diagnostics’ advanced anomaly detection and analytics, project owners gain an end-to-end approach to battery lifecycle management. As BESS deployments scale globally and chemistries evolve, this integrated model represents a best-practice pathway for safer, longer-lasting, and more bankable energy storage projects.

Webinar Transcription:

Speaker 1 (Dricus de Rooij): 00:00

Hello everyone, and welcome. Good morning, good afternoon, and good evening—wherever you’re joining us from. Welcome to today’s webinar.

Today’s topic is “Real-Life Examples for Anomaly Detection with Battery Diagnostics.” We have 273 people registered, with many already joining. We see developers of large-scale PV and battery energy storage projects, insurers, financiers, and EPCs. A warm welcome to all of you.

It’s my pleasure to host this session. A special welcome to Claudius Jehle, CEO of Volytica Diagnostics, a key player in battery diagnostics. Good morning, Claudius—great to have you here.

A bit of background on Claudius: he previously worked at the Fraunhofer Institute as Energy Storage Diagnostics and Telematics Lead, and he is a frequent lecturer on battery topics, including battery degradation. Some of us also know him through the Battery MBA program, which several of our team members have participated in.

Also presenting today is Arthur Claire, our Head of Technology at Sinovoltaics, based in Switzerland. Arthur is an energy storage expert who previously worked in Hong Kong and has supported more than a dozen large-scale battery energy storage projects worldwide.

Special thanks to the teams who made this webinar happen: Christine Lustik from Volytica—thank you very much—and from our side, Sylvia, for organizing this session.

My name is Dricus de Rooij. I’m Managing Director at Sinovoltaics, based in Hong Kong, and I’ve been living in Asia since 2009. Sinovoltaics is best known for conducting factory audits and inspections of PV and battery energy storage components at factories in Asia.

Today’s session will last approximately one hour: a 30–45 minute presentation, followed by time for questions. If you have a question, please type it in the chat box. We’ll answer as many as we can—some during the presentation if relevant, and others at the end. We encourage interaction.

Quick check: can everyone hear me clearly? If you’re experiencing audio issues, please try reconnecting.

Our first presentation is by Arthur Claire, who leads our energy storage team at Sinovoltaics. Arthur will talk about Factory Acceptance Testing (FAT). Arthur, please go ahead.

Speaker 2 (Arthur Claire): 04:13

Thank you, Dricus, and good morning everyone. I hope you’ll find today’s session useful.

We’ll discuss the most frequent BESS issues identified during FAT. Just to clarify: when we say FAT, we mean Factory Acceptance Testing, not weight loss before summer.

BESS units typically come in 20-foot or 40-foot containers filled with batteries. FAT includes a series of tests such as visual inspections and functional tests to ensure performance meets expectations.

This step is critical because it marks the handover between the supplier—usually based in Asia—and the final client, who will own the BESS for the rest of its life, ideally 10 to 20 years.

I’ll start by explaining why FAT is important, then move on to the most frequent issues we encounter.

Speaker 3: 05:36

Let’s start with why.

Speaker 2 (Arthur Claire): 05:39

Why is FAT important?

First, it helps identify critical defects that could lead to serious incidents later—such as battery fires that may last for several days. Unfortunately, lithium-ion battery fires attract significant media attention. FAT helps mitigate this risk.

Second, FAT protects your return on investment. You want to ensure the BESS performs according to specifications. In one US project, containers were decommissioned due to a faulty sprinkler system. After shutdown, battery modules were stolen—clearly a worst-case ROI scenario.

Third, there is no universal FAT standard today. While standards like UL 9540 and UL 9540A exist, they focus on design qualification rather than manufacturing acceptance. FAT practices vary by supplier, client, and time constraints.

A common challenge is schedule pressure: suppliers often want to ship as quickly as possible, compressing the FAT timeline. This is usually a red flag.

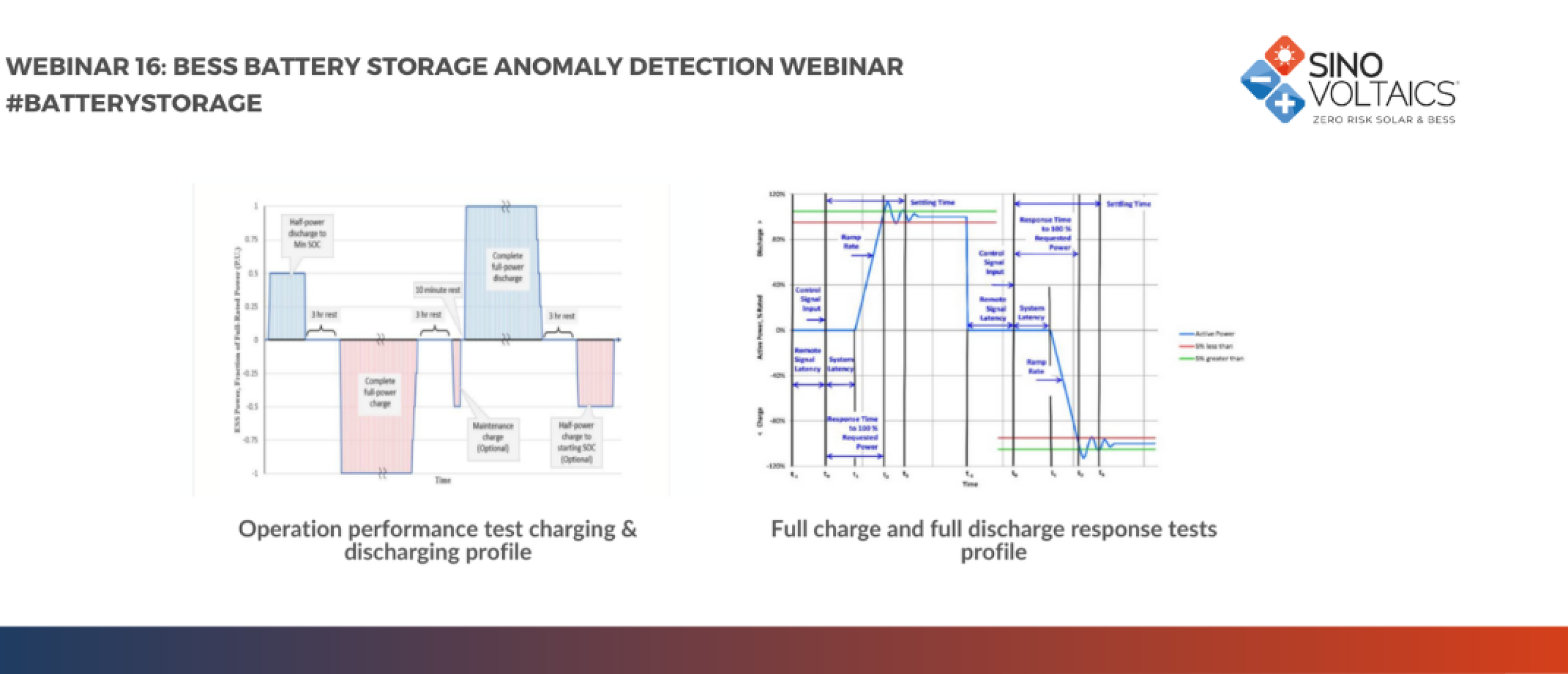

What does FAT include?

Visual inspection of the BESS

Component-level checks (battery modules, PCS, cooling system)

Charge/discharge cycles to verify integrated operation

Performance tests at system limits

Safety tests

Common issues we find:

1) Visual and labeling issues

While not performance-critical, appearance matters. We’ve seen misspelled company names or even the wrong company name on containers, as well as painting defects and physical damage.

Speaker 1 (Dricus de Rooij): 10:53

Arthur—quick question from Eric: does FAT mean final acceptance test or factory acceptance test?

Speaker 2 (Arthur Claire): 11:09

It means Factory Acceptance Test, the last test performed at the factory.

Speaker 1 (Dricus de Rooij): 11:15

Thanks.

Speaker 2 (Arthur Claire): 11:19

2) Fire safety systems not working

This is a major issue. In roughly one-third of cases, the fire safety system was not functioning. This is a critical component for early detection and mitigation of fire risks.

If you’re receiving BESS systems today, I strongly recommend verifying that the fire safety system works correctly.

3) Software issues

Sometimes FAT time is spent fixing software bugs rather than testing. Issues usually occur at:

The system integration level (EMS integration with PV, genset, grid, and loads)

Communication between PCS and BMS

These issues should be resolved before FAT, not during it.

4) Performance not meeting specifications

In some cases, performance targets are not met. This varies by project, but performance must be verified against contractual requirements.

Key takeaways:

Define the FAT scope early and include it in supplier contracts

Ensure on-site oversight during FAT

Complete software integration before FAT

Test systems at full design specifications (e.g., 2C or 3C if required)

That concludes my section.

Speaker 1 (Dricus de Rooij): 15:42

Two quick questions. First: is FAT conducted before shipping?

Speaker 2 (Arthur Claire): 15:57

Yes. FAT is the final step at the supplier’s factory—usually in Asia—before shipment to the client.

Speaker 1 (Dricus de Rooij): 16:23

Follow-up from Eric: what can be tested if the BESS is assembled on site and requires full grid support?

Speaker 2 (Arthur Claire): 16:47

There’s no one-size-fits-all answer. Some factories have grid simulators or load banks. At minimum, the battery system should be tested at the factory, ideally with the same PCS used on site.

Speaker 1 (Dricus de Rooij): 17:23

Are modules disassembled after FAT, or shipped installed?

Speaker 2 (Arthur Claire): 17:43

It depends on shipping regulations and supplier practices. Both approaches are used, and this should be clarified early.

Speaker 3 (Claudius Jehle): 18:43

Thank you, Arthur. I’ll now focus on what happens after commissioning, because battery risk management does not stop at the factory.

Not all problems can be detected during FAT. Batteries degrade over time, and performance depends heavily on usage.

I’m Claudius Jehle, CEO and co-founder of Volytica Diagnostics, a spin-out from the Fraunhofer Institute. We began monitoring batteries in 2012, starting with electric buses, and later expanded to stationary systems, trucks, and trains.

We’ve been developing battery diagnostic algorithms for over a decade. Our software, the VDX Engine, has been in operation for more than eight years.

We analyze data already generated by battery systems—voltage, power, and temperature—without installing additional hardware. From this data, we generate insights for:

Utilization and profit optimization

Lifetime extension

End-of-life assessment

Residual value certification

Safety and anomaly detection

Speaker 1 (Dricus de Rooij): 23:08

Question from Darius: is anomaly detection done at cell level?

Speaker 3 (Claudius Jehle): 23:25

We don’t analyze every single cell. A BESS may contain hundreds of thousands of cells. Instead, we use a patented approach based on extreme values—such as hottest, coldest, highest-voltage, and lowest-voltage cells—to detect anomalies efficiently.

Speaker 3 (Claudius Jehle): 24:12

Our software provides a full BESS overview and integrates into SCADA and condition monitoring systems. Users can drill down into individual containers, receive alerts by email, and monitor battery stress levels.

We also provide detailed battery health reports, covering state of health, residual capacity, round-trip efficiency, and safety indicators.

We are currently negotiating contracts exceeding 5 GWh globally, reflecting growing demand for continuous battery diagnostics.

Speaker 3 (Claudius Jehle): 26:41

Lithium-ion batteries mainly fall into three categories:

NMC (nickel manganese cobalt)

LFP (lithium iron phosphate)

Other chemistries such as LTO or solid-state

NMC offers high energy density but reduced lifetime margins. LFP offers longer life and robustness but introduces operational challenges.

Battery degradation depends heavily on temperature, SOC window, power levels, and idling behavior. For example, cycling batteries in optimized SOC ranges can nearly double lifetime compared to wide SOC swings.

Degradation mechanisms include formation of the solid electrolyte interface (SEI) and lithium plating, which can increase safety risks if not monitored.

Speaker 3 (Claudius Jehle): 40:42

Volytica continuously analyzes KPIs such as stress level, capacity, efficiency, and performance accuracy, providing recommendations to extend battery life.

Regarding cooling: liquid cooling typically provides more uniform temperatures and reduces degradation, though well-designed air cooling can also be effective.

Batteries rarely catch fire, but when they do, the consequences are severe. Many incidents originate from peripheral components rather than cells themselves, underscoring the need for system-level monitoring.

We provide continuous anomaly detection for:

Thermal anomalies

Balancing and symmetry issues

Cell quality and safety risks

This enables early intervention and safer long-term operation.

Q&A Session:

Q1: What should be the optimum ambient temperature for battery systems, especially in high-temperature regions such as Pakistan?

Answer:

In practice, the battery system should rely on its cooling design—either air-cooled or liquid-cooled—to maintain appropriate internal temperatures. These requirements should be clearly defined in the tender and technical specifications, as the cooling system is responsible for climatization rather than ambient conditions alone.

Q2: When using liquid cooling, is there a risk of coolant leakage into battery modules and short-circuiting the batteries?

Answer:

Such risks are known, but manufacturers are generally well aware of them and design systems to manage these risks carefully. Cooling systems are typically well controlled in modern BESS designs. While temperature management is important, many operational issues arise from other factors, such as SOC window and overall usage conditions.

Q3: If lower SOC is better for storage, why do manufacturers typically ship or store batteries at around 30% SOC?

Answer:

It is not universally true that “lower is always better” for all battery chemistries. High SOC storage can accelerate degradation, but very low SOC introduces risks such as deep undervoltage. Around 30% SOC is a practical compromise: low enough to reduce storage stress, but high enough to remain safe. In addition, transport regulations often mandate shipping batteries at limited SOC, commonly in this range.

Q4: Is depth of discharge best managed by operating between 10% and 90% SOC?

Answer:

It depends on the cell chemistry. As a general guideline, it is advisable to avoid extreme SOC limits and very deep swings. Operating within a slightly narrower window (for example, 90–10% instead of 100–20%) can help reduce stress and improve lifetime.

Q5: Is it possible to test a battery storage system combined with an EV charging system (DC/DC)?

Answer:

Yes. Testing storage systems combined with EV charging infrastructure is possible and supported. Interested parties are encouraged to reach out for follow-up discussions.

Q6: Besides charge and discharge tests, what major tests are conducted during Factory Acceptance Testing (FAT)?

Answer:

In addition to charge/discharge testing, FAT typically includes:

Visual inspections

Verification that each component functions correctly on its own

Performance and control response tests (e.g., how quickly the system reacts to commands)

Safety tests, including simulated shutdown scenarios to verify system behavior

Q7: How safe is LMO chemistry? Some manufacturers use hybrid LMO + NMC cells.

Answer:

LMO can generally be grouped closer to NMC-type chemistries than to LFP. While specific safety and performance characteristics depend on the exact formulation and generation, LMO shares more similarities with NMC than with LFP in terms of behavior and risk profile.

Q8: Does the analytics platform account for different battery cell characteristics from different manufacturers?

Answer:

Yes. The analytics platform is designed to work across batteries from multiple manufacturers, and the models account for differences in cell characteristics and chemistries.

Q9: How much cycle life is reduced when operating temperature increases from 25°C to 45°C?

Answer:

A common rule of thumb is that every 10°C increase roughly doubles the degradation rate. Increasing operating temperature from 25°C to 45°C can therefore significantly accelerate degradation and potentially reduce usable battery life to less than half. Avoiding sustained high temperatures is strongly recommended.

Q10: What is the best C-rate for charging and discharging to maximize battery life?Answer:

This depends on the specific cell type, but as a general rule, lower C-rates are better. For most standard chemistries, charging and discharging at ≤1C is generally unproblematic. One important caveat is that charging at around 1C at low temperatures (below ~15–20°C) can increase the risk of lithium plating. Operation above 1C depends strongly on the specific chemistry and cell design.

Q11: Are there examples of LFP battery fires, and what are their root causes?

Answer:

Transparency around root causes is limited. Some LFP fires are believed to be linked to cell-level issues, but in many cases detailed analysis is not possible because the system is destroyed during the incident and monitoring data is unavailable. Researchers such as Professor Paul Christensen (Newcastle University) track battery fire incidents, including those involving LFP cells, but definitive conclusions often require pre-event monitoring data.

Q12: Does the software monitor warranty violations?

Answer:

Yes. The software monitors both warranty violations and near-violation conditions. Detecting when a system is approaching warranty limits is critical, as discovering a violation after it has occurred is often too late to take corrective action.