This webinar focuses on the detection and management of microcracks and other inherent defects in solar cells during the manufacturing process, using electroluminescence (EL) imaging technology combined with advanced software analysis. Microcracks, which are invisible to the naked eye, can significantly reduce the performance and lifespan of photovoltaic (PV) modules by causing inactive or malfunctioning cells. The webinar is hosted by Sinovoltaics, we are specializing in quality inspections and audits for the PV industry, featuring experts from the team who explain the importance of mass-scale inspection and defect detection.

The presentation outlines how EL imaging is a key test performed in PV factories but is often manually reviewed, which can lead to overlooked defects. To address this, Sinovoltaics developed Selma EL Mass Analysis, a self-learning software capable of analyzing 100% of modules instead of relying on sampling methods, which are prone to missing defects. This approach ensures high accuracy in detecting over 15 types of defects, including microcracks, soldering faults, and cell efficiency mismatches.

Two real-world case studies from factories in China and Vietnam demonstrate the software’s effectiveness in identifying and removing defective solar modules before shipment, significantly improving project quality and reducing risks. The webinar also covers practical aspects such as factory cooperation, quality standards, and the challenges of testing modules post-installation.

The session concludes with a Q&A where technical questions about microcracks, detection methods, software capabilities, and industry standards are thoroughly addressed.

Highlights

• Microcracks in solar cells are invisible to the naked eye but can be detected using electroluminescence (EL) imaging.

• Selma EL Mass Analysis software enables 100% automated inspection of solar modules at factories, reducing reliance on sampling.

• Over 15 different defect types, including microcracks and soldering faults, can be accurately detected and filtered out.

• Case studies from tier-one factories in China and Vietnam show 2.6% to 3.56% of modules replaced due to defects.

• The software integrates into factory production lines to provide real-time defect detection and module rejection.

• Post-installation microcrack detection is labour-intensive and inefficient, making factory-level inspection critical.

Key Insights

• Importance of EL Imaging in PV Quality Control: EL imaging is a core diagnostic tool that reveals microcracks and other defects invisible to humans. Since solar modules are made of thousands of interconnected cells, even small cracks can cause significant power loss by increasing resistance or causing inactive cells. This highlights the critical need for precise and comprehensive quality control to safeguard the electricity output and longevity of PV projects.

• Limitations of Manual Inspection and Sampling: Traditional factory inspections rely heavily on manual review or sampling, typically testing only a small fraction of modules. This approach risks allowing defective modules into the supply chain, potentially causing underperformance in large-scale solar projects. The Selma EL Mass Analysis software addresses this by analyzing all produced modules, ensuring no defective piece is overlooked, thereby reducing financial and operational risks for developers.

• Self-Learning Software Enhances Detection Accuracy: The software continuously improves as it processes more EL images, learning to identify emerging defects more accurately. This adaptability is crucial in an evolving industry where new cell technologies and defect types (such as those associated with MBB modules) emerge, ensuring inspection remains relevant and effective.

• Factory Collaboration and Quality Standards Are Vital: The webinar stresses the importance of establishing clear EL quality standards in contracts with factories. Factory standards are often lenient, allowing certain defects to pass. Buyers can raise quality levels by implementing their own stricter standards, which the software can enforce. This cooperative approach between buyers and factories helps elevate product quality and transparency.

• Impact of Defects on Long-Term Module Performance: Microcracks may not immediately cause power loss but tend to worsen over time under environmental and mechanical stresses, such as wind load or temperature changes. This long-term degradation risk makes early detection and removal of defective modules essential to prevent future performance losses and possible project failures.

• Challenges with Post-Installation Testing: Detecting microcracks after modules are installed is costly, time-consuming, and operationally complex, requiring specialized equipment and nighttime conditions for EL imaging. This underlines the advantage of conducting thorough inspections at the manufacturing stage to avoid expensive field diagnostics and potential warranty disputes.

• Cost-Effectiveness of Mass Inspection: Although using advanced software to inspect 100% of modules might seem costly, it is ultimately more economical than dealing with underperforming modules and warranty claims in the field. The ability to replace defective modules before shipment protects the integrity of large-scale PV investments, offering superior value to project developers.

• Software’s Flexibility and Customization: The Selma software is highly adaptable, allowing users to define specific defect criteria based on project needs and factory agreements. It can quickly learn new defect types with as few as dozens of images and apply different acceptance standards simultaneously in various factories, making it a versatile tool for diverse project requirements.

• Global Reach and Industry Adoption: The technology is already widely adopted across major factories in Asia, including China, Vietnam, Taiwan, and South Korea, serving clients targeting markets worldwide (USA, Europe, Australia). This broad acceptance underlines the growing recognition of the need for rigorous PV quality assurance and the effectiveness of automated EL analysis.

• Human vs. Software Analysis: Though human analysis remains a component in verifying software results, automated EL image analysis surpasses manual inspection in efficiency, objectivity, and consistency. Software reduces human error and fatigue, ensuring continuous and comprehensive quality control, a critical advancement in handling the massive scale of modern PV module production.

• Microcracks and Manufacturer Claims: Manufacturers sometimes claim microcracks have no impact on output power, but the webinar clarifies that microcracks represent a latent risk that can grow and degrade module performance over time. Developers should insist on strict quality standards and early defect removal rather than relying solely on manufacturer assurances.

• Integration into Production Lines: The software’s capability to analyze EL images in real-time during production enables immediate identification and removal of defective modules before packing and shipping. This inline inspection approach ensures defect-free shipments and reduces the risk of defective modules reaching the project site.

• Future of PV Quality Assurance: The integration of advanced imaging, AI-powered software, and established quality standards represents the future of PV module quality assurance. Mass EL inspection transforms the quality control paradigm from probabilistic sampling to deterministic, comprehensive screening, raising industry reliability and project performance.

Conclusion

This webinar thoroughly explains the critical role of EL imaging combined with advanced software solutions in managing microcracks and other solar cell defects for large-scale PV projects. It highlights the limitations of traditional sampling-based inspections and the advantages of mass inspection using Selma EL Mass Analysis software. By adopting these technologies and raising quality standards, developers can significantly mitigate risks, ensure higher module performance, and extend the lifetime of their solar investments. The offered free trial underscores Sinovoltaics’ commitment to raising industry standards and supporting large-scale PV project success through cutting-edge quality assurance tools.

Webinar Transcription:

[00:00] During this webinar, we talked a lot about microcracks, but actually, there are plenty of other types of defects you can spot using electroluminescent images. To keep it simple, we’ll just call them microcracks. The thing with microcracks is that you can’t see them with the naked eye, but they become visible when you use electroluminescent imaging, or EL imaging. For top performance, it’s super important that all these connections work properly so the electricity generated can flow smoothly without any interruptions. High-resolution electroluminescent images are...

[00:33] are being uploaded, and while that’s happening, the software starts analysing them and defects are automatically marked.

Hello everyone, good morning or good afternoon. Welcome to this webinar. Today we will talk about the mass detection of cell-inherent defects with the use of our software. This webinar has only been organized at the last minute, and we have over 150 people signed up, so I’d like to welcome everybody.

For those who don’t know me yet, my name is Benoit, and I’m International Business Development Director at Sinovoltaics.

[01:18] and also joining this webinar is Dricus, Managing Director, and Niclas, our Chief Technology Officer.

Our company, Sinovoltaics, is a technical compliance firm in the PV and ESS industry, best known for performing quality inspections and audits at factories in Asia.

The main issue we’re focusing on today is defects that occur in solar cells and how to prevent those on a mass scale, with the objective of having only flawless solar modules in your PV projects.

[01:18] and also joining this webinar is Dricus, Managing Director, and Niclas, our Chief Technology Officer. Our company, Sinovoltaics, is a technical compliance firm in the PV and ESS industry, best known for performing quality inspections and audits at factories in Asia. The main issue we’re focusing on today is defects that occur in solar cells and how to prevent those on a mass scale, with the objective of having only flawless solar modules in your PV projects.

[02:03] Project-wise, we’re starting with how defects can be detected using EL imaging, and we will explain what solar cell defects you can expect to find at PV factories. From there, we make the jump to our in-house developed software and explain how it can be used for the detection of defects on a mass scale.

Then, to show you how the software works, Dricus is going to walk you through two real case studies: one of 36 MWand one of 68 MW. In total, we expect the presentation to take about 30 minutes, followed by a Q&A session.

[02:39] At the end, we finalize the webinar with a very special offer for those who develop large-scale PV projects. We can now offer some free trials. Dricus will explain more about this at the end of the webinar.

Some basic information: the webinar will be recorded, and everybody who signed up will receive an email with the recording afterward. During the webinar, you can ask questions in the chat. If you have questions, you can put them in the chat, and we can answer them directly or later during the Q&A session.

[03:14] Before we dive into the case studies, we’ll have a look at EL imaging: what microcracks are and the different types of microcracks you can expect when you build PV projects.

During this webinar, we speak a lot about microcracks, but in fact there are many other types of defects that can be found when using EL imaging. For the sake of simplicity, we will just call them microcracks. The thing about microcracks is that they cannot be seen with the naked eye, but they can be made visible.

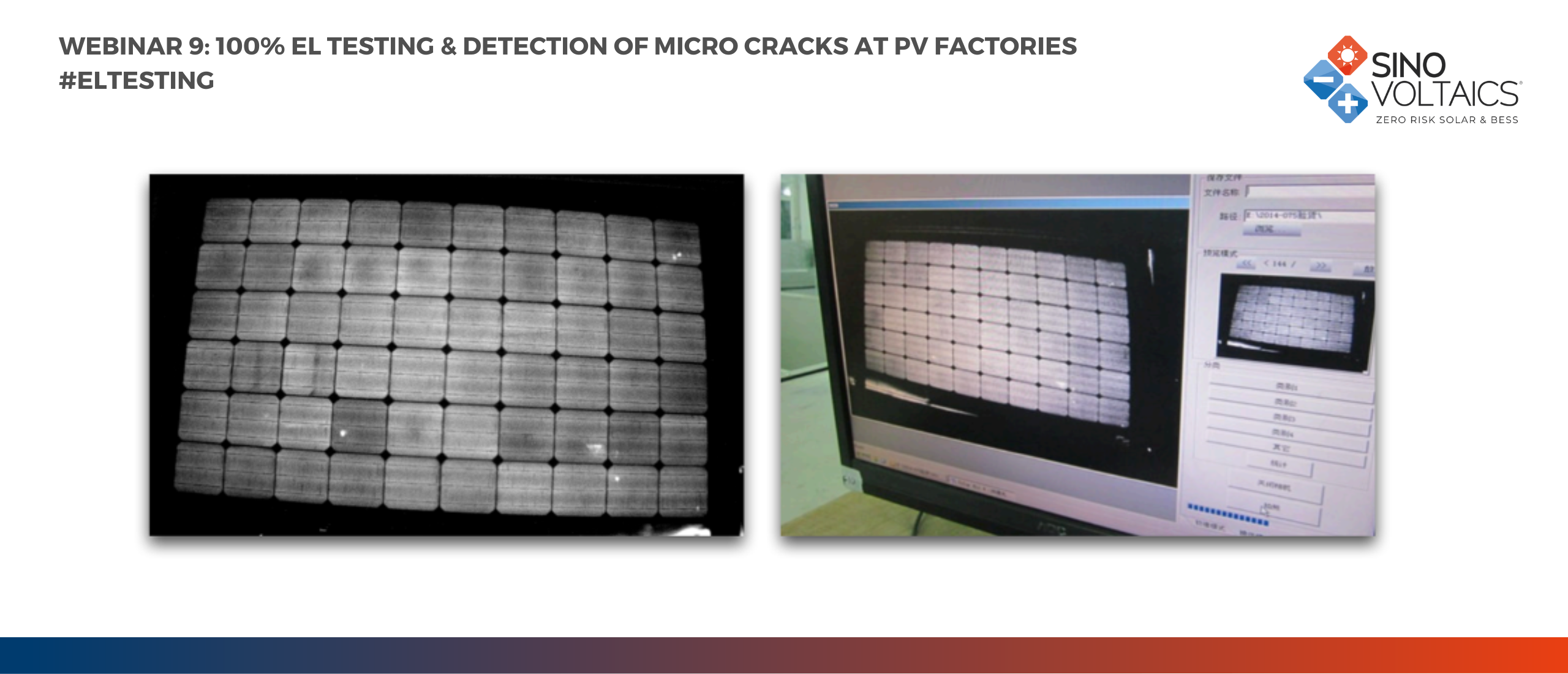

[03:59] Using electroluminescence imaging, or EL imaging. EL imaging is one of the key tests during production. EL imaging is performed at PV factories on all solar modules. However, factories review the images manually with the naked eye, and defects can be easily overlooked. This is how modules can end up with cracks in your project.

We all know that large PV plants are built using tens of thousands of connected solar modules, and those solar modules in turn consist of hundreds of thousands of connected solar cells.

[04:41] For excellent performance, it’s critical that all these connections are functional so your generated electricity can flow without interruption. Microcracks inside solar cells cause malfunctioning and inactive solar cells. Such defects can create resistance and cause the power output of your solar modules to drop.

Microcracks mostly occur during manufacturing and can also occur later during transport and installation. We also see that cracks can get worse in the field over time.

[05:17] Therefore, underperformance can also increase over time. On the left, you can see the cover of our own EL standard. When buying solar modules from a PV factory, it’s always important to be aware of the quality standard agreed upon in the contract.

EL defects are listed in factory EL standards, but those standards are usually not very strict, which means some defects are allowed to pass. We therefore recommend implementing your own EL standard, or we can help you adjust it.

[06:00] The factory standard. This will directly raise the quality level of your modules, and most PV factories accept those requests.

Now I will let Dricus continue with the following slides.

Thank you, thank you, Benoit, and hello everyone. For those who don’t know me, my name is Dricus. I will continue here and tell you a little bit more about our in-house developed software called Selma EL Mass Analysis.

To start, let me tell you why we developed our own software for EL reviews, because mass-scale inspections at factories are still something very special in the PV industry.

[06:52] The thing is, most inspection companies only perform sampling at factories. Let’s say you order 10,000 solar modules; most companies would only sample 125 or 200 pieces. With sampling, you get a general idea of the overall quality of a batch.

But the reality, and the disadvantage of sampling, is that many defects go undetected and actually end up in your PV project. We see it as our mission to reduce risks for large-scale PV projects as much as possible.

[07:44] Over three years ago, we thought there must be a better way to do this. Our CTO, Niclas, who is also on the call for the Q&A session, decided together with our development team to create a software solution.

With this software, we are able to inspect all solar modules based on EL analysis. There are over 15 different defects that it can detect, and as the software is self-learning, it gets better as it processes more images.

[08:26] We’ve been around as a company since 2009, so we have EL data with different types of defects going back over 10 years. The software is constantly being fed this data and continuously improved. Even defects that may occur in the future can be picked up quickly, making the system highly accurate.

The way it works is as follows. Once production starts—actually, let me go to the next slide, as it gives you a brief overview of the software.

[09:09] Once production starts, our team is usually present at the factory. We integrate this EL mass analysis into our inline inspections. The way it works is that we set up a data stream to our server inside the factory.

High-resolution EL images are uploaded, and while that’s happening, the software starts analyzing them and defects are automatically marked. This happens on the fly, so we can keep up with high-speed production. Then, when any defects are detected…

[09:52] When defects are detected, the serial numbers are then sent back to the factory where our team is present, and they remove those modules from your shipment. The result is that all solar modules are quality-checked before they leave the factory. Now we’ve put together two case studies to show you a real idea of what this can mean for your projects. The first case study is a very typical large-scale project: 36 megawatts at a Tier-1 factory in mainland China, using mainstream mono PERC technology.

[10:32] Half-cut cells, 455 W modules, and production was fairly recent, in Q1 this year. If you look at the results on the right, you can see the types of defects that the software found.

The most common defects are single cracks, marked here in yellow, cross cracks, cell-piercing cracks—which go from left to right across the cell—and dendritic cracks, shown on the left in red.

[11:23] In total, we found cracks in 2,880 pieces, which accounts for 3.56%. That means all 2,880 modules were replaced. As Benoit mentioned, when you apply such a strict selection of permitted versus non-permitted defects, it’s very important to agree on a clear quality standard with the factory. The defects shown here should typically be replaced.

[12:08] To summarize: Tier-1 factory, over 80,000 modules, 2,880 replaced, and 100% inspected. What’s important after this exercise is that we also oversee the packing and loading of the containers, to ensure that the rejected modules do not end up in your shipment. Therefore, EL reviews are typically part of an inline inspection.

Now I’m going to show you another case study.

[12:53] This case study is from a factory in Vietnam. We have a permanent team in Vietnam, and this project was at one of the larger manufacturers there. Most of the products are shipped to the U.S. market, but there are also European and Australian clients.

The project involved large 540 W bifacial modules, totalling 68.9 megawatts and over 127,000 modules, where we again performed 100% inspection. The most common defect here was soldering faults, marked in green.

[13:38] In green, and that means that the solder connections of the bus wire are not done properly. You get this shading effect on part of the cell. In most quality standards, that’s not allowed, so in this case we were able to replace those.

Then again, single cracks, cross cracks, and cell-piercing cracks are the most common ones. Cross cracks, shown here in light blue, typically get larger over time, and it can get worse to the point that it might create an inactive cell part.

[14:20] This can degrade performance in the long term. For this project, we replaced 3,321 pieces, which is 2.6%. Here is a summary again: Tier-1 factory in Vietnam, 127,600 pieces, and we replaced 3,321. What used to be the case with most inspection jobs is that for a 68-megawatt project, you would divide it into 13 or 14 batches of five megawatts each. For each batch, you would test 125 pieces using sampling, and then decide according to the AQL how many defects were acceptable.

[15:13] Based on the AQL, you would decide whether a five-megawatt batch was pass or fail. That is still what happens in many cases, but it doesn’t help you as a PV project developer if you want to be sure there are no defects in your PV plant. By replacing these 3,321 pieces, you remove serious cell-inherent defects, including microcracks, from your shipment. That’s it for the case study. We’re going a bit faster than expected.

[16:00] We’ve already passed the case studies. One thing I forgot to mention is that if you have any questions, please feel free to type them in the chat so we can answer them at the end of the webinar. Next slide: here are some of our references and examples of companies that see the value of mass-scale inspections. You could say they are quality leaders, in the sense that they remove 100% of defects from their projects.

[16:45] The next slide is about adoption by factories. We’ve been receiving very positive feedback over the years from using our software at factories. The process is very transparent. Typically, the quality standard comes either from the buyer or from the factory. If it’s a factory standard, sometimes we help the buyer assess whether the standard is strict enough and whether adjustments are needed. From there, we take that as a basis for the inspection.

[17:27] Basis for the inspection, and all the major factories have adopted the software. They are open to it, and we’re able to implement it successfully at factories in Asia—not only in mainland China, but also at factories in Vietnam, Taiwan, and South Korea, at pretty much all factories in Asia. So I’m already at my final slide here. What we would like to offer you today is a free trial. For this time, we’re offering 100 megawatts as a free trial.

[18:21] This free trial is for companies that are developing large-scale PV projects. The requirement is that you have to buy directly from factories in Asia. If that’s what you’re doing, you can really benefit from this free trial. We give away a maximum of 10 megawatts for review per company, and it doesn’t matter which factory you’re buying from in Asia—it can be any factory. It has to be a project this year so we can really show you the results.

[18:58] We can really show you the best benefits for your PV project. So far, we’ve had tremendous feedback from our clients. Many have no idea exactly what they’re buying, but this gives you full insight into the state of the solar modules. Of course, this is only one test—imaging—but it’s one of the key tests you can perform. Aside from that, there’s IV testing, verification of raw materials, and visual inspections.

[19:36] EL imaging is really a key test, and we believe that any developer of large-scale projects can benefit from using this software. That’s the end of the presentation. This brings us to the Q&A session. Let me have a look at what questions there are. I see some interesting questions here. Our CTO, Niclas, is also here. He has been leading the development of this software, so who better to answer these questions?

[20:26] Here’s the first question. Niclas, maybe you can come to the stage and answer this one. It says microcracks. This question is from David. He says microcracks lead to inactive cells, but manufacturers claim there is no influence on output power. How do you fight back?

Yeah, this is a good question. I mean, there’s certainly—first of all—the argument comes from the perspective of a standard where this is not enforced strictly.

[21:18] …of a standard where this is basically not enforced strictly. So if you would, for example, agree with a manufacturer on the EL standard, so to say, I would find it quite challenging to fight back. I mean, this is about fighting back, or whatever you would call it.

It is actually very prudent to have a very good quality center in place when it comes to arguing about this. The argument of why microcracks are basically a peril to the long-term success of your projects is that there is not a given outcome, but there is a potential risk.

[21:59] There is a potential risk for any cell, or for any cracks in cells, to grow over a longer operational time. Your modules and the cells that are encapsulated within that module are basically laminated within the module and are subjected to all kinds of environmental and mechanical stress forces.

[22:30] They are outside, in the open, in Mother Nature, over a long time. Of course, you want to reduce this kind of impact, or the potential of this impact, by getting rid of modules with such cracks very early on. If you already have some basic cracks, they may expand over time due to pressure forces. Again, it’s a potential risk, which is also shown in studies we’ve seen.

[23:06] Companies that do analysis in the field have seen that cracks can grow over time. Not for all cracks—it’s not a given—but the potential is high. This is why you want to get rid of this risk, regardless of the percentage of cracks that could potentially grow. For each crack, there is at least some potential, so you want to start with a very clean batch of modules in your project.

[23:38] It also starts with a good standard, which makes fighting back easier.

All right, there are quite a few more questions. I’ll just pick another one. The question is: can Selma be used during production, for example, to replace or be jointly used during production?

It is actually used during production. We use the software from the moment production starts, and we use it throughout production. From the moment the…

[24:18] Actual EL imaging is performed inside the factory. The data is uploaded to our server, and we review these EL images. So if you have, let’s say, a 50-megawatt project, and production lasts 25 days, it means that during those 25 days we are continuously reviewing the EL images.

Years ago, we would do this with manpower. We used to have many people looking at big screens and looking for cracks, but because the volumes we inspect and the project sizes have been going up over the years, it’s impossible to do it manually these days. So it’s definitely performed during production.

[25:00] This is maybe a question for you, Nick. The question is: what’s the smallest size of microcracks that can be detected?

The smallest size—well, we are capable of detecting so-called small V cracks that you would find in MBB modules. That’s in the very smallest millimeter range.

[25:43] You have these newer MBB modules, which are also more prone to so-called MBB cracks. These are cracks at the soldering edges of the cell, and even these can be detected. That’s currently the smallest kind of crack that you can find on such projects, and we can deal with that fairly well. There’s actually another question about this, Nick. The question is: do you consider V microcracks?

[26:19] That’s exactly what you were just mentioning. He’s referring to genotype tiling ribbon lines as a defect worth filtering out at a certain number. There are different schools of thought about this. But let me be clear: any kind of crack could potentially grow over time. There is potential, but there’s also another perspective for these new types of cracks, which are very small.

[27:00] It becomes a question of how perilous the impact is. Normally speaking, you would need to look at this in the long term, based on project performance. These projects have only been installed fairly recently, so the impact is still being evaluated. And keep in mind, this is also new technology. These issues come from newer technologies, which—even in all honesty—are still very challenging to manage.

[27:36] Very hard to manage, also for factories, even though there have been many improvements made in this field. With us, of course, you can filter them out. After all, it also depends on the criteria that you set for your project.

Maybe that’s a good way to put this. Of course, it all boils down to the quality standard that you agree on with the factory. If the factory is confident and agrees that such small V cracks are not allowed, our software can find them and we can replace those modules.

[28:13] However, many factories now tend to be a bit more lenient when it comes to these very small cracks. It’s something to look at on a case-by-case basis, and it also depends on the factory. We are always willing to be as strict as possible, but in the end it’s a cooperation between a buyer and a factory. You also need to agree on reasonable requirements that can be executed, because factories produce on a very big scale. So it needs to be realistic. Obviously, we can detect those cracks, and if allowed according to the standard, we can filter them out.

[28:56] Let’s have a look. Has the software analysis been compared to human analysis to prove accuracy and reliability, and so forth? Yes, it has. Years ago, we did all the analysis manually. We have gradually been switching to our software. When we find defects, the results are communicated to the factory, and the factory reviews those results through human analysis. They then confirm whether it is or is not according to the standard, so there is always a human factor involved.

[29:47] All these results are stored, and if the software previously picked up something that was not actually a defect, that feedback is immediately fed back into the software. It has been continuously improving, and nowadays it’s much more effective than human analysis.

Nic, maybe a question for you: can defects caused by microcracks be detected by analyzing the electrical specifications through flashing?

[30:33] And that’s immediately fed back to the software, so it has been continuously improving. Nowadays, it’s much more effective than human analysis.

Nic, maybe a question for you: can defects caused by microcracks be detected by analyzing the electrical specifications through flashing?

Yeah, this is an interesting question. I would say with limitations. For example, we have had cases in the past where we had to resort to—how to say—

[31:21] Affirmative tools, so to say. Well, years before the software, you could already see on the IV curves of flash tests that if the impact of the cracks was already present at a micro level, it would be mirrored in the electrical specifications.

For example, on the IV curve you could see some kind of step pattern, like stairs. The step pattern on the curve would be very minuscule, but you could see it.

[31:54] You could see this, and this would actually point to the potential existence of such cracks. We had a few cases where we did this correlation, so it certainly exists.

However, I would not deem this a sufficient exercise to do mass-scale analysis to be really sure that the modules are free of cracks. For this purpose, I think this tool is too weak, but it does help with correlation in some cases.

[32:27] Correlation in some cases, for sure.

Okay, the presentation was a bit fast, but we have a ton of questions, so we can keep going like this for a while.

Let me see—a commercial question: do most manufacturers add a price premium for slightly stricter panel acceptance criteria? The answer is no. Most factories do not, unless you go to the other extreme and impose a standard that requires a double-digit percentage of modules to be replaced. In that case, it really becomes very intensive.

[33:19 For factories, it really requires much more manpower, and in that case we’ve sometimes seen price premiums. But nine out of ten times, there is no price premium.

There are also quite some buyers who simply follow factory standards, and there is still plenty to find and plenty to filter out.

A question about PV projects in Indonesia: I’d like to know about your experience with QA for solar projects in Indonesia. There is actually a nice…

[34:13] PV factory in Indonesia, and we have been doing inspections there as well. It’s a Suntech factory, and they mostly produce for the local market and for the U.S. market.

Okay, what else? This is Mel asking: can you change the pass/fail criteria in the software, for example, use harsher criteria?

Yes, this can certainly be done. The software detects and filters any defect, and then we can apply so-called pass/unpass criteria.

[35:06] Filter on this, so this is certainly doable.

Here’s another interesting question. The question is: should an importer of solar panels test each container after arrival?

Let me answer this, because it’s actually a good question. Look, we’re a testing company, right? So usually, from our perspective, the more you test, the more certainty you have.

Cracks can occur during manufacturing, but they can also happen during handling.

[35:55] You know, if you have a professional EPC, any handling damage can certainly be minimized. What we see is that during transport, if you follow all best practices in packing, there is actually very little damage done to solar modules.

Now, there are exceptions. If a module is transported by truck for 600 kilometers over a bad road, sure, damage can be done. But on regular routes, for example from Shanghai to the main ports of Hamburg, Rotterdam, or Antwerp in Europe, there are very few cases of damage.

So should you…

[36:48] Then do another test upon arrival? From our experience, if you already checked 100% at the factory, the best way to do it is to unpack the containers and directly install them. The reason for this is the following: those modules have been 100% checked, and there is a very small chance something happens during transport. It’s much better to spend that testing money to look at your plant maybe in one, two, or five years and run some tests to optimize performance. Now, what’s going to happen if you do test…

[37:23] After the modules arrive, someone will come in, unpack the modules, test them, and fine—you get some results. But don’t underestimate that the handling of these modules can also create damage. If there’s damage, then maybe the factory will say it was caused by the testing company, and the testing company will say it was probably the shipping. So you basically create a liability problem this way, so it’s much…

[38:01] Easier to do 100% inspection at the factory and then be assured everything is in top shape and directly installed. That’s my opinion.

There are definitely other people with different opinions, but that’s how we see a lot of successful projects being done.

Let me have a look—this is an interesting question. Nick, have a look: what is the most efficient and quick method to check for microcracks on panels of a large project that are already installed on site?

So my quick answer…

[38:51] There’s no efficient or quick method, okay—but go ahead.

Yeah, I fully agree with this. It’s something I’ve also discussed with other colleagues in the industry. It’s quite a topic.

Basically, what you’re looking at with this question is mass checking of the modules using EL imaging. What happens is that electroluminescence imaging needs to be done under certain conditions. For example…

[39:29] With the current technology available, you need to either cover the modules or do it at nighttime to perform EL imaging. For this, you need portable equipment. We actually have this, and we have also been doing this kind of commissioning assessment.

But let me tell you, in all honesty, it’s a very tedious task—especially when it comes to large installations. You need a huge volume of equipment and a huge volume of…

[40:01] Of manpower. With the current technology available, you have to power up the modules at nighttime and then go from module to module.

We also have special equipment to test whole strings, but still—when we talk about, for example, 100 megawatts—you end up needing weeks, probably months.

There have been attempts to do this with drones, and that question may also be in the back of people’s minds…

[40:28] …in the back of the mind for this question, but it’s also not very efficient at the moment—especially when it comes to stability and holding patterns of this kind of vehicle while flying and powering up whole strings. It’s very tedious.

There might be some solutions coming up in the future, but they will not be based on EL, and we still have to see whether they would enable us to detect microcracks.

Maybe the fastest way to have at…

[40:59] At least some kind of preliminary assessment could be done using thermal imaging. You cannot see the cracks themselves, but you can at least see the impacts that come from those cracks, such as hotspots.

When there is enough resistance and heat built up at a localized level in the cell, you can detect it and then investigate further. But on a mass scale—no.

And this is why we take a preemptive…

[41:28] …approach, and that’s why we also do this at the factories and do not underestimate the cost of doing it.

If you really have a field full of cracks and you’re going to try to solve that on site, it’s difficult. With most companies’ equipment, I think they can test maybe 150 modules per night.

So then you already have a team with equipment going out at night, and then the question is: how many pieces are you going to test?

[42:03] …to test. These are inspections that can take many days, weeks, or even months. It can be very easily prevented, because you can filter defects out at the factory automatically with software.

So it can be troublesome if you have a field that is really affected.

Another question: are microcracks more critical in frameless modules due to bending of the module because of wind load?

I’ve seen quite some frameless modules that are actually passing all the…

[42:47] Mechanical load testing and wind load criteria. I’ve seen frameless modules that are pretty much as strong as framed modules.

Unless you have a different take on that, Nic?

No, I fully agree. In the end, it all boils down to the overall design and choice of materials.

Yeah, I fully agree with that point that was made already.

This is an interesting question, but maybe hard to answer: how do you quantitatively positively correlate critical parameters, i.e. size…

[43:32] Length, etc., of micro defects to the lifetime power loss of a module. Yeah, this is almost an academic question, right, Nic? I know you do a lot of research on this. Is there a simple answer to it?

Very simple answers—well, yeah. Since I have this discussion often, it’s hard to say. That’s just a lack of data. There are some indications, certainly when it comes to the positioning of the cracks and the impact, and also location and shape.

[44:07] You could probably correlate shape with size or length, but the long-term impact—there’s very little data. There are also very few research papers that have actually looked at this and compared it.

I believe it will take many more years, probably decades, before we have sufficient data. Then we can look into historical patterns of crack development and impacts.

[44:42] It very much requires that you do baseline work in the beginning, meaning you look at the state of the module at the very beginning. Otherwise, you will never know how degraded it is or what the impact was.

With the work that we do, we collect a lot of this data, and we also lay some groundwork by cooperating with academic institutions to support this.

[45:10] Another good question: manufacturers also analyze EL results to apply factory criteria. That’s right. Is your added benefit that Selma is more accurate or reliable in finding defects than the manufacturer would? Can you explain why default manufacturer analysis is insufficient?

That’s a very good point. There are two sides to this.

[45:49] First, factories have their own criteria. The first thing is to look at those criteria and see if they are strict enough. It’s not only about being strict, but also about being complete.

If a standard does not include a defect, that defect is automatically considered not important and will pass. So the standard itself needs to be reviewed.

[46:35] If you follow a factory standard, the reality is that there are at least two moments in production when EL imaging is done: just before lamination and after final assembly as a final quality check.

The step just before lamination is critical, because if you find heavy cracks there, the factory can still make repairs. This is very common. During inline inspection, we also supervise this, and we see that quite a percentage of modules can be repaired and will pass.

[47:12] That’s the first step. The final check is when the factory performs EL imaging and someone physically reviews the images.

There are many variables that can influence the result. First is the human factor—someone looking at a screen all day. It’s very tedious, and that person might take breaks and not always be fully attentive.

[47:49] Second, is the EL equipment calibrated? What is the resolution of the images? Some factories have new equipment, some have old equipment. Sometimes the resolution is too low to see much.

And of course, yield is important to factories. Why would you reject one or two percent of modules if nobody is checking closely?

So our job is to make sure the agreed standard is properly followed and implemented.

[48:26] Another question: flexible panels—how do you see the relationship between flexible panels and microcracks?

That’s interesting. Most flexible panels are not suitable to be bent much. If you take semi-flexible IBC cells and flex them ten times, then do an EL test, there’s a very good chance they’ll be full of cracks.

|It really depends on the technology. Thin-film technologies may be more suitable as truly flexible modules, but most flexible modules can crack as well.

[49:23] We could go over all the different flexible module technologies, but in most cases we see that the cells can crack.

Okay, another question: how fast can the system be ready for a completely new assignment using different EL criteria? Are you using your own criteria, or can it be adjusted easily? How fast can the system be trained for a new defect model?

[50:08] We can almost instantly switch to new criteria as long as they are clear. We have teams at different factories at any given time, so we use the software simultaneously with different criteria.

The software is ready for this. As for training a new defect model, it depends on how much data you have.

[50:46] If you have a new defect and a few dozen images, that’s already enough for the software to recognize it next time. If we see hundreds or thousands of examples, the software learns and integrates it fully into the analysis.

[51:22] Nic, would you like to answer this question? In case study number one, defects were mainly microcracks. How about performance accuracy for defects related to higher severity, such as cold soldering, over-soldering, or cell efficiency mismatch?

[52:27] Our software can handle a wide variety of cell-inherent defects. Microcracks are the most prominent ones and the main subject of this webinar, but we can detect over 15 different defect types.

This includes cell efficiency mismatch, finger interruptions, solder defects, and others.

[53:09] Over the years, we’ve accumulated a very large amount of EL images—over ten years’ worth. Some defects that were common years ago are now rare, while new defects, such as small MBB cracks, have emerged.

We continuously adapt to this.

[53:49] To summarize, yes—the system can address a wide variety of defects, currently about 15 types. There was another question from David. I believe I know which David this is—nice to have you on the webinar. We should catch up one of these days.

[54:28] He asked about EL images from flash tests. It’s not exactly the flash test—although flash tests are often IV tests—but rather EL equipment at the factory.

Have you considered the requirements for EL imaging to get the best image quality for analysis, such as power source settings and camera quality?

[55:06] That’s a very good question. Yes, we have our own EL standard that includes requirements for resolution and image file size. The reason is to set a minimum quality baseline.

Most major manufacturers have good equipment that produces high-resolution, non-blurry images, which helps detection.

[55:39] We’ve also trained the software on lower-quality images so it can still detect defects even when image quality is not ideal.

Better image quality always helps, but the software is robust enough to handle variation.

[56:18] Another question is about cost. As mentioned, we offer a free trial. If you’re working on a project this year, feel free to get in touch. Costs depend on project size. We’ll ask some questions, set up a call, and prepare an offer with full transparency.

[58:47] This is a very cost-effective way to assure quality. There is no other way to inspect 100% of modules so efficiently. There are still a few more questions. Greg had some connection issues—sorry about that—but he will follow up.

[59:39] David asked about defect grading standards: critical, major, minor, or ABCD. Most factories use critical/major/minor, and it’s best to align with factory methodology so everyone speaks the same language.

MBJ is an older standard that we don’t see much anymore.

[01:00:25} I believe we’ve covered most questions. If we missed any, we’ll follow up by email.

Thank you very much for attending. If you’re working on a project, feel free to reach out—we’d be happy to offer a free trial.

[01:01:08] We hope this was interesting for you, and we look forward to seeing you at one of our upcoming webinars. Bye for now. Good day. Visit sinovoltaics.com to learn more.