Organic Solar cells

Organic solar cells are one of the promising new cell technologies.

Currently organic solar cells have reached an efficiency of only 10%, and researchers expect it to increase to 15% in the coming 3 to 5 years. Efficiency is lower than standard silicon solar cells when measured under Standard Testing Conditions (STC), however there are major advantages compared to Silicon (Si) cell technology:

Advantages organic solar cells

Organic solar cells carry several advantages, including the following:

- Low cost materials, the materials used in organic solar cells have low production costs when produced on a large scale.

- Temperature resistance, temperature increases do barely affect the efficiency of organic solar cells, which means organic solar cells have the same performance during hot weather. As you probably know, silicon solar cells show a 0.5% drop in output for every degree in temperature increase above 25C, which leads to large performance losses.

- Light absorbance. On top of that, organic solar cells absorb de-fractioned light (just like thin films), which means the organic cells perform already during the early and late hours of the day. Silicon solar cells work best with direct sunlight only.

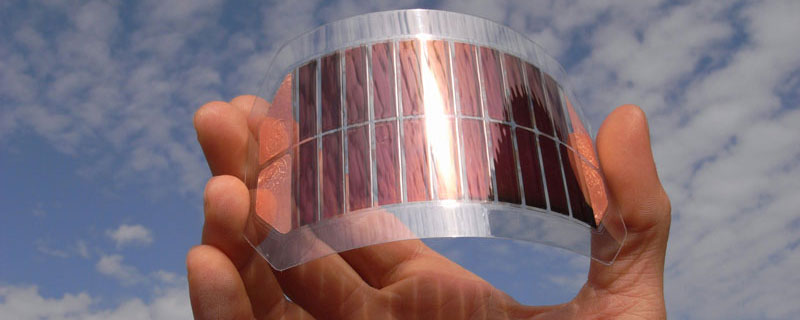

Organic flexible solar cells

Concerns organic solar cells

To benefit from the potential advantages of organic solar cells, research will need to overcome a few challenges. These are main ones:

- Lifetime organic solar cells. The main concern for organic solar cells is the lifetime. Currently lifetime is only around 6 years, which is not enough to compete with current mainstream cell technologies.

To improve the lifetime and reliability of organic cells, research team need to make several advances, including: - Encapsulation. Like any solar cells, organic solar cells need to be encapsulated. Most pv modules are encapsulated through lamination (EVA, TPT and glass), but a lighter weight solution would be plausible.

- UV protection.Besides the encapsulation, the organic solar cells will need a UV filter. Any organic material contains carbon, which will degrade. Instead of a UV filter, glass as the front protector can be used, which will catch most of the light.

Solutions from LED industry

Current problems with organic solar cells are quite similar to problems that were solved in the organic Light Emitting Diod (LED) industry. The solar industry can now borrow lots of technology from the LED industry and therefore people are confident that organic solar cells will overcome its current challenges, just as they solved the problems with LED lights in the early stages of its industry.

It is expected that organic solar cells will be stable in the future, the lifetime will increase, and that the efficiency will increase to up to 15%. In combination with the cheap material costs, this is a cell technology with the potential to go mainstream.

Dye Sensitized Solar Cells

Dye sensitized solar cells are closely related to organic solar cells, and belong to the thin films. This cell technology is currently amongst the most efficient third generation solar cells. With an efficiency of around 11%, and low cost production, this technology has the potential to compete on the commercial market.

Advantages dye sensitized solar cells

The dye sensitized solar cells has a number of advantages:

- Ease of production. Dye sensitized solar cells are simple to make using conventional roll-printing techniques.

- Flexibility. Dye sensitized solar cells are semi-flexible and semi-transparent, which opens up application that are impossible to cover with glass-made pv modules.

- Low cost. Most of the materials used are low-cost. Most of them.

Disadvantages dye sensitized solar cells

- Few expensive materials. Like mentioned above, most materials used to produce a dye sensitized solar cell are low cost. However researchers have so far not been able to eliminate some expensive materials, including Platinum and Ruthenium.

- Different weather conditions. The liquid electrolyte presents a challenge to making the solar cells suitable for use in all weather conditions. When installed in low temperature conditions, the electrolyte can freeze, which will stop power production and will potentially lead to damage. Higher temperatures cause the liquid to expand, making the encapsulation of the panels a serious problem.

- Conversion efficiency. The current conversion efficiency of dye sensitized solar cells is less than the best thin film cells. However due to the low manufacturing costs, the price / performance ratio is good enough for large scale power plants to compete with most fossil fuels in terms of pricing, including coal.

There are multiple companies working on dye sensitized solar cells, and a number of them are announcing to launch these cells as a commercial product. Companies working on dye sensitized solar cells include Solaronix, Dyesol, SolarPrint and G24innovations.