Operations & Maintenance of BESS: Ensuring Long-Term Performance

Introduction

Proper operations and maintenance (O&M) of a Battery Energy Storage System (BESS) is essential to ensure optimal performance, longevity, and safety. A well-maintained BESS can maximize energy efficiency, reduce downtime, and extend battery life, ultimately improving return on investment. This guide outlines the key O&M strategies for keeping a BESS in peak condition.

1. Routine Monitoring and Performance Tracking

Continuous monitoring helps detect potential issues early, preventing unexpected failures.

Key Performance Indicators (KPIs) to Monitor:

- State of Charge (SoC): Ensures batteries maintain an optimal charge level.

- Depth of Discharge (DoD): Prevents excessive battery wear by keeping DoD within recommended limits.

- Round-Trip Efficiency: Measures energy loss between charging and discharging.

- Battery Temperature: Avoids overheating, which can degrade performance and safety.

- Cell Voltage Balancing: Ensures all battery cells operate at similar voltages for uniform aging.

Best Practice: Use a monitoring solution like volytica diagnostics, Accure or Twaice for real-time performance tracking.

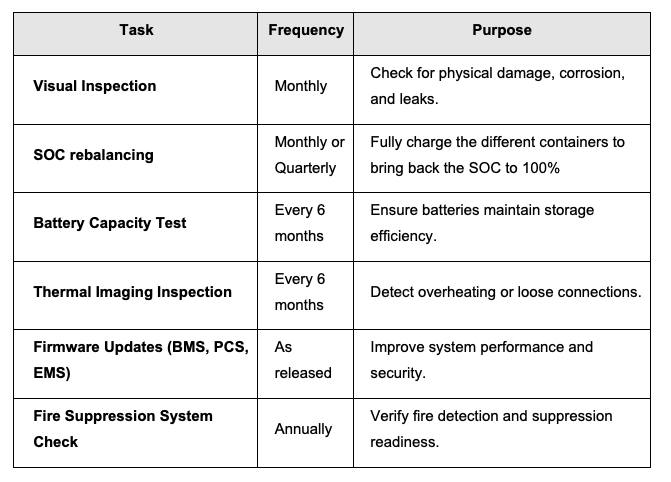

2. Preventive Maintenance Schedule

A structured maintenance plan prevents unexpected failures and extends battery lifespan. Best Practice: Follow manufacturer-recommended maintenance schedules and log all maintenance activities for future reference.

Best Practice: Follow manufacturer-recommended maintenance schedules and log all maintenance activities for future reference.

3. Troubleshooting Common BESS Issues

Identifying and resolving common BESS issues ensures continuous operation.

Common Problems & Solutions:

• Unbalanced Battery Cells

o Cause: Aging differences between cells.

o Solution: Perform BMS calibration and cell balancing.

• High Operating Temperature

o Cause: Inadequate cooling or ventilation.

o Solution: Check HVAC system and ensure airflow is unobstructed.

• Reduced Energy Storage Capacity

o Cause: Excessive cycling or aging.

o Solution: Limit Depth of Discharge (DoD) to manufacturer’s recommendation.

• Communication Failure Between Components

o Cause: Software glitches or faulty connections.

o Solution: Update firmware and inspect communication wiring.

• For any alarm, we strongly recommend contacting the manufacturer to double check if there is any specific troubleshooting process to follow.

Best Practice: Train maintenance personnel on rapid troubleshooting techniques to minimize downtime.

4. Battery Health Management

Proper battery health management ensures the BESS operates safely and efficiently.

Key Strategies:

• Maintain consistent charge/discharge cycles to avoid deep discharge damage.

• Keep batteries within optimal temperature ranges (typically 15-30°C).

• Avoid overcharging, which can cause thermal runaway.

• Use smart charging algorithms to extend battery lifespan.

Best Practice: Perform battery capacity tests every six months to assess health and detect early degradation. Our BESSential service can help.

5. Emergency Response and Safety Protocols

A well-prepared emergency response plan minimizes risks in case of system failures.

Safety Procedures:

• Fire Detection & Suppression: Ensure automatic fire suppression systems are functional.

• Emergency Shutdown Protocol: Define clear steps for shutting down the BESS in a failure scenario.

• Personnel Training: Regular safety training on handling thermal runaway, electrical faults, and ventilation failures.

Best Practice: Conduct quarterly safety drills and ensure fire department coordination for rapid response.

6. Long-Term System Optimization

BESS performance optimization strategies ensure maximum efficiency and cost savings.

Optimization Techniques:

• Peak Load Shifting: Charge batteries during low-cost hours and discharge during peak demand.

• Grid Services Participation: Leverage frequency regulation and demand response programs for additional revenue.

• Predictive Analytics: Use AI-based analytics to forecast performance trends and preemptively address issues.

Best Practice: Regularly update operating strategies to align with energy market trends and regulatory changes.

Conclusion

Effective BESS operations and maintenance enhance system longevity, efficiency, and reliability. By implementing routine monitoring, preventive maintenance, troubleshooting procedures, safety protocols, and optimization strategies, asset owners can ensure long-term performance and profitability.

Looking to optimize your energy storage system? Contact us today to speak with our experts and discover how we can support your BESS operations.