In our previous article about the basic features and available technologies for PV system monitoring, we spoke about the main parameters to monitor the performance of a PV system.

Building on this basic introduction to PV monitoring, we explain in this article the major types of solar panel meters required throughout the different stages of a common solar energy project.

Solar energy project phases

Solar energy projects can range from small kilowatt roof-top systems to large megawatt utility-scale farms. Even though varying in size – small, medium, and large – they can usually be broken down into three rough phases:

- Planning

- Installation and commission

- Operation and maintenance

The aforementioned phase structure can be further split and refined into steps such as financing, project site acquisition, system design, equipment supply sourcing, equipment production, logistics, and quality assurance.

The extent, workload, costs, and economic risks of these phases are largely proportional to the size of a project. During each phase, different types of measurement equipment are needed to ensure proper project setup. Solar panel meters are used to mitigate technical risks and ensure good returns of investment (RoI).

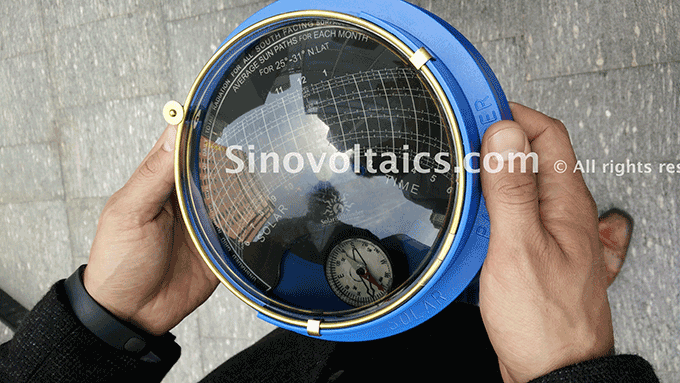

Solar Pathfinder – a bit old-fashioned but still used by many to register the path of the sun

Common solar panel meters

What types of meters are needed during these phases? Here is a general, though not exhaustive list:

- Pyranometers

- Solar Pathfinders

- Solar Simulators and Solar Analyzers

- Voltmeters, ammeters, power meters (DC and AC)

- I-V curve tracers

- Thermal imaging cameras

During which phase of a project are these solar panel meters used and how? Let’s have a look:

The Pyranometer

This is probably the first meter to be used when planning a solar energy installation, whether photovoltaic (PV), concentrated photovoltaic (CPV), or solar thermal.

The pyranometer measures the total solar insolence or solar radiation incident at a point on the earth’s surface. It measures the energy density available at the proposed site.

Based on the findings of the measurement, it is possible to estimate the panel area required for a given amount of power production or the power expected from a given number of panels. In case the planning and installation are done through a contractor, it is the contractor who will need this.

Solar Pathfinder

The shading assessment is part of the solar site analysis. The tool is popular with solar panel installers and can be used worldwide.

It will show exactly where the sun will travel throughout the year. It can help to determine which location is suitable to install solar panels, as it shows you how much shading you can expect over the course of the day. It measures and shows data not just during the day when you perform the measurement, but during any day/season.

Solar Simulators

A solar simulator, or: sun simulator, is a lamp device that simulates the radiation effect of the sun. It is designed to provide radiation approximating natural radiation. The purpose is to be able to carry out tests on panels, screens, and other devices inside a lab.

System monitoring: voltmeters, ammeters, A-H counters, and power meters

These solar panel meters are required when monitoring the system, for fault isolation and rectification. While a voltmeter is used to measure the voltage, an ammeter is used to measure the current.

The current capability will be according to the capacity of the installation. For DC meters the voltage can be up to 30 volts. Meters can be fixed and portable.

Clamp meters are useful for measuring current without breaking a circuit. A-H counters keep a record of how much battery capacity has been utilized, and how much balance could be expected.

Solar DC Clamp meter Fluke 337

Solar Analyser, I-V Curve tracer

The name may suggest that this instrument will analyze solar radiation. Actually, it analyzes mainly the photovoltaic panels and the system tie-up.

It treats the solar panel as an electrical device and measures its parameters, mainly open circuit voltage, short circuit current, and the I-V relations at various current levels.

These three parameters are good indicators of the health of a panel as a whole. For defects within a panel, infrared cameras may be more useful.

IR Imaging Camera

Sons of the same two parents are different. So are the solar cells produced in the same batch by the same equipment! Cells are connected in series-parallel arrangements.

Common quality issues with panels in installations involve loose connections as well as short circuits that can develop into hot spots, rendering the affected cell defective. If one or more cells become defective, they can mar the performance of the string it is assembled in and consequently of the whole panel.

The best way to locate such cells troubled by hot spots is IR imaging because they will have higher temperatures than the other cells.

AC Energy Meter

In the case of a private installation hoping to feed power to the grid, the energy meter has to be able to measure power two-way, because the installation may sell power to the grid.

There are two major mechanisms for selling to the grid. Net-metering records the ‘net’ energy consumed by the consumer, running forward when consuming and backward when supplying.

A Feed-in Tariff System accounts separately for the power supplied by the consumer. In case analog meters are used (one may be already installed), a separate meter is required to record the feed-in energy, and generally, a different tariff is fixed.

Digital designs are very flexible and should be able to show separate records of power drawn from the and power supplied to it.

Data Logger

As an optional monitoring system, a data logger may be installed. The data available can provide information on generation and usage patterns, and fault data for event analysis and future planning.

Magzoub

on 14 Oct 2016