Even though Bifacial solar cells have been around since the 1960’s, the commercial usage of these solar cells in pv projects is something relatively new. In the past, the double sided solar cells did not make any sense in terms of costs, however this has been gradually changing.

With the introduction of cost effective bi-facial cell manufacturing, the applications for are now emerging from BIPV projects to even utility scale.

What are Bifacial solar cells?

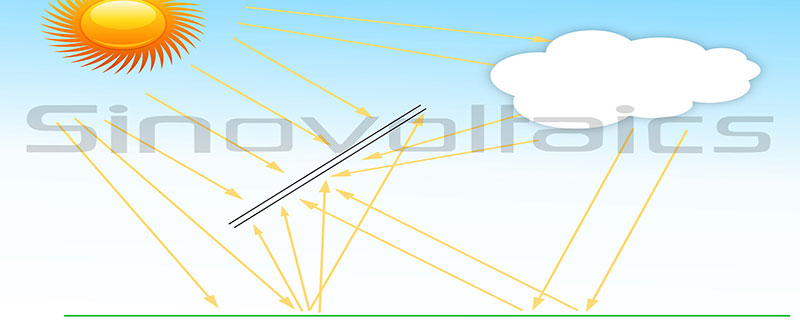

Bifacial solar cells are light-sensitive on both sides, and usually fabricated with mono crystalline cell technology. The efficiency is usually similar for each side of the cell, and the increase of energy output attains to >22% cell of equivalent efficiency.

For solar panels installed on the ground or on trackers, the cells catch the light that is reflected from the ground. When installed vertically, it catches the light on each side, when the sun moves from east to west.

Applications

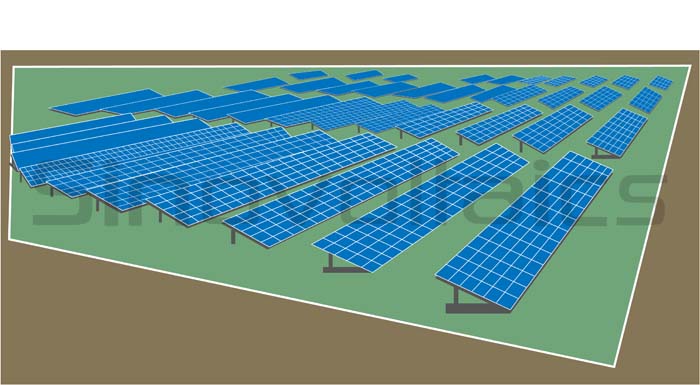

Ground installations

When looking at the economics, we’re close to using Bifacial cells for large scale ground installations. By allowing the light to reflect from the ground, an increase in power generation between 10 to 30% compared to traditional modules can be achieved.

The ground can be treated with reflective, white paints or other materials to increase reflection of the sun.

Noise Barriers

Solar cells can easily be installed in noise barriers along roads and railroad tracks.

The vertical mounting of such a barrier requires fewer space than normal south facing pv installations that require to be installed in a certain angle.

In case the bifacial solar cells are installed vertically, they’re optimally installed in a north-south direction, (with sunlight from the east and west). Installed this way, the bifacial cells can achieve nearly the same yield as solar systems that are facing south.

Solar trackers

The high support structures of polar axis solar trackers are very suitable to be used in combination with bifacial solar cells. As there’s plenty of space underneath the solar panels, there’s room for sunlight to reflect and reach the backside of the solar cells.

Energy collection with polar axis solar trackers is higher when compared to fixed pv arrays. Further the air cooling of the modules is better in comparison with pv installations mounted closely to a structure, which leads to less losses.

Space

Bifacial solar cells have been used in space since the 1970’s. The higher power/weight ratio has been the main advantage for the usage in space, and obviously the costs of the cells did not play a role for space projects.

During this time it was already shown that bifacial cells absorb less infrared light, which results in lower operating temperatures, leading to better performance. An increase of 10-20% efficiency has been recorded compared to mono-facial solar cells.

There’s a large number of other applications for bifacial cells, think about balconies, bus shelters, porch coverings, canopies, carports, facades, fences and so on.

Now developments in BIPV components are picking up at the moment, so it will be interesting to see if alternative solutions will emerge (such as building materials, with integrated solar cells), of if bifacial cells encapsulated between two pieces of glass will become the norm.

Costs

It’s not only the costs of the bifacial cells itself that determine if this technology is going to be used on a large scale. The costs for the complete solar modules need to be brought down.

Obviously an important requirement is that the pv module is transparent on both front and back. Most manufacturers of bifacial solar panels are laminating their solar panels using glass on both the front and back of the module.

Even though a slightly thinner glass of around 2mm, instead of 3.2mm can be used for double-glass modules, disadvantage remains that glass is expensive and heavy. You can not underestimate the extra costs involved when installing extra heavy solar panels, leading to increased logistics and labour costs.

An alternative is to use a transparent TPT film. However the transmissivity of this type of backsheet is not as good as glass, and is not as UV resistant.

Advantages

More flexibility in system design

The direction that the cells are facing is with the use of bifacial cells of less importance. Therefore there are less limitations in module applications and its design.

Vertical installation

By installing pv modules vertically, heavy snow loads or sand will not prevent the pv modules from generating power.

Disadvantages

So far the Bifacial pv modules that I’ve seen are made of double glass. The double glass adds significantly to the cost of the pv module. On top of that, it makes the module a lot more heavier.

Manufacturers

Some of the current bifacial PV module and/or manufacturers include Sanyo, Hitachi, B-Solar, and Prism Solar. They use various cell concepts such as HIT bifacial solar cell, p or n-type bifacial solar cells.

The construction is similar but not the same, leading to differences in performance and appearance. Nevertheless, all of these manufacturers use double side transparent encapsulation.

Sanyo

Sanyo produces the HIT double bifacial solar panel, which is a double glass module. It’s HIT solar cells (Heterojunction with Intrinsic Thin Layer) are composed of a thin single crystalline Si wafer, sandwhiched by ultra-thin a-Si layers.

Prismsolar

Prism manufacturers interesting bifacial modules. One module is a standard double glass, frameless module with bifacial solar cells. The second module is their holographic bifacial module, that combines highly efficient bifacial cells with Prism’s patented holographic technology.

Prismsolar holographic technology is described as following:

“These glass-on-glass holographic modules alternate strips of bifacial solar cells with parallel strips of holographic film. Where light hits the solar cells directly, it is converted to electricity as normal. Where light hits the holographic film, the hologram diffracts the light, and selects the most optimum portions of the spectrum for additional energy harvesting. The selected light is then channeled through the glass to the cells — thanks to a natural property of the glass known as “total internal reflection” — where the light is converted into additional energy. This selection and redirection of the optimal portion of the sunlight to bifacial solar cells generates up to 30% more kilowatt hours per watt of silicon when compared to traditional solar modules.”

B Solar

B Solar produces Bi-Facial solar cells (mono) and modules in Germany.