Validate Conforming Cable Design & Performance

Our PV cable and wire-specialized quality engineering team diligently oversees an extensive

array of final acceptance tests and inspections on cable samples, meticulously scrutinizing the manufacturer's Factory Acceptance Tests (FAT) documentation.

Rest easy knowing that you will receive a comprehensive witnessing report of the Factory Acceptance Tests (FAT), providing you with the utmost assurance of the impeccable quality performance of your cables. The respective sampling levels will be applied with ISO 2859-1:1999, G-1 per container of cables.

Pre-shipment final acceptance tests include:

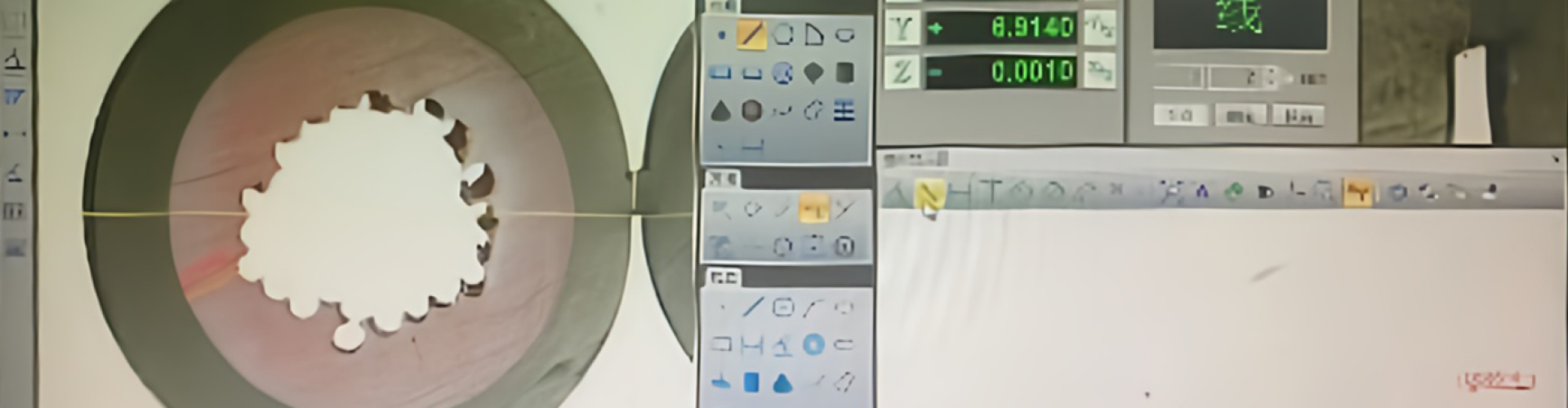

- Cable dimensions and markings conformity

- Conductor resistance test

- Tensile strength test

- Insulation layer thickness compliance

- Dielectric strength and climatic stress

- Splitting and crimping test

Some of the PV Cable factories where our inspection team has been active:

- Exeltech

- FRCable

- JOCA

- SNH Cable

- Xinhongye