Looking at our solar module quality inspection data of the past 12 months, there’s one solar module defect that stands out.

Our quality engineers found major micro cracks in 53.6% of inspected solar module orders.

The #1 defect that affects PV plant ROI

The #1 defect that can affect your PV plant performance are cell inherent defects, including micro cracks.

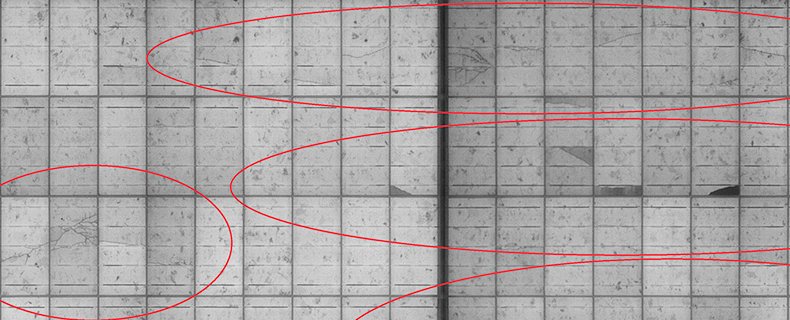

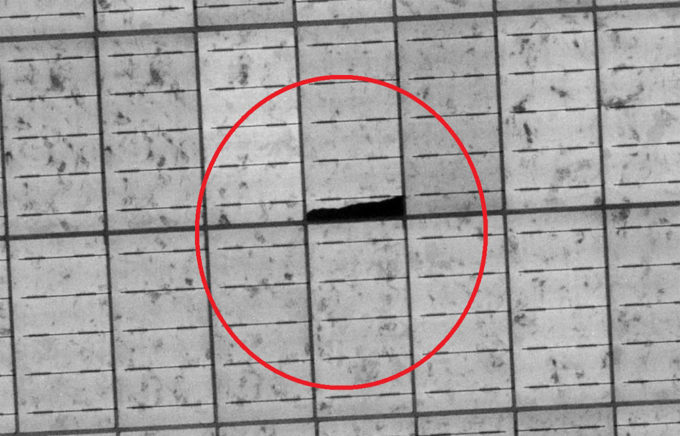

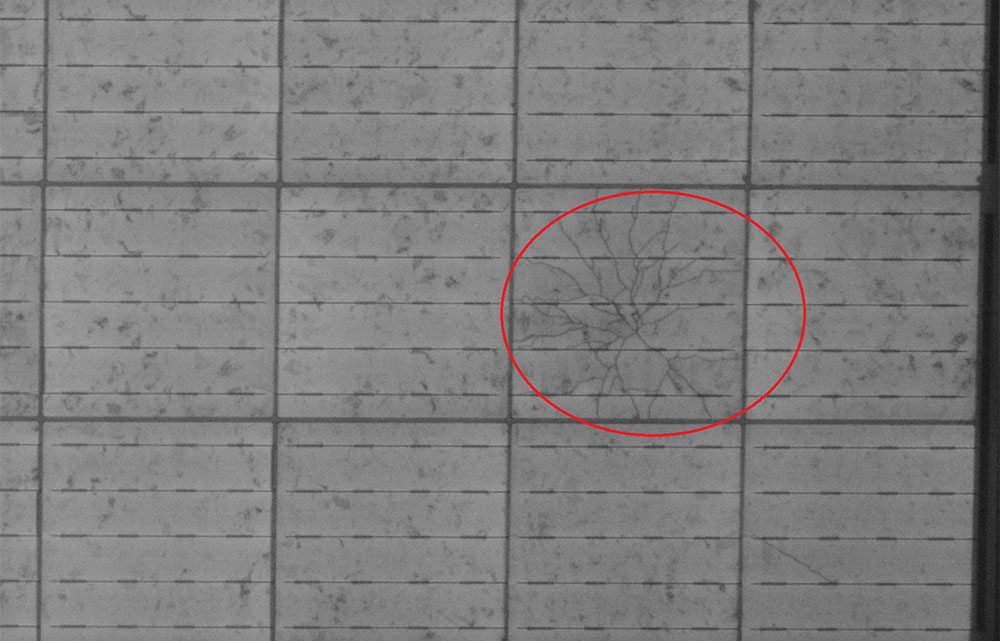

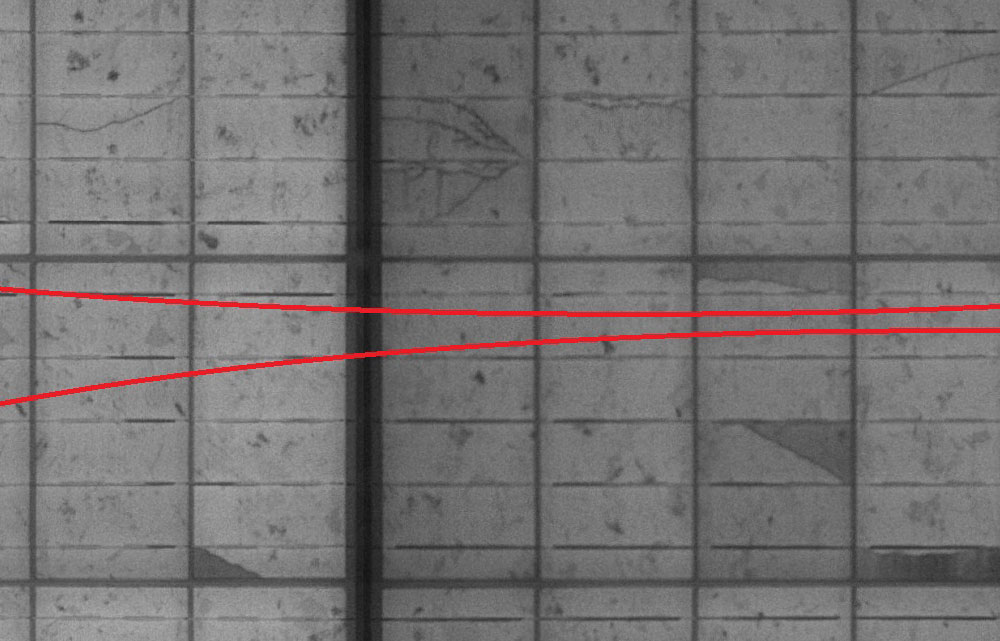

Some examples of the past weeks:

A single crack in a module with half cut cells can easily turn part of the cell inactive. This defect affects the power output of the entire string, and therefore the entire module. Such a defect results in a reject and the solar module is replaced.

Branched micro cracks are amongst the worst. This affected solar cell brings down the power of the module, and consequently the power output of the entire module string once installed. Typically such defects occur during handling, or walking on the solar module. A factory that OK’s such cracks should not be producing solar modules, however we unfortunately spot such cracks on a weekly basis.

This module with half cut cells has a variety of micro cracks, including single cracks that cause inactive cell area, branched cracks and cell piercing cracks. The cracks in such a module will inevitable get worse over time. The Power output at the time of IV testing the solar module at the factory was according to label rating. However… of course this module was a clear reject.Such a module will degrade quickly in the field and would’ve brought the power production down.

How to avoid Micro Cracks in your shipments?

The good news is: micro cracks can be easily avoid…

and they should be, as they’re the number #1 defect that affects your pv project ROI!

Two key steps to take:

- Include a strict EL quality standard in your purchase contractAgree with your PV manufacturer on a strict EL standard. Each PV manufacturer has its own EL standard, and most EL standards are not strict at all. If you don’t contractually agree on a strict quality standard with your pv manufacturer, the factory is contractually able to supply you with modules that are full with cracks. We see this happening every day at the factories in Asia.Reply this email or contact us to start using our Quality Standards in your Purchase Contract.

- Review 100% of EL images before your solar modules are shipped.100%? But what happened to sampling? ..We say, no more sampling when it comes to micro cracks! Over the past 3 years, Sinovoltaics has developed proprietary software to review 100% of solar modules on cell inherent defects and eliminate all major micro cracks before your solar modules are shipped. This way you’re sure that, as soon as your solar modules leave the factory, your solar modules are defect free.

Don’t take our word for it! Companies such as Fortum, juwi and MunichRe are using our services to eliminate risk from their projects.

Contact us and learn how also you can eliminate micro cracks from PV purchases.