Battery Cell Chemistry in BESS: LFP vs. NMC – Which Is Better?

Introduction

Choosing the right lithium-ion battery chemistry is a critical decision in Battery Energy Storage System (BESS) design. The two most common lithium-ion chemistries used in energy storage are Lithium Iron Phosphate (LFP) and Nickel Manganese Cobalt (NMC). Each has distinct advantages and trade-offs in terms of safety, lifespan, cost, and performance.

This guide compares LFP and NMC batteries to help determine which chemistry best suits your energy storage needs.

1. Overview of LFP and NMC Battery Chemistries

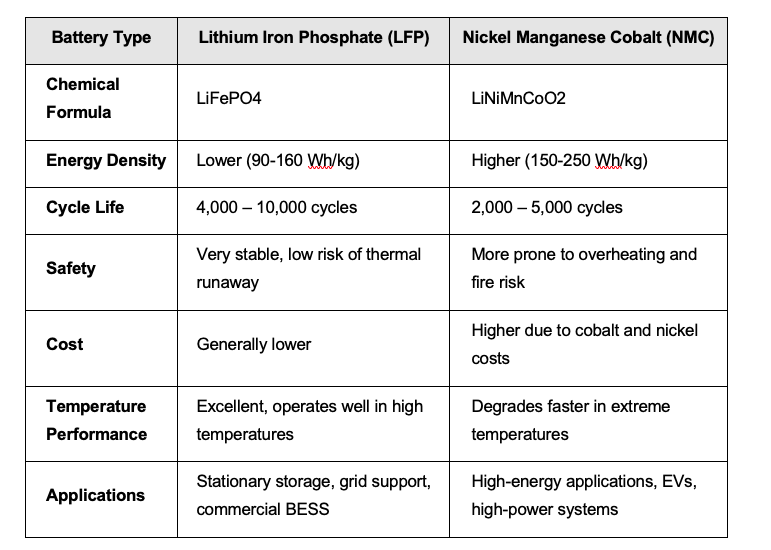

Each chemistry has its strengths, making it important to select the best fit based on application and operational requirements.

2. Energy Density: NMC Offers Higher Storage Capacity

Energy density refers to the amount of energy stored per unit weight.

• NMC batteries have a higher energy density (150-250 Wh/kg), making them ideal for applications requiring compact and lightweight storage, such as electric vehicles.

• LFP batteries have a lower energy density (90-160 Wh/kg), which means they require larger and heavier battery packs for the same energy storage.

Key Takeaway: If space is a constraint and a high-energy output is required, NMC may be the better choice. However, for stationary BESS where size is less of a concern, LFP remains a viable option.

3. Cycle Life Comparison: LFP vs. NMC Batteries in BESS

Cycle life is the number of charge-discharge cycles a battery can undergo before degrading.

• LFP batteries typically last 4,000 – 10,000 cycles before reaching 80 percent capacity.

• NMC batteries degrade faster, offering around 2,000 – 5,000 cycles.

Key Takeaway: LFP has a longer lifespan, making it more cost-effective for long-term stationary applications like grid storage.

4. Safety: LFP is More Stable

Battery safety is critical, especially in large-scale energy storage applications.

• LFP is inherently more stable and has a lower risk of thermal runaway or fire hazards.

• NMC contains cobalt, which can increase the likelihood of overheating and combustion, especially in high-temperature environments.

Key Takeaway: LFP is the safer option, particularly for grid-scale storage, commercial energy systems, and residential applications where fire risk must be minimized.

5. Cost: LFP is More Affordable

Battery cost is influenced by raw materials, manufacturing complexity, and supply chain stability.

• LFP is generally cheaper since it does not use expensive cobalt and nickel.

• NMC is more expensive due to reliance on nickel and cobalt, which are subject to supply chain volatility.

Key Takeaway: If cost is a major factor, LFP offers a lower total cost of ownership over the system’s lifetime.

6. Environmental Impact: LFP is More Sustainable

Sustainability is an increasing concern in energy storage technology.

• LFP batteries do not use cobalt or nickel, which are associated with ethical mining concerns and environmental damage.

• NMC requires cobalt, which has a higher environmental footprint and potential for supply chain disruptions.

Key Takeaway: LFP is a more environmentally friendly option, making it preferable for sustainable energy projects.

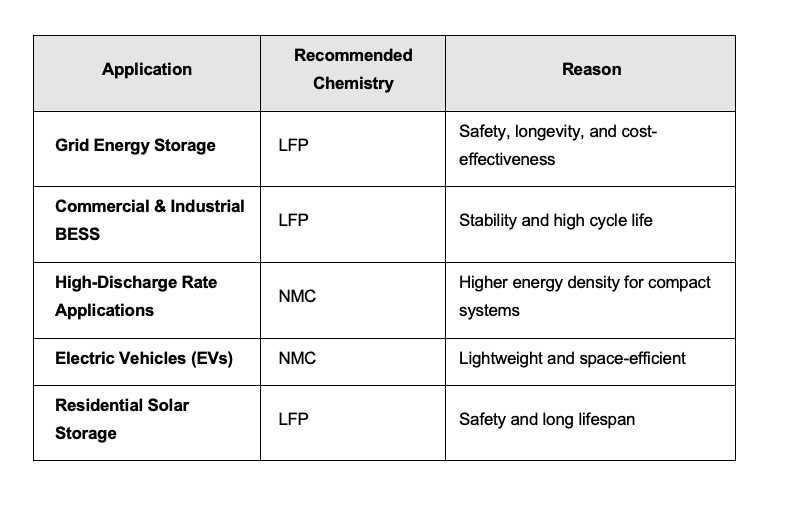

7. Best Applications for LFP vs. NMC Key Takeaway: LFP is preferred for stationary storage, while NMC is better suited for high-energy mobile applications like EVs.

Key Takeaway: LFP is preferred for stationary storage, while NMC is better suited for high-energy mobile applications like EVs.

Conclusion

Choosing between LFP and NMC batteries depends on specific project needs.

• LFP excels in safety, longevity, and cost-effectiveness, making it ideal for grid storage, commercial BESS, and renewable energy integration.

• NMC offers higher energy density but comes at a higher cost and with increased safety risks, making it more suitable for EVs and space-constrained applications.

For most stationary battery energy storage systems (BESS), LFP is the best battery for energy storage thanks to its safety, longevity, and lower cost. LFP is by far the most popular battery chemistry being used in BESS today.

Looking to determine the best battery chemistry for your energy storage project? Contact Sinovoltaics for expert guidance on LFP vs. NMC in BESS and ensure your system is optimized for safety, performance, and long-term ROI.