Solar Panel Lamination: procedure, advantages and disadvantages

Solar panel lamination is crucial to ensure the longevity of the solar cells of a module. As solar panels are exposed and subject to various climatic impact factors, the encapsulation of the solar cells through lamination is a crucial step in traditional solar PV module manufacturing.

Solar Panel Lamination

At this moment, the most common way to laminate a solar panel is by using a lamination machine. This old-fashioned method has many disadvantages but is used by the large majority of solar panel manufacturers.

How is a solar panel laminated?

PV lamination is a proven concept and works as follows: In order to laminate a solar panel, two layers of ethylene-vinyl acetate (EVA) are used in the following sequence: glass / EVA / solar cell strings / EVA / tedlar polyester tedlar (TPT).

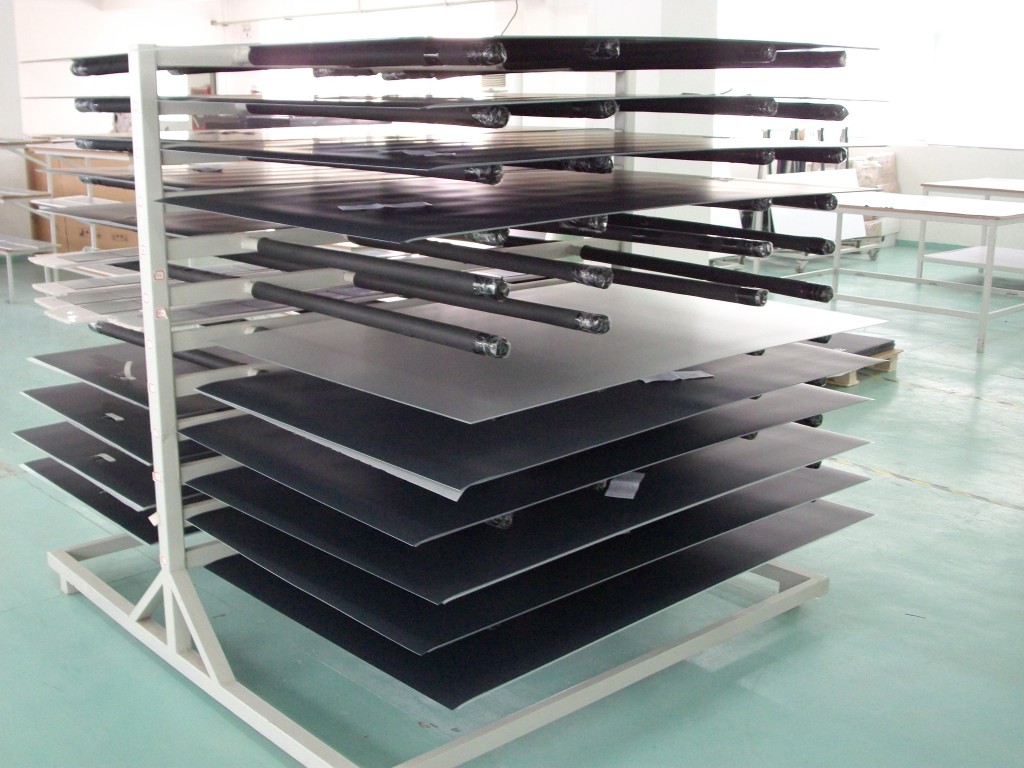

Ready for lamination.

During the lamination process, the prepared 5-layer module is placed in the lamination machine and heated to the max. 135°C for a period of approx. 22 minutes. The laminate that comes out is completely sealed, and when produced well, will protect the solar cells for at least 25 years. After the laminate is cooled down, excessive EVA and TPT will be cut away, and the junction box will be attached. Finally, the laminate can be framed.

Why is the current mainstream lamination process terribly outdated?

This way of laminating is a proven concept, but it has disadvantages: a lamination machine is large, expensive, and consumes much electricity. Moreover, a lamination machine is slow and is often considered as the PV module production bottleneck for any factory. A normal lamination machine can only produce 2 panels at a time, with a max. of 6/ hour. Imagine how all these MW's of panels are currently produced!

Solar panel laminator

Solar panel laminatorWhat is the future when it comes to PV lamination?

Nowadays there are numerous encapsulants that are most likely going to replace the old-fashioned way of laminating. A company that is a leader in innovation and has developed a new way of encapsulating solar panels is the Canadian manufacturer Qsolar (www.qsolar.net). Their Spraytek technology replaces the old-fashioned lamination process with a spray machine that equally spreads an adhesive on the solar panel. The major advantage of spray technology is that the solar cell are treated gently. During the old-fashioned lamination process, it's very common that solar cells crack. This is due to irregular soldering connections. With the use of innovative procedures such as Qsolar's Spraytek, this will not be an issue anymore.

Rachel Komyate

on 07 Dec 2021Kamlesh Sharma

on 21 Jun 2021HUSSAIN YOUSUF

on 27 Feb 2021