EVA (ethylene vinyl acetate) Film: composition and application

EVA is the abbreviation for ethylene vinyl acetate. EVA films are a key material used for traditional solar panel lamination.

What are ethylene vinyl acetate(EVA) films?

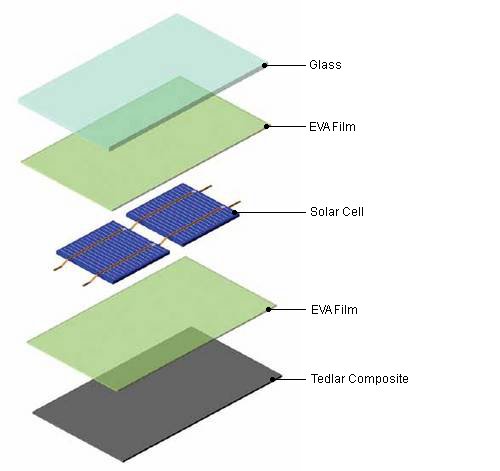

In the solar industry, the most common encapsulation is with cross-linkable ethylene vinyl acetate (EVA). With the help of a lamination machine, the cells are laminated between films of EVA in a vacuum, which is under compression. This procedure is conducted under temperatures of up to 150°C. One of the disadvantages of EVA films is that it is not UV-resistant and therefore protective front glass is required for the UV screening.

EVA film - solar cell encapsulation

EVA film - solar cell encapsulation

For standard modules that use EVA encapsulation, for the backing usually a layer of tedlar composite (tedlar polyester tedlar (TPT)) is used, which is a thin, opaque film. Tedlar is the Dupont tradename for a film of polyvinyl fluoride, PVF, poly ethylene terephthalaye (PET) or metal.

Long term encapsulation and protection

Once the EVA sheets have been laminated, the ethylene vinyl acetate sheets play an important role in preventing humidity and dirt penetrating the solar panels. Also with the help of the EVA, the solar cells 'are floating' between the glass and backsheet, helping to soften shocks and vibrations and therefore protecting the solar cells and its circuits.

EVA and TPT layer

EVA and TPT layer

Ethylene vinyl acetate (EVA) Properties

Durability

Quality EVA film is known for its excellent durability, also in difficult weather circumstances, such as high temperature and high humidity.Want to validate your EVA film choice or module encapsulation quality? Request a quote.

Bonding

Under the right circumstances, EVA film will have excellent adhesive bonding to solar glass (NOT standard glass, solar glass has a rough surface). Also EVA bonds very well to the backsheet.

Optical

EVA is known for its excellent transparency. This means that the optical transmission is acceptable and doesn't block too much of the sunshine trying to reach the solar cells. Nowadays, several manufacturers in Asia use a transparent backing, which has transparency between the cells as a result. This type of module is known as semi-transparent.