Solar Glass: applications and comparison to Light-Trapping

Solar Glass is one of the crucial barriers of traditional solar panels protecting solar cells against harmful external factors, such as water, vapor, and dirt.

For what type of solar panels is glass used?

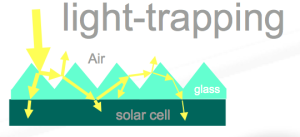

Solar light trapping Source: Saint Gobain

Solar light trapping Source: Saint Gobain

- Thin film solar panels For the substrate of a thin film panel often standard glass is used, simply because it's cheap. The superstrate cover glass has higher requirements. The cover glass needs to offer low reflection, high transmissivity, and high strength.

- Crystalline silicon solar panels Typically a 3.2mm thick piece of solar glass is used. The solar glass has a rough surface. This is needed, because, during the lamination process, EVA needs to adhere to the glass. The completely smooth glass wouldn't adhere well and would lead to de-lamination.

- Concentrated Photovoltaics (CPV) Lenses are often made of polymer as well.

- Solar thermal collectors.

What properties are expected from solar glass?

High solar radiance transmittance

The type of solar glass directly influences the amount of solar radiation that is being transmitted. To ensure high solar energy transmittance, glass with low iron oxide is typically used in solar panel manufacturing.

Strength

Solar panels are made of tempered glass, which is sometimes called toughened glass. There are specific properties that make tempered glass suitable for the manufacturing of solar panels. First of all tempered glass is much stronger than other types of glass. Secondly, tempered glass is considered safety glass. In case it breaks, it will shatter in thousands of small pieces, that won't be harmful. Both the strength and safety are important for the installation of solar panels.

Durability

Solar glass, as the front sheet of a pv module, needs to provide long-term protection against the elements. Glass is used because it's well known for its durability, even though it has disadvantages as well. What are the Disadvantages of solar glass?

Heavy weight

Typical solar panels are not easy to carry, because glass is heavy. A standard 250W c-Si solar panel is laminated on a 3.2mm thick piece of glass and weighs around 20kg. Many installers accept this heavy weight as it's currently the industry standard. However, there are several companies, such as the Canadian company Qsolar, that are working on ultra light weight solar panels.

Breakable

There's a good reason why a typical glass solar panel needs a 45mm frame. Glass by itself is not strong enough to meet the IEC / UL mechanical load strength requirements (2400pa). Tempered or not, glass is breakable. We have in many cases observed solar panels break during manufacturing (lamination) and have seen broken solar panels after shipping. At this moment glass is the most used material to give strength to a solar panels, however this might change in the future.

Broken tempered glass

Broken tempered glass

Are there any additional features for solar glass?

Anti-reflective (AR) coatings

An anti-reflective (AR) coating can be added to solar glass by plating one layer of anti-reflection film before the glass is tempered. The coating will improve transmittance by reducing the reflectance on the surface of the glass. The application of an AR coating on the glass surface can increase the share of sun irradiance effectively used for power generation by over 2.5 %. This corresponds to an increase of > 6 Wp for a module with a power rating of 250 Wp.

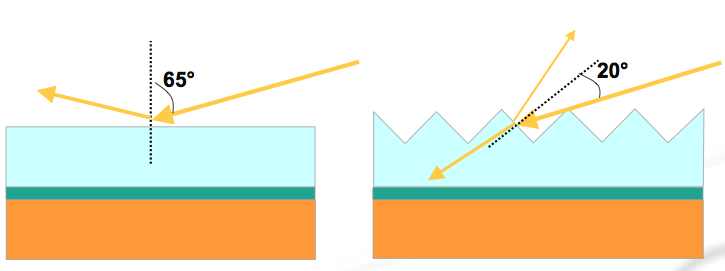

Standard solar glass (left) vs Light Trapping - Source: Saint Gobain

Standard solar glass (left) vs Light Trapping - Source: Saint Gobain

Light-Trapping

An alternative to an AR coating is Light-Trapping. A solar panel with this particular surface catches more solar radiation, mainly because not only direct sunlight reaches the solar cells, but also the less favorable, flat angle radiation is absorbed.