Thin-Film Modules

What are thin-film cells?

Thin-Film Photovoltaic Cells (TFPV), alternatively known as Thin-Film Solar Cells (TFSC), are - as opposed to wafer silicon (mono- and polycrsystalline) - cells made by depositing consecutive layers (thin films) of semiconductor material on substrates, such as ceramic, glass, metal or plastic. There are four major categories of photovoltaic materials used in this process, after which thin-film solar cells a generally categorized. These four major semiconductor materials are:

- Amorphous silicon (a-Si)

- Cadmium Telluride (CdTe)

- Copper indium gallium selenide (CIGS)

- Dye-sensitized solar cell (DSC)

As opposed to c-Si cells, the inter-cell connections of the whole module are made integrally during the deposition process and connected in series with the outer metal strip being the negative terminal and the outer transparent conductor strip the positive terminal for the whole thin-flim module. They are thus more stable and less failing than inter-cell connections of wafers that have to be placed individually (broken connections are not an uncommon finding during quality inspections). There is a variety of deposition techniques, including:

- chemical vapour deposition (CVD)

- electro-chemical deposition (ECD)

- physical vapour deposition (PVD)

- plasma enhanced chemical vapour deposition (PECVD)

Thin-film cells are laminated to make the later module more robust and resistant against weather or other environmental impacts. They can be produced either in single-junction or multi-junction configurations. While the single-junction configurations involve only one cell and only cover one part of the solar spectrum, the multi-junction configurations refer to combined sets of single thin-film cells. These use different parts of the spectrum from their respective angle to jointly convert the respective portions into electricity, thus using a much larger range of the input of sunrays.

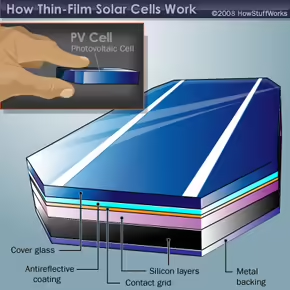

Composition of thin-film solar cell. Source: HowStuffWorks

Composition of thin-film solar cell. Source: HowStuffWorksAdvantages and disadvantages as compared to c-Si modules

Thin-film modules are thinner and much more flexible than the inelastic c-Si modules and can be easily applied on various types of shapes of facilities, such as round rooftops. Thin-film modules are also much more low-weight than their heavy counterparts and more resistant against environmental impacts, even allowing for walking on them. Thin film modules allow for higher yields per installed kW, especially under the condition of diffuse radiation. Disadvantages are their comparably lower efficiencies and higher production costs.