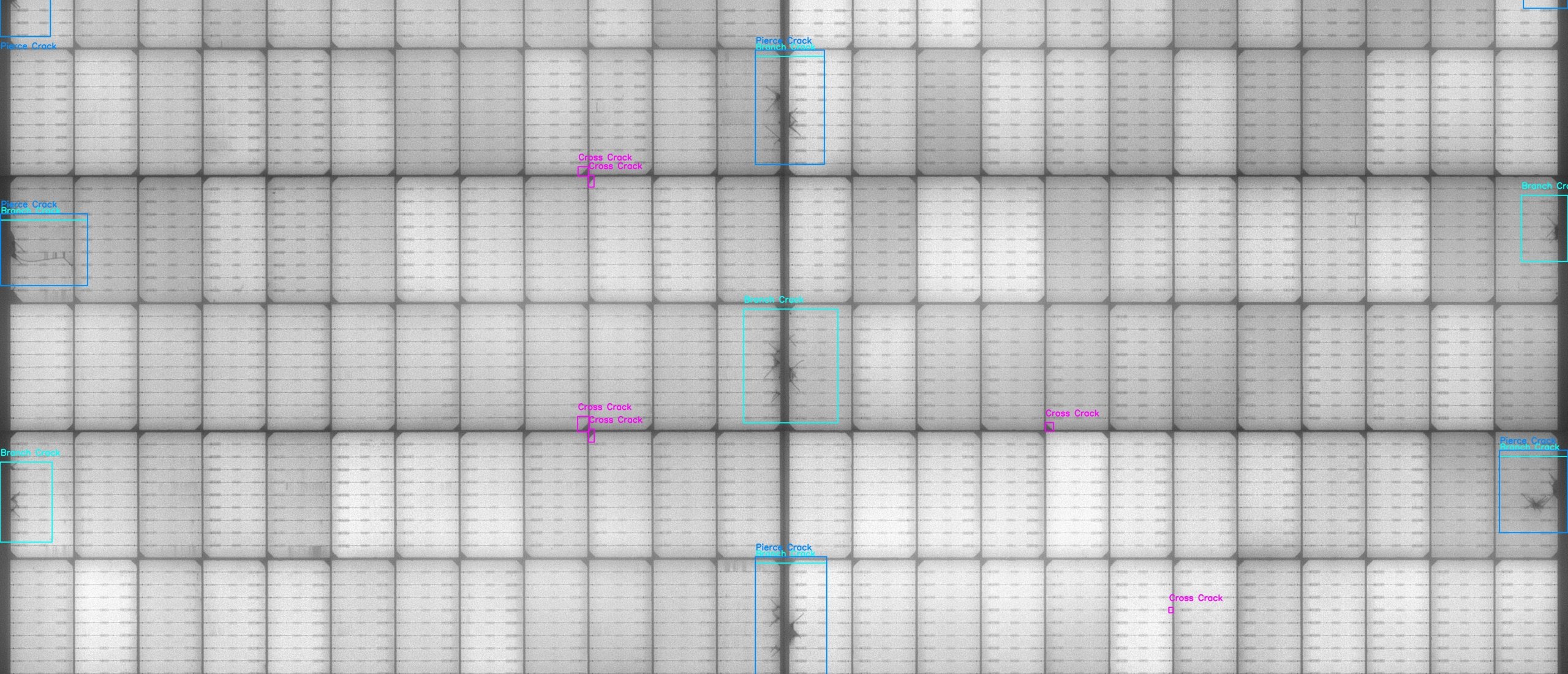

Typical Solar Panel Performance Degradation due to Micro Cracks

The performance degradation of solar modules due to micro cracks has been extensively studied, revealing a variety of impacts:

1. Reduction in Key Performance Parameters: Micro cracks act as additional recombination centers, reducing the short-circuit current density, open-circuit voltage, and the effective lifetime of carriers in solar cells, especially under Potential Induced Degradation (PID) conditions in PID solar panels. [1]

2. Significant Power Loss: Microcracks can lead to considerable power loss in PV modules, with some studies indicating losses as high as 60%, particularly when cracks form in parallel with the bus bars. These defects can also lead to thermal hot spots, which are potential fire hazards. [2]

3. Impact on Electrical Parameters: The presence of solar microcracks increases recombination current density in the depletion region of solar cells, adversely affecting parameters such as efficiency. [3]

4. Variability in Power Degradation: The exact impact of microcracks on solar module performance can vary. For example, a study found that the maximum power loss in certain PV modules with microcracks was up to 80.73%. [4]

5. Crack Propagation and Fatigue Degradation: In monocrystalline silicon cells within PV modules, crack propagation can occur, leading to fatigue degradation. This suggests the importance of reducing cyclic stresses to limit the effect of cracking. [5]

6. Thermal Mismatch and Hot Cells: Modules with high thermal mismatch (hot cells) show more significant power degradation, primarily due to fill factor degradation. Cracked cells that develop hot spots show higher power degradation in certain climatic conditions. [6]

In summary, microcracks significantly impact the electrical performance and longevity of solar modules, necessitating effective detection and mitigation strategies to ensure the reliability and efficiency of solar power systems. In the framework of its Zero Risk Solar approach to PV quality assurance, team Sinovoltaics performs 100% EL image analysis using its proprietary analysis software SELMA (Sinovoltaics EL Mass Analysis).

Sources:

1) Nguyen, Dong, et al. “Recover Possibilities of Potential Induced Degradation Caused by the Micro‐cracked Locations in P‐type Crystalline Silicon Solar Cells.” Progress in Photovoltaics: Research and Applications, vol. 423–432, no. 4, 4 Dec. 2020, https://doi.org/10.1002/pip.3383.

2) Teo, Teow Wee, et al. “Recent Advancements in Micro-crack Inspection of Crystalline Silicon Wafers and Solar Cells.” Measurement Science and Technology, vol. 081001, no. 8, 11 June 2020, https://doi.org/10.1088/1361-6501/ab8088.

3) (Pletzer et al., 2015).

4) Dhimish, Mahmoud, et al. “Effect of Micro Cracks on Photovoltaic Output Power: Case Study Based on Real Time Long Term Data Measurements.” Micro & Nano Letters, vol. 803–807, no. 10, 1 Oct. 2017, https://doi.org/10.1049/mnl.2017.0205.

5) Paggi, Marco, et al. “Fatigue Degradation and Electric Recovery in Silicon Solar Cells Embedded in Photovoltaic Modules.” Scientific Reports, vol. 4, no. 1, 28 Mar. 2014, https://doi.org/10.1038/srep04506.

6) Chattopadhyay, Shashwata, et al. “Correlating Infrared Thermography With Electrical Degradation of PV Modules Inspected in All-India Survey of Photovoltaic Module Reliability 2016.” IEEE Journal of Photovoltaics, vol. 1800–1808, no. 6, 1 Nov. 2018, https://doi.org/10.1109/jphotov.2018.2859780.