The purchase of solar panels in China is not only a question of good pricing, workmanship and output performance, but also increasingly of a PV module’s aesthetics. While most end-users still regard the issue of cell color deviations (abbreviated as CCDs) as a minor issue, some place high expectations regarding the outer appearance of their purchased panels, too, taking into account the necessity of the overall nice looks of their homes.

The solar PV module quality inspection company Sinovoltaics has over the years been witnessing these particular demands and incorporated additional inspection procedures to identify and counter CCDs. Following report stems from first-hand experiences.

Definition of Cell Color Deviations

CCD refers to panels suffering from deviating and differing cell colors within a given panel as well as diverging cell colors between two panels. The major reason for CCDs lies in the selection of non-coherently coloured cells during the manufacturing process as well as selection of low grade cells that have even deviating colouring within the cell itself.

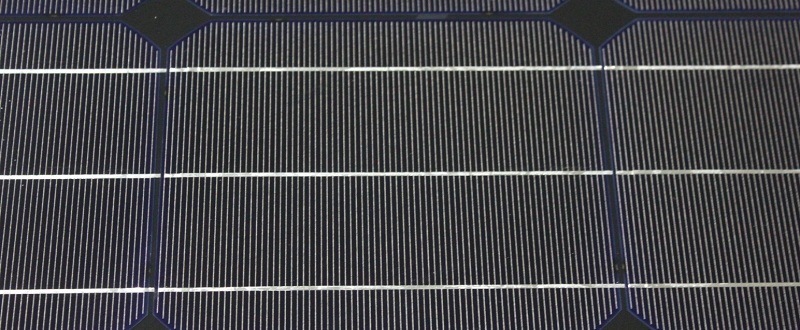

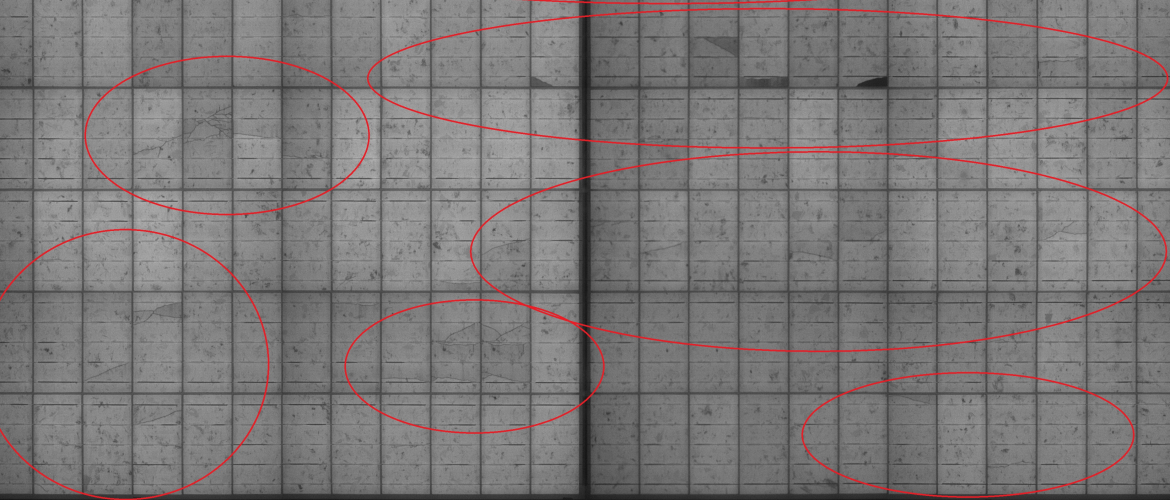

These types of CCDs can be seen in the following three examples (click to enlarge):

1. different cell colors within one sample module

2. cell with deviating coloring

3. different cell coloring between two sample modules of the same type

How to identify CCDs?

CCDs can optimally be identified under sunlight conditions. Based on a standard reference panel, the solar panels and cells subject to CCD checking must be put under these conditions and compared to the target reference cell color.

If no sunlight conditions are available, decent lighting conditions within the factory might as well do the job, too, however the availability of “real” sunlight outside the factory is the preferable condition for CCD checking.

Given these conditions, CCD checking not only requires much time, experience, familiarity with the reference cell color as well as good and trained eyes, but also established evaluation criteria to measure the severity of CCDs.

There is certainly a huge difference between minor, barely visible CCDs and CCDs that can be spotted even from 100m distance.

Since many manufacturers in Asia either do not know or if they know still care little about CCDs or lack trained staff/ ressources to track down CCDs and sort out CCDs-affected panels, an external auditor comes here in handy.

Problems occurring from CCDs

Although usually not an issue of efficiency or output performance, CCDs-affected solar systems do certainly not look beautiful. However, cell color deviations may well point to the usage of lower quality cells as well as solar cell procurement from various supply sources.

Many manufacturers, distributors and even end users do not pay much attention to the aesthetic aspect of their purchased solar modules and therefore quality management at many factories neglects this issue .

Rather, most focus on the main factors operational efficiency and overall performance. However, the issue of CCDs and their avoidance is increasingly becoming a primary issue manufacturers need to avoid and solar module quality auditors need to identify.

Pictures like these show how a solar system suffering from CCDs looks like on a private home:

Solar modules with differently colored cells

Outlook and development

With the ongoing price decreases of solar modules and increasing performance and also aesthetical quality requirements by a growing user base in mature solar markets, particularly in Europe and Oceania, but also in emerging solar markets in Southeast Asia, the successful avoidance of CCDs more and more becomes a strong selling point for caring manufacturers.

imran shaikh

on 22 Nov 2021