When thinking about the major development drivers in the solar PV module manufacturing industry, what would we usually come up with? A considerable focus lies on PV module production cost reduction.

Frequently reported and highlighted are also the ‘breathtaking’ efficiency increases of a manufacturer’s new super-dooper module by an enormous 0.123%…

But, what about performance quality, the minimization of power losses and in this regard the long-term ROI?

In this article, we will look at an increasing trend in the PV industry: smart module technology. In order to determine what makes a smart module smart, we will first need to understand what makes a conventional PV module ‘dumb’.

The traditional, ‘dumb’ PV module: what is it, and what solutions?

Standard solar photovoltaic (PV) systems consist of multiple modules connected in a string to an inverter. As the modules of a string are connected in series circuits, the overall performance of that string is geared to the individual performance of each module in the string.

Working together in a team, there can only be optimal output if all are working diligently and performing strongly, whereas weak, badly performing units can take down the overall performance of the whole module team. That said, the PV module with the lowest power output will take down the overall output of that string.

To counter such potential output performance problems, PV system plant developers have increasingly looked at using micro-inverters.

Micro-inverters handle one single panel or even two panels (dual micro-inverters). Similar to the larger traditional inverters, they convert the direct current (DC) electricity generated from that single (or two) module(s) into alternating current (AC) electricity.

Micro-inverters can directly tune the output of an individual panel by applying individual maximum power point tracking (MPPT) and in this way optimize the yield of the whole system.

When using modules cum micro-inverters, shading or manufacturing defects of single module parts or whole modules do in such installations not bring down the output of the whole string.

Moreover, micro-inverters offer distinct advantages in terms of lower heat loads, less wiring requirements, and overall system planning and component replacement flexibility.

However, the major disadvantage of micro-inverters though has been their considerably higher pricing. Team Sinovoltaics has in a previous article elaborated in more detail on the pros and cons of micro-inverters.

An increasingly hot technology trend in the PV industry is towards greater integration of solar modules and DC to DC converter technology in form of power optimization electronics without using separate components in form of micro-inverters that need to be sourced and combined. This integrated type of module-level power electronics (MLPE) is commonly referred to as a smart module.

Background: what are DC to DC converters?

DC to DC converters is what their name says. They convert DC at one voltage to DC at another voltage without using a conventional transformer.

In this process, they can provide voltage regulation and current limiting. Imagine a control mechanism draining a packet of charge from the input DC source, and then pouring it into an output reservoir, called: capacitor, from which charge is being drained by a load.

Output voltage level can be controlled through either the frequency of packet transfer (pulse frequency modulation) or the amount of charge per packet (pulse width modulation).

The capacitor ensures a more or less constant, ripple-free voltage level which could be higher than the input voltage (boost), or lower (buck) converter. Since the pulse frequency is in many kilohertz, we can use a small capacitor.

The ‘packet’ is normally captured in an inductor in the form of a magnetic field. The inductor size can also be small because of the high frequency.

The picture can now be restated. An inductor is allowed to charge (draw and build up current) from the input DC source, by an electronic switch – normally a field effect transistor (FET), in preference to bipolar junction transistors (BJT).

The switch is operated by very short pulses at many kilohertz. When the switch is toggled, the stored energy is coupled to the output. Because of Lenz’s Law, the output voltage can be higher than the input voltage.

DC to DC converter: components and applications

Essential components of a DC-DC converter area processor/ controller are:

- a single inductor or, in some configurations, two coupled inductors – not exactly a transformer used in AC

- semiconductor switch

- filter capacitor

- other minor components

No transformer is used. Because of the high-frequency small inductors and capacitors can be used, and hence, DC-DC converters are lightweight. They are more efficient compared to linear regulators.

DC-DC converters have wide applications. Most portable electronic equipment will use DC-DC conversion to obtain its working voltages.

In the context of solar energy, the charge controller is a DC to DC converter. The MPPT stage in the inverter is also a DC to DC converter.

As already highlighted above, there is a trend to apply MPPT to the module level and then string the outputs for a single inverter per string. Those mini MPPT systems are also basically DC to DC converters.

PV module performance can in this regard be individually tuned either by using a micro-inverter or via integrated solutions with power optimizers.

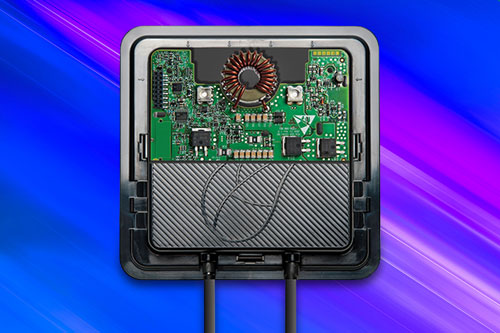

Smart module: Amphenol – Tigo junction box (Source: Amphenol)

What makes a smart module smart?

A smart module is a solar module with an integrated power optimizer embedded in the junction box. They are the result of collaborations of power optimizer developers and manufacturers with solar PV module manufacturers – in concurrence to increasing partnerships between manufacturers of solar modules with micro-inverter producers.

The smart module technology in fact refers to power optimization electronics-equipped junction boxes, therefore also coined smart junction box technology.

Like modules equipped with micro-inverters, the approach of smart modules is to isolate individual modules in order to improve overall system performance.

Different from traditional modules and solar module – micro-inverter combinations, the electronics are directly embedded in the module to offer direct module-level maximum power point tracking and thus power optimization, mitigating mismatch effects, output, and functionality monitoring, and flexible installation and replacement.

Advanced power optimizers feature voltage-target modes thus effectively maintaining the string’s voltage at a pre-defined optimal DC-AC inversion point.

This comes with the advantage of more precise and efficient string planning, allowing for even longer strings and thus larger possible installations, effectively increasing the revenue of installers and also letting system owners rejoice about more powerful systems.

All-in-all, system developers can directly use and install smart modules without calculating and sourcing micro-inverters which come with additional component costs and installation time as well – a plug’n power approach simplifying the overall supply chain.

Moreover, smart modules enable the implementation of systems with diverging structural and environmental conditions, considering multiple module tilts, orientations and base structures, and land contours on which the modules are to be installed and fixed.

Thus, smart modules allow for cost-efficient, material-saving circumvention of negative preconditions such as non-ideal rooftops or grounds with inherent shading and orientation difficulties.

Major companies providing smart module technology

The Forerunner and market leader in this field of module-level power electronics is Tigo Energy.

Their ES-Series junction boxes provide individual module power optimization technology, and module-level data for operational management and performance monitoring and are IP67 rated ad tested by ANSI and EN standards.

Recently, the California-based MLPE company set up its so-called TS4 Platform which basically is a flexible modular smart junction box that allows customers to configure their junction box features as per budget and requirements, from basic electronic connections up to power monitoring and module-level diagnostics.

This TS4 Platform series also includes an add-on solution called TS4-R which can be retrofitted to existing PV modules by connecting it to the junction box.

Another major company in this emerging PV sub-sector of smart module embedded power optimizer solutions is SolarEdge, which with its P-Series offers both residential and commercial smart module solutions, including retrofit products and embedded power optimizers.

Dinh

on 10 Mar 2017Jerry Stokes

on 14 Jul 2016Gurumoorthy

on 23 May 2016