Albedo

Bypass Diodes

Solar Glazing

Single Phase Versus Three Phase Power Supply

Three phase power supply

Single Phase Power Supply

Module Measurement without Load

Module Measurement with Load

[...]

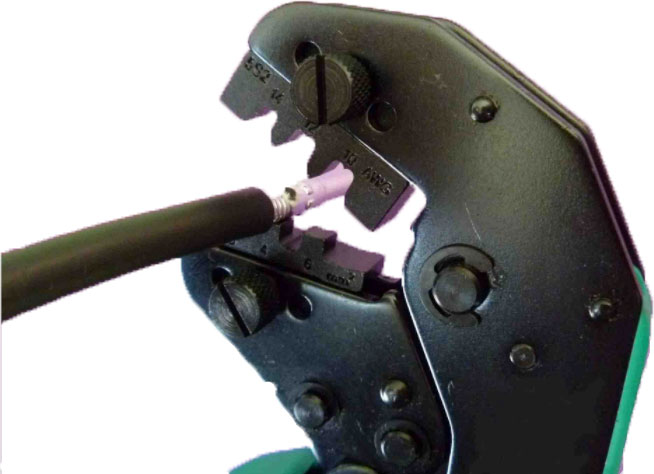

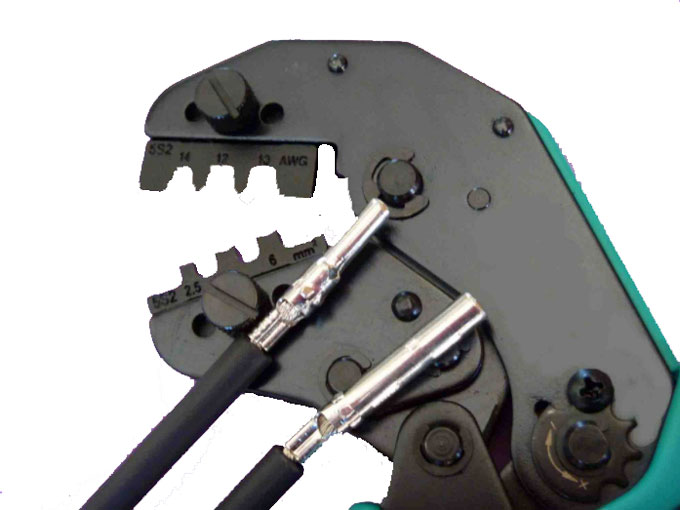

MC4 connector crimping tool[/caption]

MC4 connector crimping tool[/caption] MC4 connector crimping tool[/caption]

MC4 connector crimping tool[/caption]

David

on 01 Jul 2023