Power Conditioning System

PCB

Connectors without locking device

Connectors with Locking Device

Ingress Protection

Intermateability of Connectors

Solar Glass

Bus Wire and Tab Wire

[...]

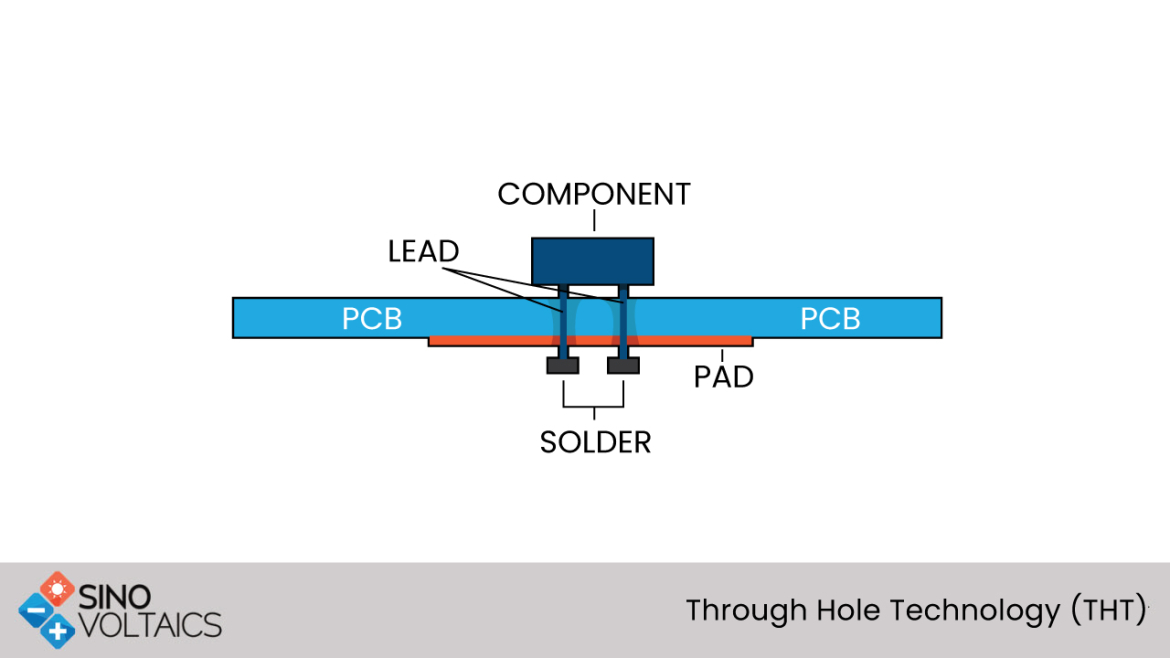

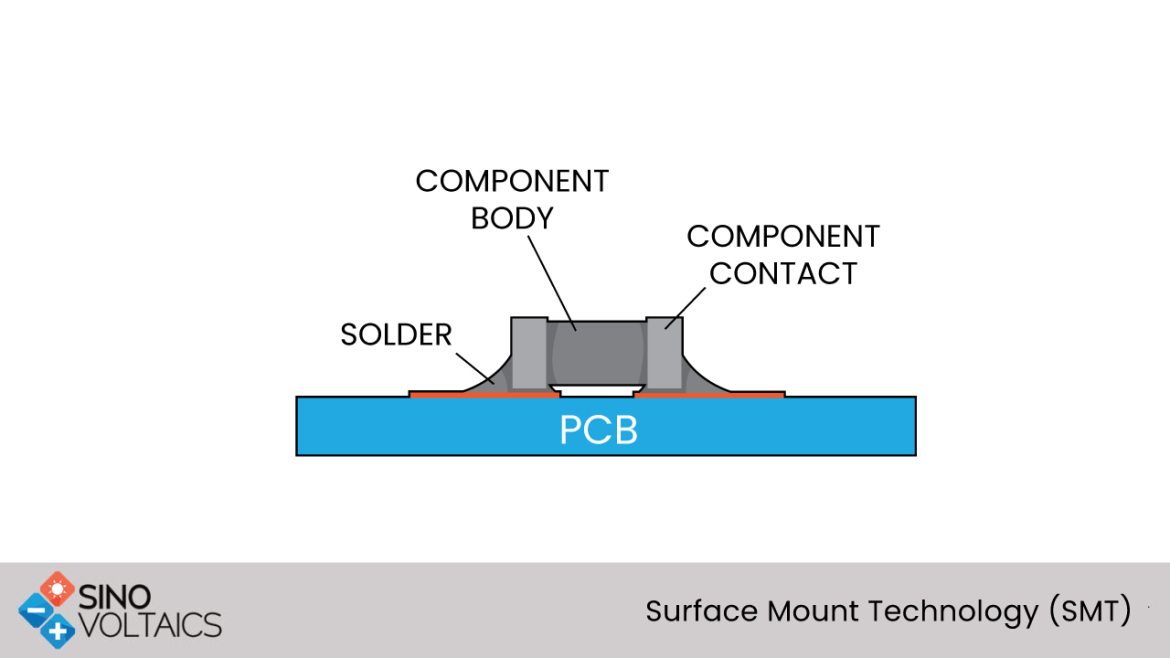

Components can be mounted in two ways. Through hole components are mounted by passing the wire leads through the board and soldering them to traces on the other side. Surface mount components are soldered by their leads to copper traces on the same side of the board.

Components can be mounted in two ways. Through hole components are mounted by passing the wire leads through the board and soldering them to traces on the other side. Surface mount components are soldered by their leads to copper traces on the same side of the board.