EVA Browning

Introduction

EVA Browning is defined as a change in color of the EVA film. EVA or ethylene vinyl acetate is used as an encapsulant in crystalline silicon PV modules. Browning in the modules happen when certain additives, used to prevent browning and enhance UV tolerance, start to disappear after losing strength against UV rays. This normally happens due to poor storage and handling methods. This can lead to bleaching and blistering of the EVA film and the solar back sheet often triggering corrosion in cell. A typical scenario of browning and corrosion is shown in figure 1 below.

Figure 1. Corrosion PV. Source: https://www.pi-berlin.com/en/eva-film-test.html

Figure 1. Corrosion PV. Source: https://www.pi-berlin.com/en/eva-film-test.html

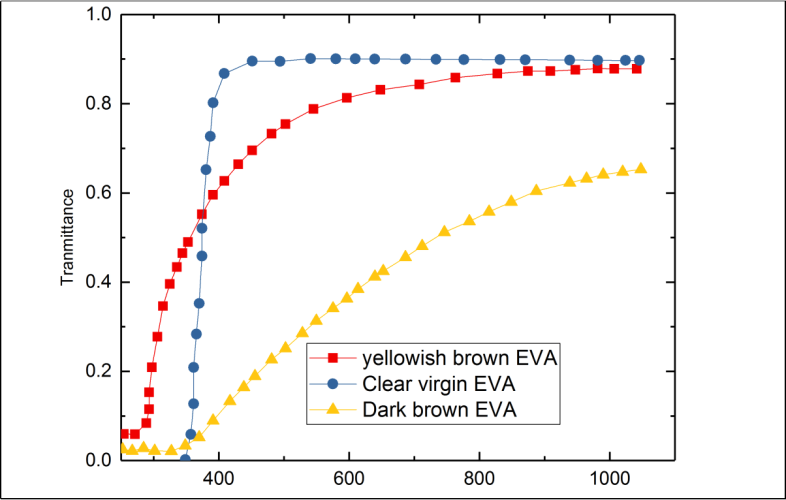

In addition to being an aesthetic problem browning also leads to a decrease in the module performance due to a high absorption in the EVA film as shown in the graph in Figure 2.

Figure 2: Wavelength-dependent transmission of virgin EVA, yellow EVA, and brown EVA (source: PV-manufacturing.org)

Figure 2: Wavelength-dependent transmission of virgin EVA, yellow EVA, and brown EVA (source: PV-manufacturing.org)Pattern of browning

It has been noticed that discoloration or browning is mostly inhomogeneous and follows spatial patterns but the patterns depend on the type of module construction. For example, for glass/back sheet modules the browning occurs in the center of the cell with prominent EVA areas normally referred to as doughnut ring patterns above each cell. Discoloration is rarely observed in the EVA between neighboring solar cells. For glass/glass module constructions, this EVA discoloration is more spatially uniform. Bad effects of EVA Browning

- Browning in PV modules can induce a power loss by up to 0.5%/year. This usually happens through a reduction of the short-circuit current of the module but the degradation rate due to this cause may reach about 10%/year for modules with concentrators.

- Cracking of cells can happen because of browning. It is to be noted that the browning of EVA may show patterns of clearer stripes or points over some cells. The location of these patterns has been shown to correlate with the cracks on the cells.

- Yellowing/browning has also been shown to produce acetic acid with UV exposure which corrodes solder bonds and electrical contacts that leads to increased leakage current through the encapsulant.

- EVA adhesion and shear also decrease significantly with EVA degradation

What can be done to remediate EVA browning?

EVA discoloration and browning can be reduced by:

- Usage of suitable additives

- Placing a UV blocking glass