Degradation of Solar Cell Performance Due To Microcracks

The impact of common solar panel defects such as microcracks in solar cells is a topic of significant concern in the field of photovoltaic technology. Here's a summary of the findings from the latest research papers:

1. Small Immediate Impact, Significant Long-Term Risk: Microcracks initially have a minimal effect on the power output of photovoltaic (PV) modules. However, their presence leads to mechanisms that cause power loss in solar cells and can be crucial for the performance of the module after artificial aging, potentially leading to significant power loss over time. [1]

2. Variable Power Loss Depending on Crack Type and Size: The output power loss due to microcracks varies widely, from 0.9% to 42.8%, depending on the type and size of the microcrack. Cracks in defective solar panels and their solar cell fingers, for instance, can increase power loss by at least 1.7%. [2]

3. Correlation with PV Hot-Spots: There is a substantial correlation between PV hot-spots and the presence of microcracks (measured as microcracks r/cm). These hot-spots are areas of elevated temperature in the solar cell, which can degrade its performance. [3]

4. Influence on Electrical and Mechanical Performance: Microcracks can drastically reduce both the electrical and mechanical performance of individual solar cells, leading to a decrease in overall module efficiency. [4]

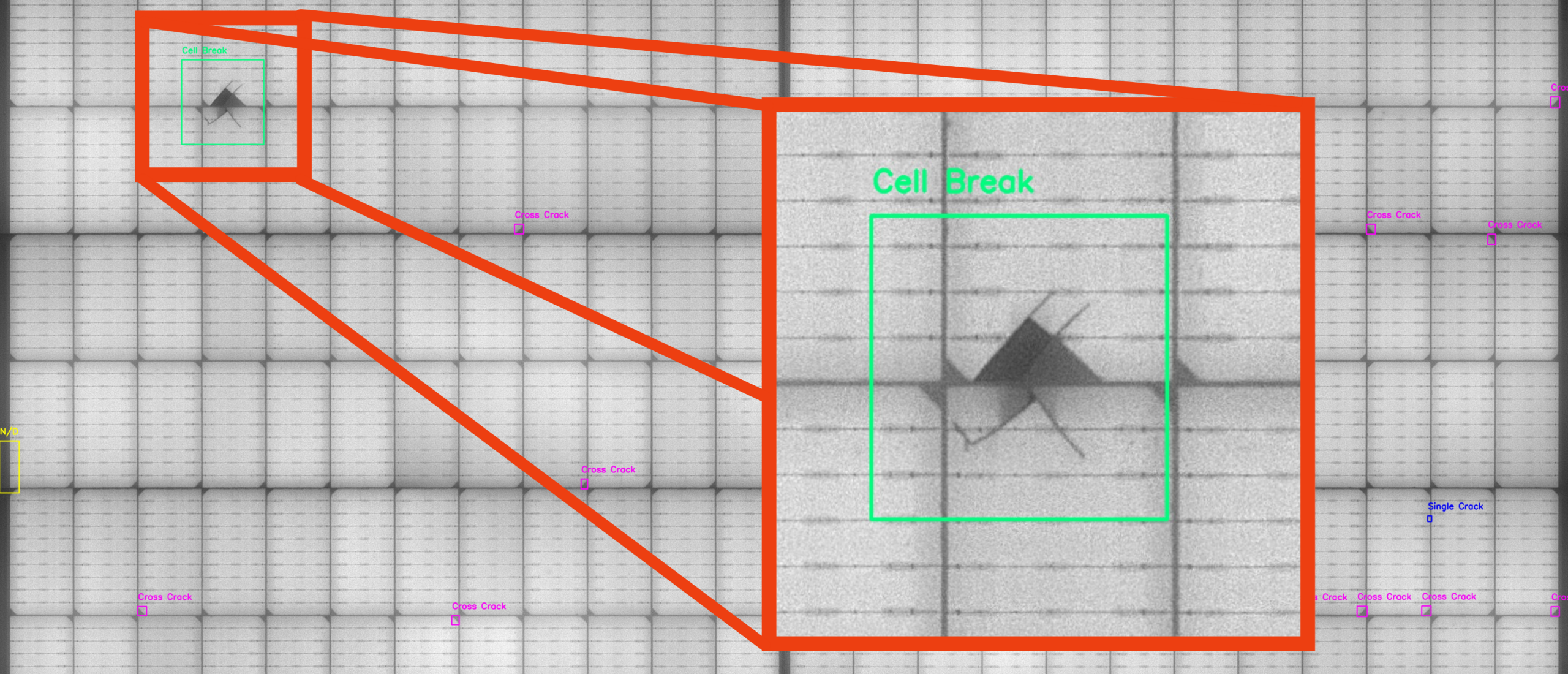

5. Detection and Prevention: Detecting microcracks early in the production process is crucial. Techniques like quantitative evaluation of electroluminescence images of solar cells (electroluminescence (EL) imaging) and photoluminescence (PL) imaging are effective in identifying these defects. Preventive measures include optimizing the production process to reduce the likelihood of microcrack formation. [5]

In conclusion, while a microcrack in modular solar cells panels might not immediately affect power output significantly, their long-term impact on the reliability and efficiency degradation of solar cells and the solar panels is substantial, necessitating careful monitoring and management in PV module production and maintenance for example by electroluminescence imaging of solar cells.

The potentially far-reaching impacts of micro cracks necessitates greater scrutiny than mere sampling. In the framework of its Zero Risk Solar approach to PV quality assurance, team Sinovoltaics performs 100% EL image analysis using its proprietary analysis software SELMA (Sinovoltaics EL Mass Analysis).

Sources:

1) Jung, Verena, and Marc Köntges. “Al/Ni : V/Ag Metal Stacks as Rear‐side Metallization for Crystalline Silicon Solar Cells.” Progress in Photovoltaics: Research and Applications, vol. 21, no. 5, Wiley, Feb. 2012, pp. 876–83. Crossref, https://doi.org/10.1002/pip.2169.

2) Dhimish, Mahmoud. “Micro Cracks Distribution and Power Degradation of Polycrystalline Solar Cells Wafer: Observations Constructed From the Analysis of 4000 Samples.” Renewable Energy, vol. 466–477, 1 Jan. 2020, https://doi.org/10.1016/j.renene.2019.06.057.

3) Dhimish, Mahmoud. “Micro Cracks Distribution and Power Degradation of Polycrystalline Solar Cells Wafer: Observations Constructed From the Analysis of 4000 Samples.” Renewable Energy, vol. 466–477, 1 Jan. 2020, https://doi.org/10.1016/j.renene.2019.06.057.

4) Abdelhamid, Mahmoud, et al. “Review of Microcrack Detection Techniques for Silicon Solar Cells.” IEEE Journal of Photovoltaics, vol. 514–524, no. 1, 1 Jan. 2014, https://doi.org/10.1109/jphotov.2013.2285622.

5) Teo, Teow Wee, et al. “Recent Advancements in Micro-crack Inspection of Crystalline Silicon Wafers and Solar Cells.” Measurement Science and Technology, vol. 081001, no. 8, 11 June 2020, https://doi.org/10.1088/1361-6501/ab8088.