Fluxing Agents: Types and Applications

Tabbing Ribbons: Design and Purpose

VOC-Free Fluxing Agents

Bussing Ribbons: Design and Purpose

Fiberglass as PV Module Superstrate

Ethylene Tetrafluoroethylene

Tin/silver/copper (SnAgCu)

Tin/Silver Alloy

[...]

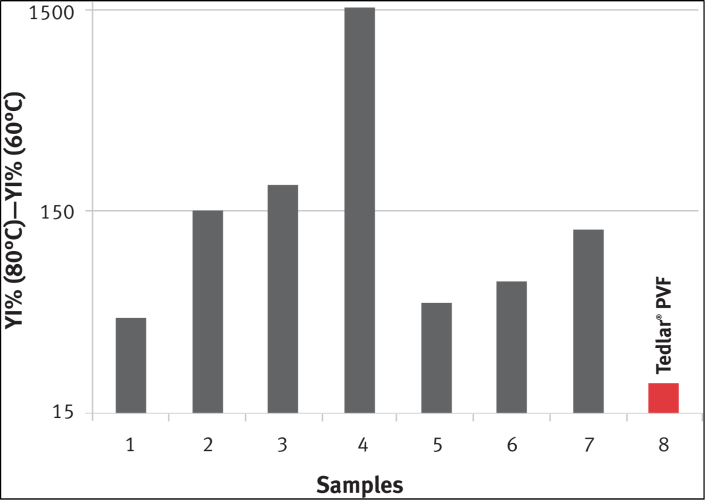

Figure 1: Results from Fraunhover study (source: PVDiagnosis)[/caption]The results of Franhouver study are represented in the graph above. Backsheet yellowing of different types of materials exposed to a constant amount of UV is shown. Variation of yellowing is measured at two different temperatures (60C and 80C). The following observations was concluded from the study:

Figure 1: Results from Fraunhover study (source: PVDiagnosis)[/caption]The results of Franhouver study are represented in the graph above. Backsheet yellowing of different types of materials exposed to a constant amount of UV is shown. Variation of yellowing is measured at two different temperatures (60C and 80C). The following observations was concluded from the study: