TOPCon + New Solar Cell Technology: The Next Leap in Photovoltaics

Introduction

As the global solar market pushes for higher efficiency, longer lifespans, and lower LCOE (Levelized Cost of Energy), the advantages of solar energy continue to grow and a new wave of photovoltaic (PV) innovation is emerging. Among the most promising advancements is TOPCon (Tunnel Oxide Passivated Contact)—a next-generation solar cell architecture that is rapidly gaining traction in commercial production. But TOPCon is just one part of the evolving solar tech story. From tandem cells to perovskites, new materials and techniques are reshaping the future of solar power.

In this article, we explore the rise of TOPCon solar cell technology, how it compares to PERC and other architectures, and what other innovations are converging to define the next frontier of solar cell development.

What is TOPCon Technology?

TOPCon is an advanced solar cell structure developed to address the efficiency limits of traditional P-type PERC (Passivated Emitter and Rear Contact) cells. The architecture is based on N-type monocrystalline silicon wafers and uses a thin tunnel oxide layer between the wafer and a polycrystalline silicon passivating contact.

Key Features of TOPCon:

- Higher efficiency: Lab efficiencies >25%, commercial modules approaching 24%+

- Low degradation: Excellent resistance to Light-Induced Degradation (LID) and Light and elevated Temperature Induced Degradation (LeTID)

- Bifacial performance: High bifaciality (80%+), ideal for bifacial modules and ground-mounted systems

- Scalability: Compatible with existing PERC production lines with upgrades

TOPCon offers a low-cost, high-efficiency upgrade path for manufacturers seeking to stay competitive without a complete factory overhaul.

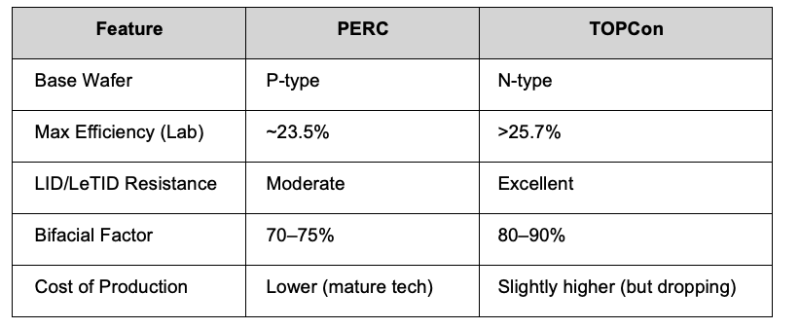

TOPCon vs PERC: A Comparative Look

While PERC still dominates in many markets due to cost and scale, TOPCon is fast closing the gap—especially as upstream silicon prices drop and module buyers demand higher energy yield per square meter.

What’s New in Solar Cell Technology?

While TOPCon is currently leading commercial advancements, several emerging technologies are poised to redefine efficiency records and manufacturing paradigms.

1. Heterojunction (HJT) Solar Cells

- Combines crystalline silicon with amorphous silicon layers

- Record efficiency >26%

- Excellent temperature performance

- Manufacturing costs and silver paste usage remain challenges

2. Perovskite Solar Cells

- Lightweight, printable, and potentially ultra-low-cost

- Efficiency surpassed 26% in lab tandem configurations

- Stability, toxicity (lead content), and scaling are under intense research

3. Tandem Solar Cells

- Layering two or more cell types (e.g., perovskite + silicon) to exceed Shockley–Queisser limit

- Theoretical efficiencies >30%

- Expected to play a major role in next-gen utility-scale and space PV

4. xBC + TOPCon Hybrid Cells

Interdigitated Back Contact (IBC) cells with TOPCon rear passivation are also in development. This hybrid design aims to combine the aesthetic and performance advantages of IBC with the efficiency gains of TOPCon (TBC/ZEBRA), though complexity in manufacturing still limits scale-up. Other combinations like PERC back contact (HPBC), Heterojunction Back Contact HBC (EU Pilatus).

The Future: Toward 30%+ Efficiency?

The convergence of TOPCon, tandem, and perovskite technologies may lead to the first commercially viable modules with efficiencies over 30% in the coming decade. Leading manufacturers such as JinkoSolar, LONGi, Trina Solar, and others are investing heavily in R&D to commercialize these solutions at scale.

At the same time, innovations in AI-based quality control, advanced encapsulants, and recyclable materials are reshaping the sustainability and circularity of solar products.

Real-World Trends: TOPCon Adoption Accelerates

According to data from InfoLink and PV Tech:

- Over 40 GW of TOPCon capacity was operational by the end of 2024

- Major expansions are underway in Southeast Asia, China, and Europe

- Module prices for TOPCon have dropped by 15–20% over the past year, narrowing the gap with PERC

Expect more developers to specify TOPCon modules for utility and C&I projects, especially in hot climates and bifacial setups.

Challenges with TOPCON PV modules

Moisture Sensitivity & Encapsulation Compatibility

- Issue: The passivated rear side of TOPCon cells involves a delicate stack of tunnel oxide and doped polysilicon. Moisture ingress can degrade the thin tunnel oxide layer, impacting passivation and increasing recombination.

- Implication: Higher susceptibility to PID (potential-induced degradation), especially PID-s (shunting), compared to standard PERC.

- Mitigation: Enhanced edge sealing, use of advanced encapsulants (like POE instead of EVA), and moisture barrier backsheets.

Light and Elevated Temperature-Induced Degradation (LeTID)

- Issue: Even though TOPCon is based on n-type silicon (which is inherently immune to LID due to the absence of boron-oxygen defects), LeTID has been observed, particularly in certain n-type wafers (phosphorus-doped Czochralski).

- Cause: Hydrogen-related metastable defects that activate under illumination and heat (e.g., 75°C and sunlight).

- Implication: Power loss over the first 500–1000 hours of operation.

- Mitigation: Optimized firing profiles during cell manufacturing and hydrogen gettering processes.

Metallization and Contact Degradation

- Issue: The polysilicon layers in TOPCon have higher sheet resistance than in PERC, and require different metallization schemes. Silver paste interaction with polysilicon can degrade over time, especially under damp heat or thermal cycling.

- Implication: Increased series resistance and contact degradation over time.

- Mitigation: Development of compatible Ag pastes and firing processes to form stable contacts without degrading passivation.

Glass/Backsheet and Bifacial Configuration Risks

- Issue: Most TOPCon modules are bifacial, often glass-glass. These have different aging characteristics, including:

- Microcrack propagation risks due to more rigid lamination.

- Delamination and yellowing in high-UV or high-humidity environments.

- Implication: Higher BOS risk in mechanical load zones and harsher climates.

- Mitigation: Rigorous mechanical load testing, hail impact qualification (e.g., IEC TS 62782), and material compatibility checks.

Encapsulation-Induced Passivation Loss

- Issue: During lamination, high temperature can degrade the ultra-thin SiOx tunnel oxide or induce strain between layers (SiOx/poly-Si/Si).

- Implication: Degraded passivation leads to long-term performance degradation.

- Mitigation: Tight control over lamination process temperature and time.

UV Degradation of Rear-Side Passivation

- Issue: Rear-side passivation stacks (often exposed in bifacial designs) may degrade under prolonged UV exposure if encapsulants are not UV-stable.

- Implication: Increased rear-side recombination; lower bifacial gains over time.

- Mitigation: Use of UV-blocking or UV-stable materials; aging tests simulating rear-side exposure.

Manufacturing Maturity

- Issue: Many manufacturers have rapidly transitioned to TOPCon from PERC, but process control and yield management are less mature.

- Implication: Higher cell-to-cell variation, reliability inconsistencies across batches.

- Mitigation: Strong QA/QC, upstream wafer quality control, and supplier audits.

Conclusion

TOPCon is no longer just a lab breakthrough—it’s now a commercially viable, high-efficiency solution that's reshaping global solar markets. And with other promising technologies like tandem cells and perovskites maturing rapidly, the next few years will likely usher in a new golden era for PV innovation. Nonetheless there are challenges that can be addressed with smart mitigation strategies by using services like that of Sinovoltaics.

If you're a developer, EPC, or investor, now is the time to get ahead of the curve. Evaluate your module options carefully, and stay informed as solar cell technology continues its rapid evolution. Ensure you're making the right choice—explore our PV Module Quality Control Inspections (solar inspection services) to safeguard your investment.