LFP battery

Energy Storage Market Risks: Cobalt vs Sodium Ion Batteries

Stages of The Thermal Runaway Process in Lithium Batteries

Materials for Lithium-Ion Battery safety

Lithium-ion battery safety Concerns

Why Do We Need Energy Storage?

Li-ion Batteries, Scales of Storage and Key Terminologies

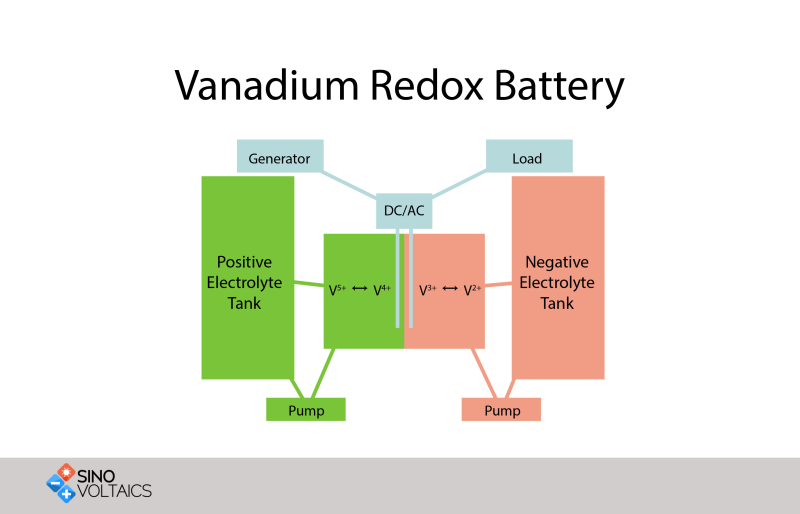

Battery Types for Energy Storage Applications