Energy Storage Market Risks: Cobalt vs Sodium Ion Batteries

Introduction

One of the common risks identified with Lithium-Ion batteries is the difficulty in procuring cobalt. What is cobalt used for? Cobalt is a critical metal found in the Earth's crust, usually found as a chemical compound. It has been used for centuries in sculpture, bronze, and ceramic artwork for its rich blue color.

Cobalt-based artwork

Cobalt-based artwork

Li-Ion batteries, especially those used in electric vehicles and high-power energy storage applications often use a graphite anode and a cathode made out of Lithium Cobalt Oxide (Li-Co-O2). Cobalt is used as a stabilizing element that allows Lithium to be removed and re-added as part of the charging–discharging cycle without affecting the physical structure of the cathode. Hence it is an important component in the electrochemical setup of the battery cell. In fact, the cells with the highest specific energy densities, Lithium Cobalt Oxide (LCO), Lithium Nickel Cobalt Aluminium Oxide (NCA), and Nickel Manganese Cobalt (NMC), all rely extensively on the use of cobalt.

Potential Risks

Is cobalt safe? Despite being a well-suited metal, the use of cobalt has a number of issues associated with it. In fact, it is considered to be the highest supply chain risk for Electric Vehicles in the short to medium term. For the highly popular NMC technology, with as much as 20 kg of cobalt in a 100-kWh battery pack, it can form 20% of the total weight of the cathode and has significant implications for energy storage. In LCO cells, it can constitute over 50% of the cathode.

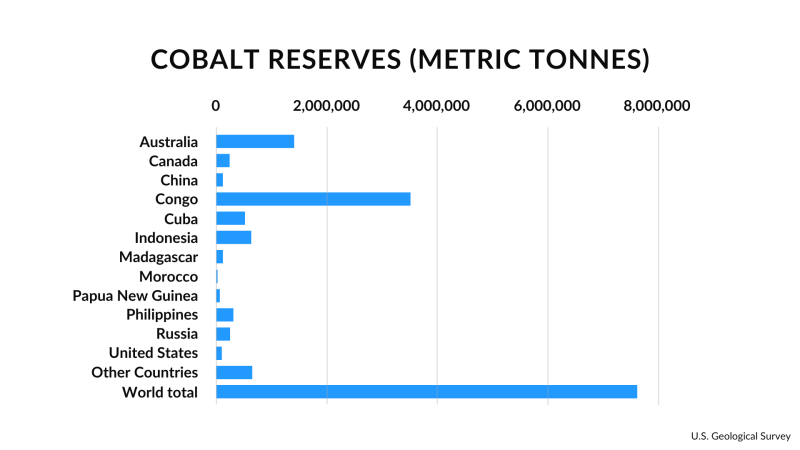

A United States Geological Survey report, the Mineral Commodity Summaries 2022, indicates a strong imbalance in the geographical distribution of cobalt.

As the graph above shows, the Democratic Republic of Congo (DRC) accounts for about 50% of the world's cobalt reserves. This is followed by Australia and Indonesia with about 15% and 6% of the total, respectively.

The following three main risks of using cobalt will be discussed in this article - societal, economic, and energy security.

1. Societal Risk:

Numerous studies show that cobalt mining is associated with a high environmental and human cost of extraction.

Source: www.worldsaid.com | AFP

Source: www.worldsaid.com | AFP

Close to 15% of the metal used today is sourced through “artisanal mines” in DRC. These artisanal miners hand dig relatively high-grade ores when compared to industrial methods. However, these operations are close to impossible to monitor for ESG compliance. Unfortunately, this may lead to extensive use of child labour, exploitation, and hazardous working conditions. As with mining in general, the environmental impact of cobalt mining, especially the smaller artisanal mines is well documented.

2) Security Risk:

Much of the cobalt extracted today is a by-product of copper mines. Hence its production is closely tied to copper demand. But due to the relatively stable demand for copper, its production does not get ramped up and as a result, cobalt extraction remains low. In addition, the high concentration of cobalt reserves in certain areas of the world proposes a significant risk to the supply chain. The socio-political instability in DRC and its resulting impact on trade is a particularly important consideration. In addition, most of these mining operations as well as the overwhelming majority of the cobalt refining are controlled by a single geopolitical player, leading to further security risks.

3) Economic Risk:

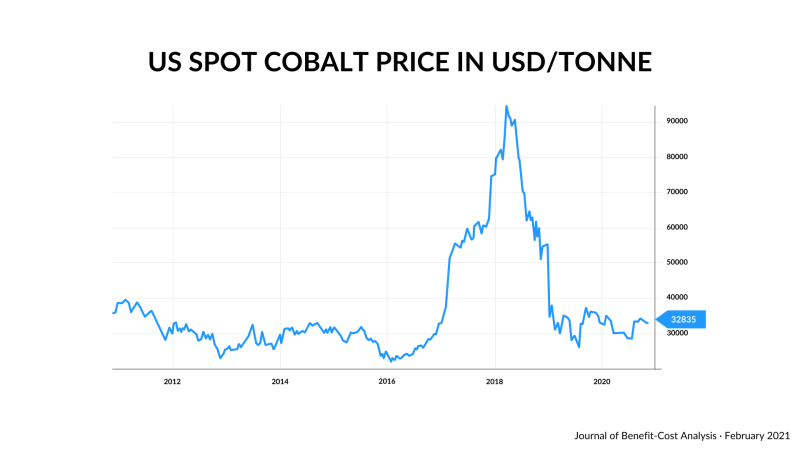

For the reasons described above, the market price of cobalt is not very stable. The graph below shows the extreme cost fluctuations in just a few years. The extreme increase in cobalt prices was a result of the cobalt supply risk perception and the sharp decline was in part due to industry announcements about the move towards “cobalt-free” batteries.

Source: Journal of Benefit-Cost Analysis · February 2021

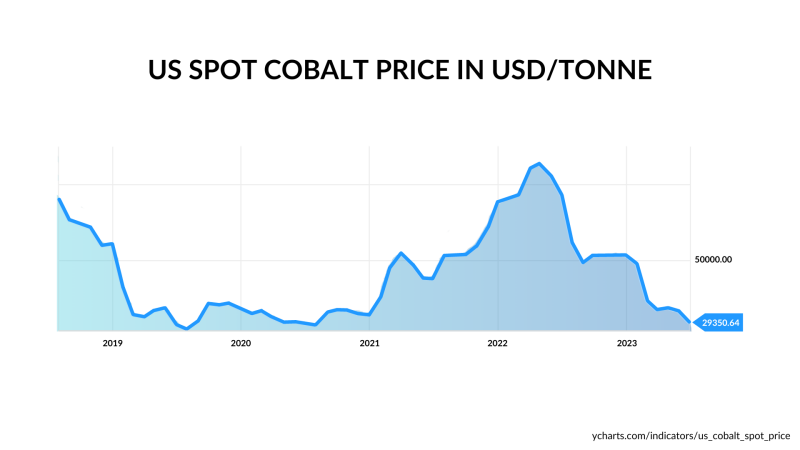

Nonetheless, prices once again showed extreme price fluctuations during the post-pandemic logistical instability.

Source: https://ycharts.com/indicators/us_cobalt_spot_price

Emerging Solutions

The combination of the above risks associated with cobalt has led to a search for solutions to sustain growth in the energy storage market. One of the prominent technological solutions being pursued is the development of reduced cobalt or even cobalt-free batteries. While NMC and NCA batteries rely on cobalt mixing with other metals to reduce the amount of the element required compared to LCO batteries, other alternatives such as LFP (Lithium Iron Phosphate) eliminate the use of cobalt entirely. Each of these technologies has its pros and cons but in general, higher cobalt concentrations allow for higher charge/discharge rates thus making them highly attractive for high-power applications such as EVs.

For stationary storage applications, LFP has emerged as the technology of choice and its rapid adoption, associated with massive investments in China's manufacturing capabilities, has led to drastic cost reductions over the last few years. Companies such as Tesla and Panasonic are also pushing for the use of LFP cells in the EV segment and R&D efforts are targeting mass adoption of this technology in affordable consumer vehicles in addition to the existing stationary storage market. The follow-on risk of this technology development is that as LFP cells get better, they may get redirected from stationary storage to the much larger and lucrative EV market.

Sodium-ion battery and other batteries non-toxic: A Solution to Cobalt Risks in Energy Storage Market?

This is leading to increased interest in non-Li-Ion storage technology such as Sodium Ion batteries, Redox Flow batteries, or even Metal Hydrogen batteries. Nonetheless, due to the many performance benefits of cobalt-based batteries (higher energy density, higher C-rates), they will continue to form a large part of the energy transition primarily in the mobility space. Hence the risks associated with cobalt will remain an Achilles heel for the growth of storage and technological as well as non-technological solutions are actively being developed to ensure a sustainable supply of this important metal.